Super Matte Soft Touch PVC Decorative Film Suppliers

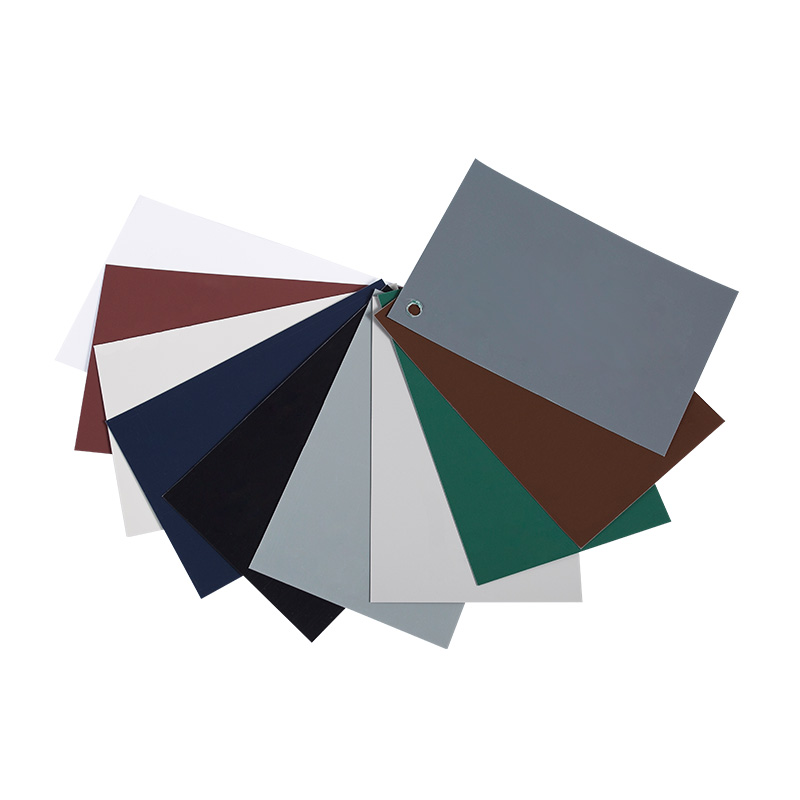

Soft-touch pvc decorative film is thermal lamination film with a soft feel or velvety texture. These films have an anti-scuff surface that enhances and thus protects the appearance of the laminated product. Primarily designed for one-sided lamination, soft-touch laminates are also used for double-sided lamination. Owing to its superior tactile properties, soft-touch lamination film provides a pleasant and intense velvety effect similar to peach skin. Usually soft touch lamination films finds applications in vacuum pressing doors, furniture, wall panel, kitchen cabinets, baseboard, home decor etc. Our soft-touch PVC film has the feeling of baby skin when you touch it; it is smooth like silk, with a matte effect, and a competitive price.

About Us

Jiaxing Xuanyi International Trade Co.,Ltd is a professional decorative film manufacturer located in Jiaxing City, Zhejiang Province. As Super Matte Soft Touch PVC Decorative Film Suppliers and Super Matte Soft Touch PVC Decorative Film Company in China. We have our own raw material factory, calender factory, and Coating factory, forming a unique supply chain that enables us to achieve maximum cost control and offer competitive prices and high-quality products directly.

Jiaxing Xuanyi mainly engages in producing all kinds of decorative film for vacuum press, flat lamination, and profile wrapping furniture, and the interior decoration industry. Products include matte solid color series, matte wood grain series, high-gloss solid color series, high-gloss wood grain series, anti-scratch series, soft touch series, etc.

Jiaxing Xuanyi products are widely used in domestic and abroad markets as indoor and outdoor decoration materials in membrane doors, kitchen cabinets, and other furniture industries. We offer Wholesale Super Matte Soft Touch PVC Decorative Film. Equipped with advanced facilities and professional technical experts, Jiaxing Xuanyi is committed to supplying high-quality decorative films at competitive prices.

The precise instrument, together with the cautious attitude, embodies the connotation of the “Rigorous”. Jiaxing Xuanyi adopts an international quality management mode and guarantees the quality of decorative film via advanced inspection and measurement methods. Adheres to the Value of “Profession, quality, cooperation, win-win situation”, Jiaxing Xuanyi is actively pioneering in unknowing fields through technological innovation oriented to the global market based on its long-accumulated comprehensive technological strength, to continuously offer various products that can improve people’s lives and promote the progress of the whole society.

News

-

Industry News 2026-02-28

Understanding PVC, PP, and PET Decorative Films: An Overview PVC, PP, and PET decorative films are polymer-based surface covering materials manufactured in continuous roll form and...

View More -

Self Adhesive Film Wallpaper: Installation Methods, Surface Compatibility, and Long-Term PerformanceIndustry News 2026-02-19

Material Structure and Adhesive Technology Behind Self Adhesive Film Wallpaper Self adhesive film wallpaper is manufactured as a multi-layer decorative system that integrates a pri...

View More -

Industry News 2026-02-12

ABS edge banding is widely used in modern furniture and cabinet manufacturing to protect panel edges, improve visual consistency, and extend service life. Made from acrylonitrile b...

View More

Industry Knowledge

How to Apply Super Matte Soft Touch PVC Decorative Film Effectively on 3D Surfaces and Complex Shapes

Applying Super Matte Soft Touch PVC Decorative Film to 3D surfaces requires more than just standard lamination skills—it demands a precise understanding of how the material behaves under heat, pressure, and contour stress. Unlike flat lamination, vacuum pressing on routed MDF panels, curved cabinet doors, or textured moldings introduces several challenges, especially when trying to preserve the signature soft-touch texture and uniform matte appearance without flaws. Manufacturers working with soft touch super matte decorative films quickly learn that success depends on proper surface preparation, temperature calibration, and careful forming control throughout the process.

Soft-touch films with ultra-matte finishes are more sensitive to surface imperfections, so substrate quality plays a critical role. A fine, dust-free MDF or similar board with consistent porosity ensures better adhesion and reduces risks of bubbling. Before lamination, the substrate must be conditioned and free from residual moisture, as temperature-induced vapor release during vacuum pressing can lead to delamination or wrinkling beneath the film’s surface. Consistency in board density across production batches also helps maintain uniformity in forming depth and pressure distribution.

During the vacuum forming process, film temperature must be tightly controlled to activate the adhesive layer without degrading the soft-touch surface. Most Super Matte Soft Touch PVC Decorative Films respond well to preheating in the range of 115°C to 130°C, but the specific values can vary depending on thickness and backing layer composition. Excessive heat can cause glossing on corners or dull the velvet-like effect that defines the product. Uneven heating can also make the film stretch too much on corners while remaining stiff in flatter areas, which leads to surface tension differences and visible stress marks.

Equally important is controlling the vacuum cycle time and suction power. A longer softening time allows the film to relax into detailed grooves and radii, but if suction starts too early, it may pull the film before it becomes pliable, leading to bridging or tearing. Soft touch supre matte decorative films are typically thicker and less elastic than standard gloss or embossed films, so achieving precise corner coverage without over-stretching requires experience and carefully maintained press settings.

Film memory is another factor that can’t be ignored. After cooling, poorly formed sections may show signs of retraction or lifting, especially around sharp contours. Using quality adhesive systems that activate fully within the film's optimal working range helps stabilize the bond. In some cases, edge priming or selective use of edge-wrap adhesives can enhance long-term adhesion without affecting the surface softness. It’s crucial to avoid hard rollers or direct surface pressure after pressing, as these can leave marks that are nearly impossible to repair due to the non-reflective finish of super matte films.

The tooling used in vacuum forming also affects the final result. Well-designed molds with softened edges and gradual curves reduce film stress and lower the chance of tearing or uneven lamination. Film tension should be minimized before pressing by adjusting frame placement and avoiding over-stretching while loading. Even airflow distribution inside the press chamber contributes to more predictable forming behavior, especially for larger panel formats.

Post-forming care is often underestimated but vital to maintaining the soft-touch effect. After the pressing cycle, allow panels to cool naturally to prevent thermal shock or moisture condensation between the film and substrate. Do not stack panels while still warm, and avoid cleaning or wiping the surface for several hours. While the soft-touch finish is engineered for wear resistance, it is still susceptible to pressure deformation immediately after forming, when the adhesive layer is still settling.

Customers often ask why their first few batches don't match showroom samples. The answer often lies in the setup details—temperature drift, inconsistent board quality, or improper handling during forming can make a significant difference. That's why we always recommend conducting pilot runs when switching substrates or adjusting film thickness. As manufacturers with hands-on experience across a wide range of pressing systems, we understand these details and are ready to provide support and recommendations tailored to your equipment and product setup.

With the right process control, soft touch PVC decorative film delivers unmatched tactile appeal and elegance, especially in premium furniture and cabinet applications. The velvety surface not only elevates the product’s aesthetic value but also enhances its perceived quality. If you're exploring ways to add more depth and comfort to your design surfaces, our soft touch solutions combine technical reliability with visual sophistication—perfect for brands looking to stand out with minimalistic yet impactful surface finishes.

English

English Español

Español عربى

عربى