Difference Between PET Decorative Film and PVC Decorative Film

2025-09-17

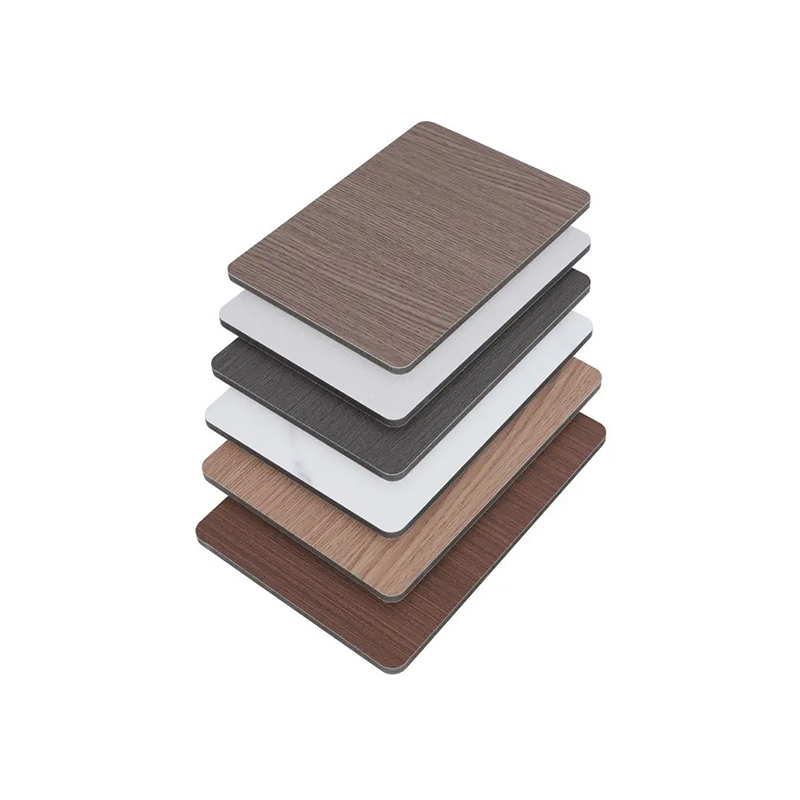

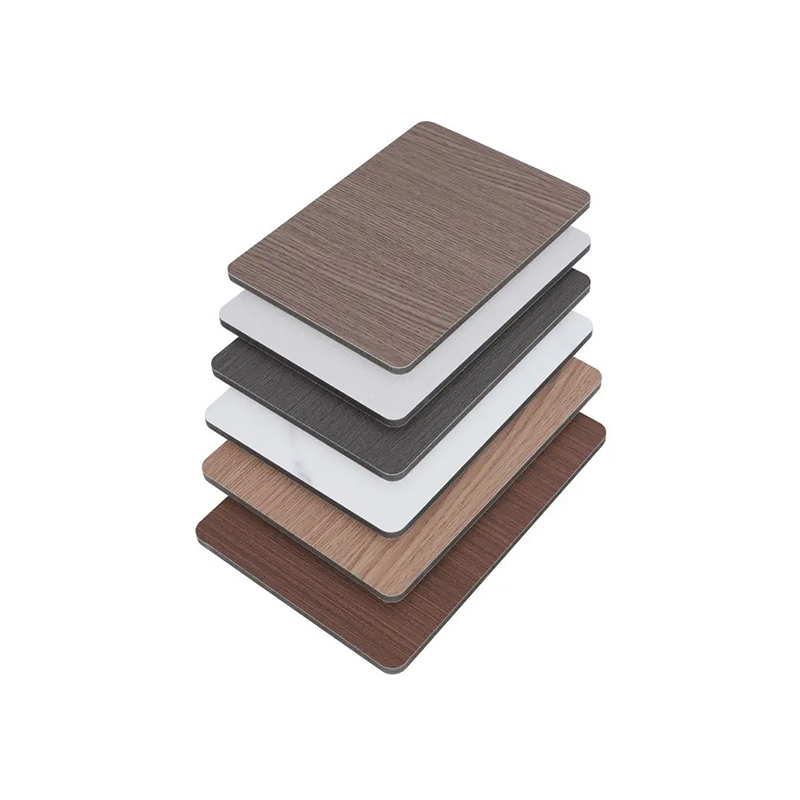

Decorative films are widely used in a variety of applications, including interior design, furniture, automotive, and electronics, to add aesthetic appeal while offering practical benefits like protection, durability, and UV resistance. PET (Polyethylene Terephthalate) and PVC (Polyvinyl Chloride) are two of the most common materials used to produce decorative films. Though both serve similar functions, there are significant differences in terms of material properties, performance, and environmental impact. Here’s a detailed breakdown of the differences between PET decorative film and PVC decorative film.

Content

1. Material Composition

-

PET (Polyethylene Terephthalate) Decorative Film:

- PET is a thermoplastic polymer that is a type of polyester. It is made through the polymerization of ethylene glycol and terephthalic acid. PET is a strong, durable, and transparent material.

- PET films are typically thinner, lighter, and more flexible compared to PVC films. PET films have high tensile strength and are often used in situations requiring a combination of strength and flexibility.

-

PVC (Polyvinyl Chloride) Decorative Film:

- PVC is a synthetic plastic polymer made from polymerizing vinyl chloride monomers. PVC films are made by stretching and processing PVC resin to create a flexible and durable film.

- PVC films tend to be thicker, heavier, and less flexible than PET films. They are also more rigid in comparison, which may influence their application in certain environments.

2. Durability and Strength

-

- PET films are generally known for their high tensile strength and resistance to deformation. They are resistant to tearing, scratching, and abrasions.

- UV Resistance: PET films have good resistance to ultraviolet (UV) light and do not yellow easily when exposed to sunlight. They are also resistant to moisture, making them suitable for outdoor applications.

- Chemical Resistance: PET is more chemically resistant compared to PVC. It can resist a wider range of chemicals without degradation.

-

PVC Decorative Film:

- PVC films, while durable, are not as strong or resistant to deformation as PET films. Over time, PVC can become brittle and prone to cracking, especially under UV exposure.

- UV Degradation: PVC tends to degrade when exposed to UV light for extended periods. This can cause discoloration (yellowing) and reduced strength, limiting its long-term use in outdoor applications unless treated with UV stabilizers.

- Chemical Resistance: PVC has lower chemical resistance than PET and can be degraded by certain acids, bases, or solvents.

3. Environmental Impact

-

PET Decorative Film:

- Recyclability: PET is widely regarded as an environmentally friendly material due to its high recyclability. PET films can be recycled and reused, making them a more sustainable choice in terms of waste management.

- Biodegradability: While PET is recyclable, it is not biodegradable. However, its recycling process reduces its environmental footprint when compared to PVC.

- Non-toxic: PET does not contain toxic substances like chlorine, which makes it safer for human health and the environment during both production and disposal.

-

PVC Decorative Film:

- Recyclability: PVC is technically recyclable, but it is more difficult to recycle compared to PET. The process often requires more energy and results in a lower-quality recycled material.

- Environmental Hazards: The production of PVC involves the use of chlorine and other chemicals, which can be harmful to the environment. When burned, PVC can release harmful dioxins, which are toxic to both humans and animals.

- Toxic Additives: PVC products may contain harmful additives such as plasticizers (e.g., phthalates) to improve flexibility, which can leach out over time and pose health risks. These additives also contribute to the environmental harm when the material is disposed of.

4. Aesthetic Properties

-

PET Decorative Film:

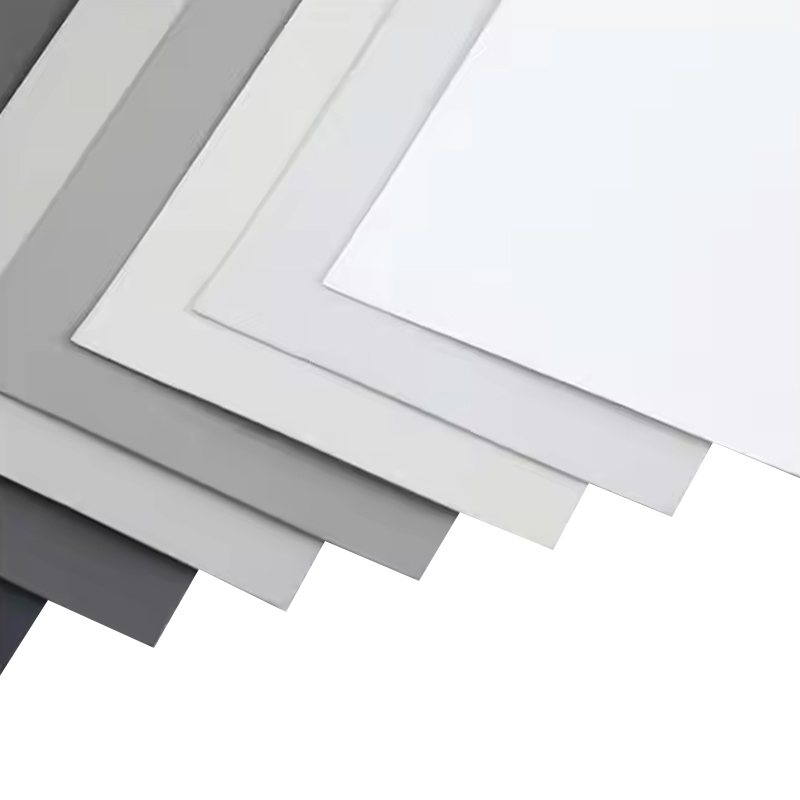

- PET decorative films are often more transparent than PVC films, allowing them to maintain clarity and brightness in designs.

- PET films can achieve high gloss, smooth textures, and clarity, making them suitable for high-end decorative applications.

- Due to its inherent strength and flexibility, PET films can be used for intricate designs and applications where thinness and smoothness are required.

-

PVC Decorative Film:

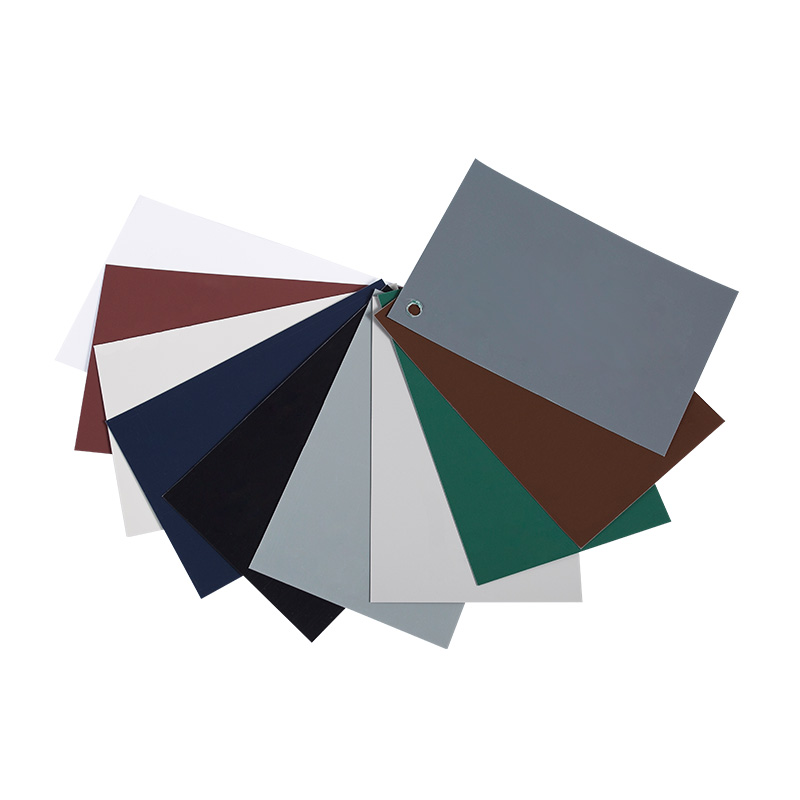

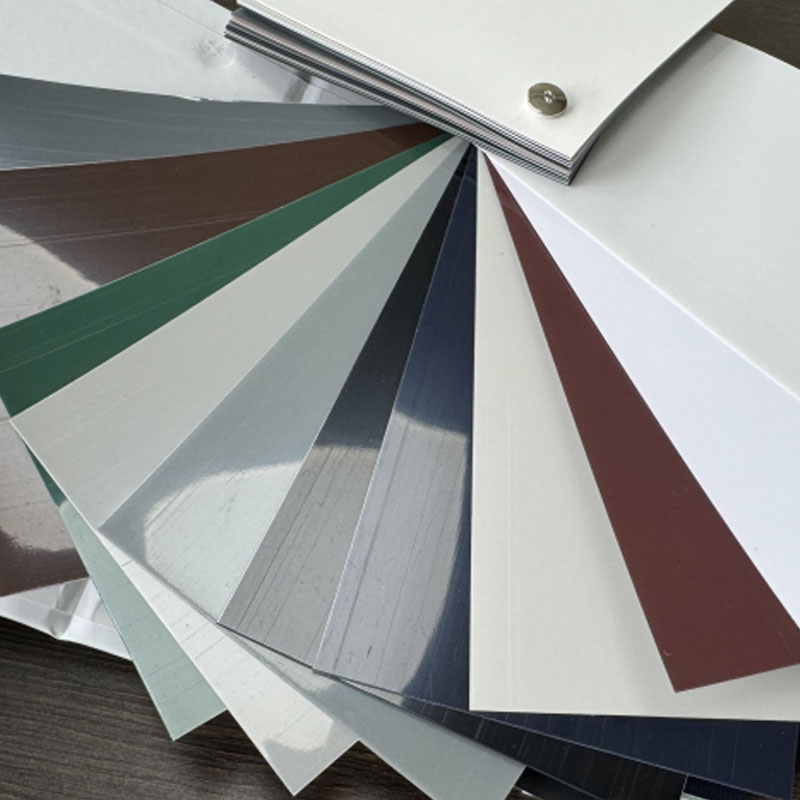

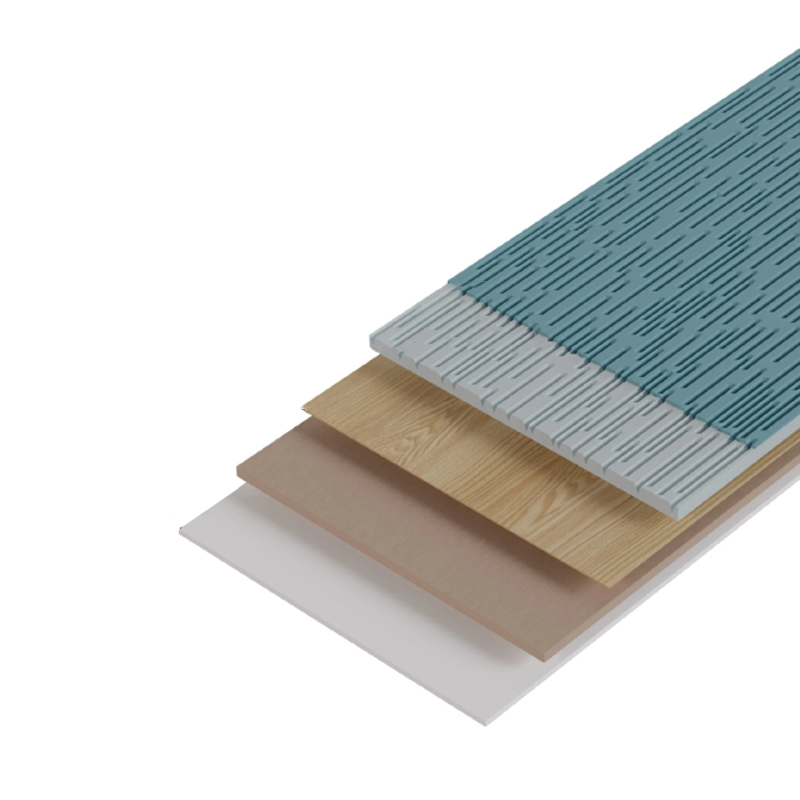

- PVC films offer a wide range of textures, including matte, glossy, and embossed finishes. PVC can also be easily printed or embossed with various decorative patterns.

- Color and Finish Variety: PVC films can be made in a wide variety of colors and finishes, making them highly customizable for specific aesthetic needs.

- However, because PVC films are generally thicker and more rigid, they might not offer the same smooth, high-quality finish that PET films provide, especially in applications where clarity is important.

5. Flexibility and Workability

-

PET Decorative Film:

- PET films are typically more flexible and lighter than PVC films. This makes them easier to apply to curved or irregular surfaces, which is particularly beneficial in applications like furniture wrapping, wall panels, or automotive interiors.

- PET is also more resistant to tearing and stretching compared to PVC, which makes it ideal for applications where the film needs to maintain its integrity under stress or tension.

-

PVC Decorative Film:

- PVC films are less flexible than PET and may require more effort or heat to manipulate during installation. However, this can be advantageous in certain applications where rigidity or a thicker, more durable finish is needed, such as for flooring or wall coverings.

- PVC films tend to be easier to print and emboss with intricate patterns due to their increased thickness and rigidity.

6. Applications

-

PET Decorative Film:

- Furniture and Interior Design: PET films are widely used for wrapping furniture, especially for their high gloss and clarity. They are also used for decorative wall panels, window films, and automotive interiors.

- Packaging: PET films are common in the packaging industry, especially for food packaging, as they are clear, non-toxic, and resistant to chemicals.

- Labels and Stickers: PET films are often used for high-end labeling applications, particularly where the print quality and visual clarity are critical.

- Electronics: PET is used for protective films and labels in the electronics industry due to its durability, scratch resistance, and clear finish.

-

PVC Decorative Film:

- Flooring and Wall Coverings: PVC films are often used in the flooring industry for creating vinyl tiles or laminate flooring. They are also popular in wall coverings and wallpaper due to their ability to resist moisture and durability.

- Automotive Interiors: PVC films are used for seat covers, dashboards, and other interior components, especially in the automotive industry, where flexibility and a variety of colors and textures are important.

- Signage and Banners: PVC films are widely used in outdoor signage and banners due to their flexibility, thickness, and ability to handle printing and embossing.

7. Cost Considerations

-

PET Decorative Film:

- Generally, PET films are more expensive than PVC films due to their higher manufacturing cost, better performance characteristics, and recyclability.

- However, the cost may be justified by the enhanced durability, aesthetic qualities, and environmental benefits.

-

PVC Decorative Film:

- PVC films are typically less expensive than PET films, making them a more economical choice for certain applications, particularly those that do not require high-end performance or long-term durability.

- The lower cost may also be due to the ease of manufacturing and the availability of a wide range of designs.

Conclusion

Both PET decorative films and PVC decorative films offer distinct advantages and disadvantages depending on the application. PET films excel in durability, chemical resistance, flexibility, and environmental friendliness (being recyclable and non-toxic), making them ideal for high-end, long-lasting, and eco-conscious applications. PVC films, on the other hand, provide affordability, a wide range of textures and finishes, and are suited for applications where rigidity, thickness, and flexibility are required.

When deciding between PET and PVC decorative films, it is important to consider factors such as:

- The environmental impact

- The performance requirements (e.g., durability, UV resistance)

- The application (e.g., furniture, automotive, signage)

- The budget

Choosing the right decorative film can enhance the aesthetics, performance, and longevity of your products.

Recommended Articles

-

1.1 What is PP Decorative Film? PP decorative film is a type of surface material made primarily from polypropylene, a versatile and widely used thermoplastic po...

View More -

Is your furniture looking tired, outdated, or damaged? Imagine transforming it effortlessly into something stunning, durable, and uniquely yours. Enter PVC deco...

View More -

1.Introduction Edge banding is a crucial finishing process used in woodworking and furniture manufacturing to cover and seal the exposed sides of materials such...

View More

English

English Español

Español عربى

عربى