Anti-Scratch PVC Surface Layer Suppliers

information to be updated

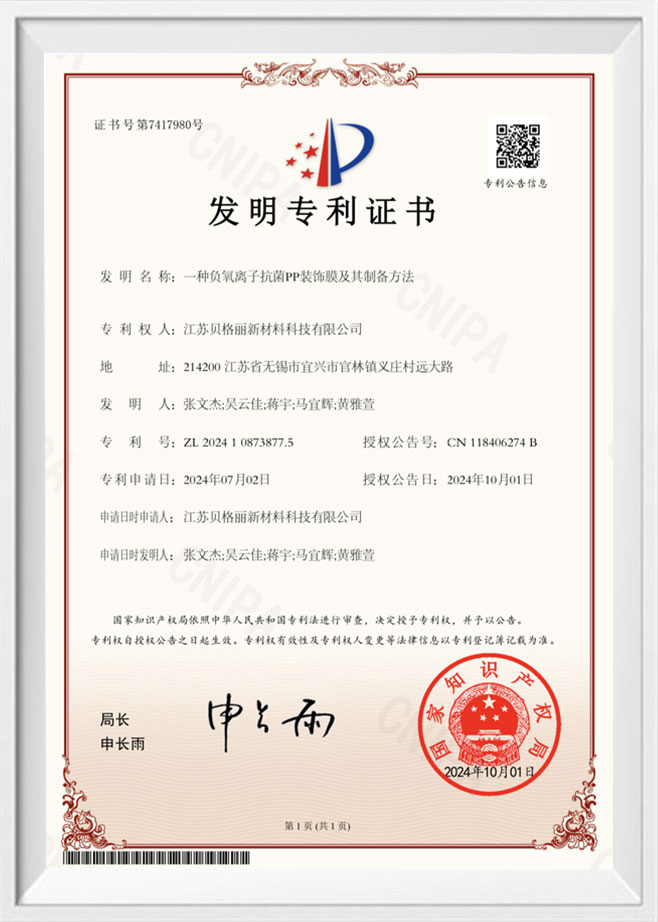

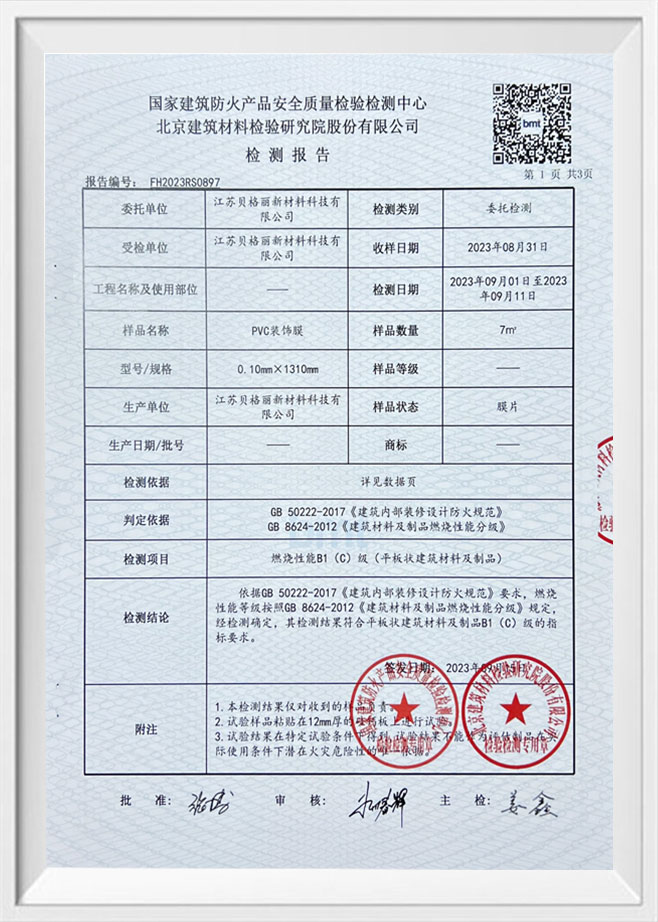

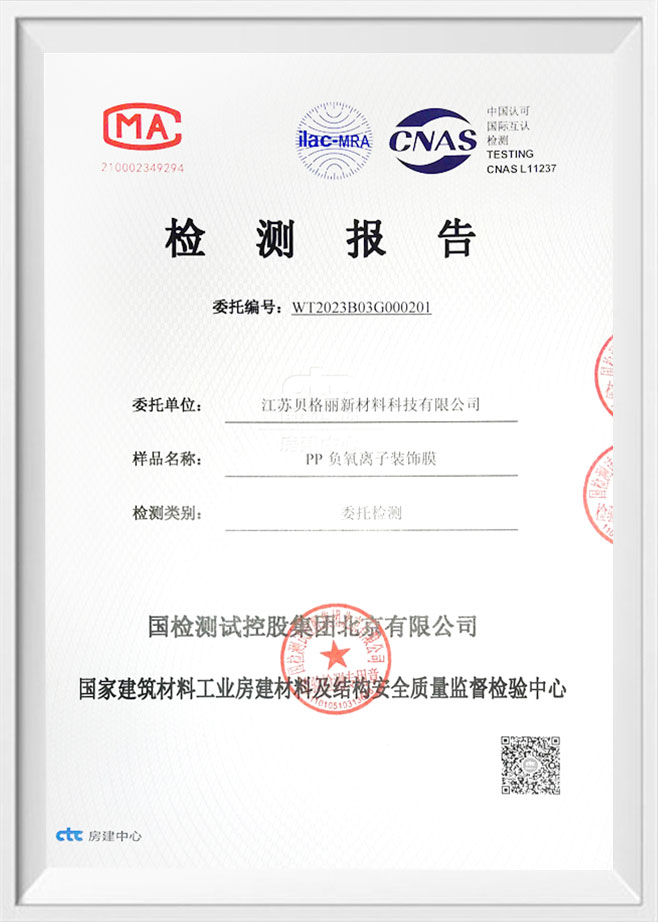

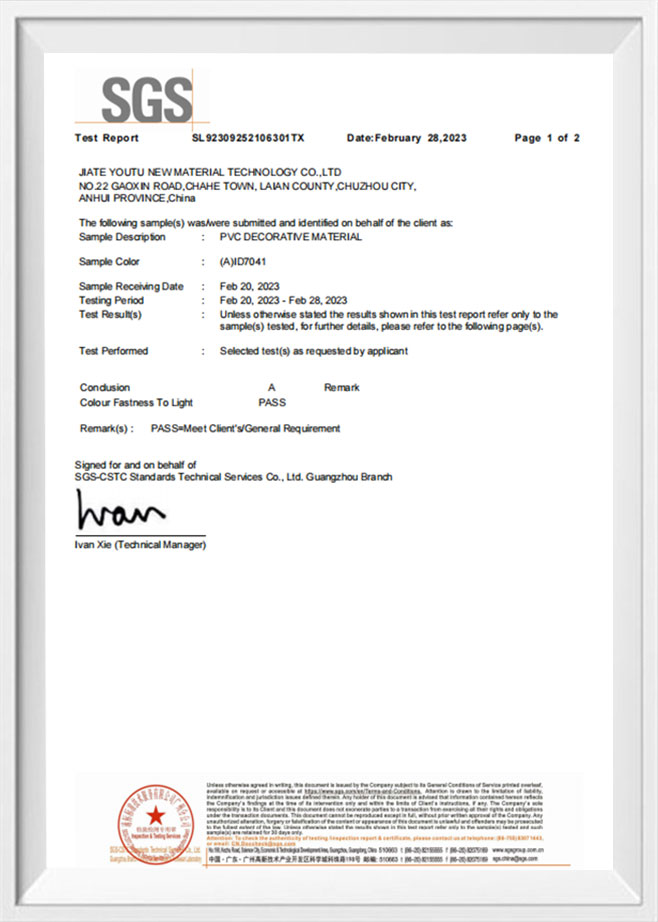

We have our own coating production line, using advanced production technology and a number of patented technologies, which can provide you with many different types of stain-resistant, scratch-resistant, skin-feeling, and yellowing-resistant PVC facial masks.

About Us

Jiaxing Xuanyi International Trade Co.,Ltd is a professional decorative film manufacturer located in Jiaxing City, Zhejiang Province. As Anti-Scratch PVC Surface Layer Suppliers and Anti-Scratch PVC Surface Layer Company in China. We have our own raw material factory, calender factory, and Coating factory, forming a unique supply chain that enables us to achieve maximum cost control and offer competitive prices and high-quality products directly.

Jiaxing Xuanyi mainly engages in producing all kinds of decorative film for vacuum press, flat lamination, and profile wrapping furniture, and the interior decoration industry. Products include matte solid color series, matte wood grain series, high-gloss solid color series, high-gloss wood grain series, anti-scratch series, soft touch series, etc.

Jiaxing Xuanyi products are widely used in domestic and abroad markets as indoor and outdoor decoration materials in membrane doors, kitchen cabinets, and other furniture industries. We offer Wholesale Anti-Scratch PVC Surface Layer. Equipped with advanced facilities and professional technical experts, Jiaxing Xuanyi is committed to supplying high-quality decorative films at competitive prices.

The precise instrument, together with the cautious attitude, embodies the connotation of the “Rigorous”. Jiaxing Xuanyi adopts an international quality management mode and guarantees the quality of decorative film via advanced inspection and measurement methods. Adheres to the Value of “Profession, quality, cooperation, win-win situation”, Jiaxing Xuanyi is actively pioneering in unknowing fields through technological innovation oriented to the global market based on its long-accumulated comprehensive technological strength, to continuously offer various products that can improve people’s lives and promote the progress of the whole society.

News

-

Industry News 2026-02-28

Understanding PVC, PP, and PET Decorative Films: An Overview PVC, PP, and PET decorative films are polymer-based surface covering materials manufactured in continuous roll form and...

View More -

Self Adhesive Film Wallpaper: Installation Methods, Surface Compatibility, and Long-Term PerformanceIndustry News 2026-02-19

Material Structure and Adhesive Technology Behind Self Adhesive Film Wallpaper Self adhesive film wallpaper is manufactured as a multi-layer decorative system that integrates a pri...

View More -

Industry News 2026-02-12

ABS edge banding is widely used in modern furniture and cabinet manufacturing to protect panel edges, improve visual consistency, and extend service life. Made from acrylonitrile b...

View More

Industry Knowledge

How Anti-Scratch PVC Surface Layers Are Tested and Controlled for Lasting Quality and Reliability

Ensuring consistent surface performance is a key challenge in the manufacturing of Anti-Scratch PVC Surface Layers. Customers across sectors—from automotive interiors to consumer electronics—demand coatings that not only look good initially but continue to perform after extended use. Delivering this level of reliability requires more than just good materials; it depends on strict testing protocols, reliable quality control systems, and a production environment that minimizes variation from batch to batch.

A properly engineered anti-scratch PVC surface needs to resist mechanical abrasion, chemical contact, and environmental aging. At our facility, we design coatings with this full performance profile in mind and evaluate them using industry-recognized methods like pencil hardness tests, Taber abrasion testing, and solvent resistance analysis. These tests simulate actual handling conditions to ensure that the coating layer won’t degrade prematurely under normal use.

We also rely on accelerated aging simulations to track how color stability and scratch resistance hold up over time. Ultraviolet exposure, high-humidity environments, and thermal cycling are all used to mimic months or even years of wear in just a few days. These procedures help us refine both our base formulations and the functional additives that go into each anti-scratch PVC layer, keeping product performance predictable.

Beyond lab tests, real-world validation is essential. We often collaborate with customers to test coated film samples in their intended application environments. Whether it’s surface panels for passenger vehicles or protective coverings for handheld electronics, our coatings are expected to maintain tactile quality and resistance to blemishes under continuous use. That’s why every coating recipe we produce undergoes strict internal release criteria before scaling up.

Quality control is built into every stage of our coating line—from raw PVC resin selection to final surface treatment. We monitor coating thickness, curing behavior, and adhesion strength in-line, using sensor-based controls and manual inspections. Any irregularities are flagged immediately to prevent defective material from moving downstream. The goal is not just to meet specifications but to maintain long-term consistency in every anti-scratch surface layer produced.

We’ve also invested in traceability systems that connect material batches to their process parameters and test results. This means that if any performance issue arises in the field, we can trace the root cause quickly and make immediate adjustments. That level of feedback is especially important in high-volume applications where performance failure is costly—not just financially but in terms of reputation.

Another critical part of anti-scratch surface development is balancing durability with aesthetics and texture. A high-performance film isn’t useful if it feels too rigid or visually unappealing. That’s why our coating line integrates both technical and sensory evaluations. Parameters like gloss level, friction coefficient, and even “skin feel” are tuned carefully without compromising wear resistance. This type of controlled design is what sets premium-grade Anti-Scratch PVC Surface Layers apart from standard ones.

Since we handle both coating formulation and application in-house, we can respond quickly to new requirements or changes in customer specs. Whether the adjustment is to meet a new abrasion test standard or to modify surface gloss to match a design brief, we have the flexibility and technical base to execute it without long lead times. That adaptability is a key reason customers rely on us as a long-term supplier, not just a material vendor.

We believe product consistency is the most valuable feature of any anti-scratch PVC coating. While innovation matters, repeatable quality gives customers the confidence to scale their own products without added risk. By combining robust process control with forward-looking development, we provide not only a surface solution, but a trusted technical partnership.

If you're looking for a reliable supplier who can offer proven surface protection, stable lead times, and responsive technical support, our anti-scratch PVC solutions are built to meet those expectations—with every roll, every time.

English

English Español

Español عربى

عربى