Industries Where Solid Color PET Decorative Films Are Most Commonly Used

2025-09-22

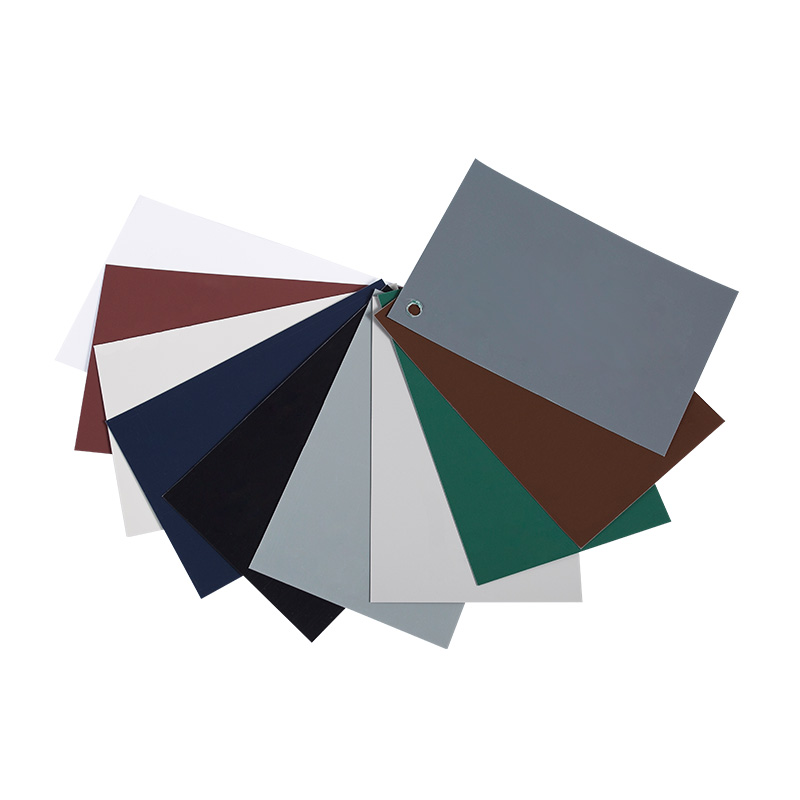

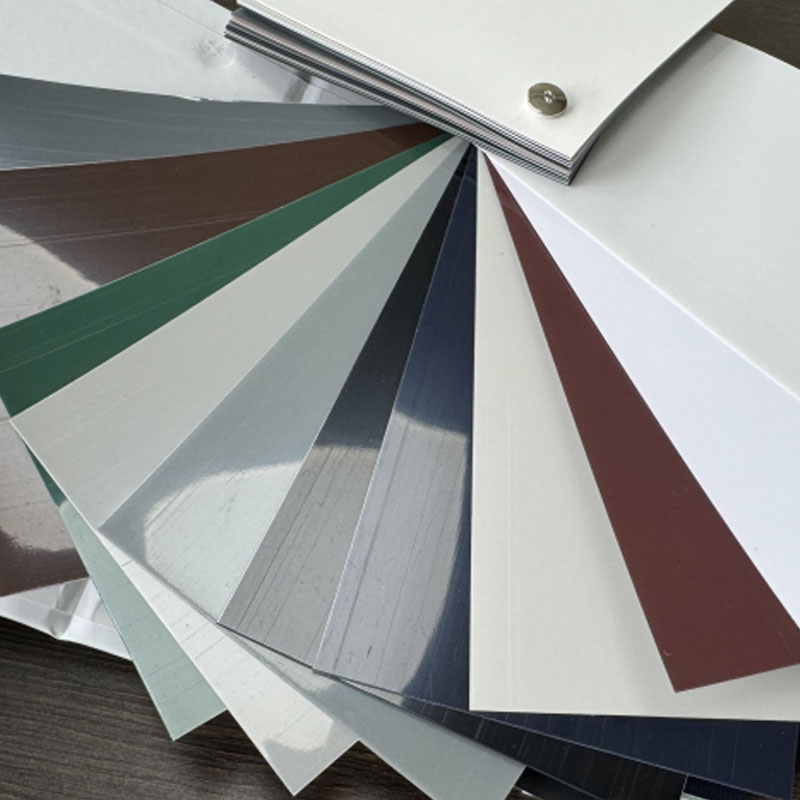

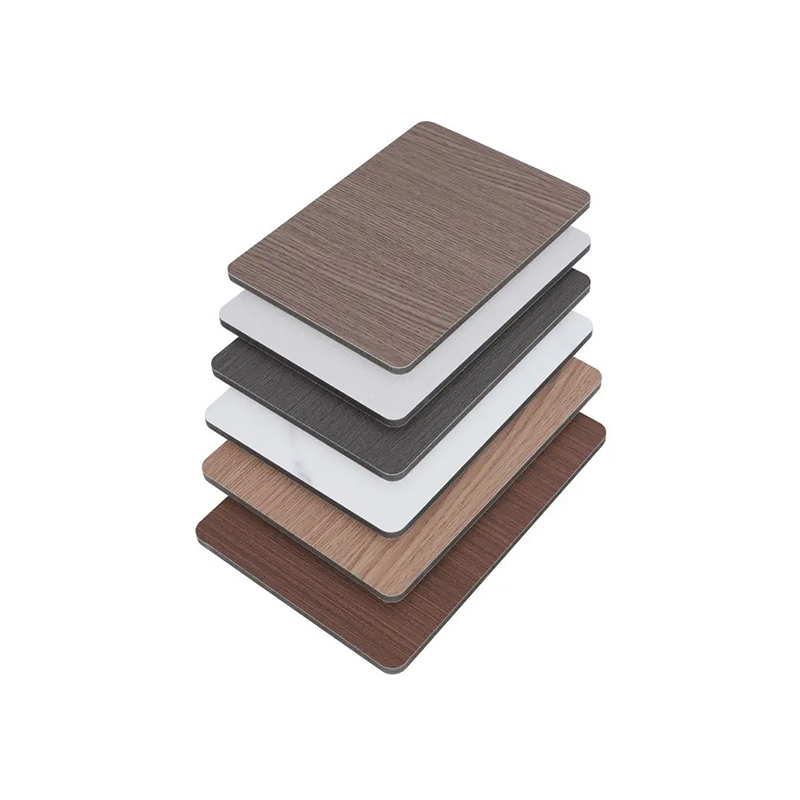

Solid color PET decorative films have become an essential material in modern manufacturing and design due to their versatility, durability, and aesthetic appeal. These films offer a combination of high mechanical strength, chemical resistance, heat stability, and uniform color, making them suitable for a wide range of applications across multiple industries. Below, we explore the main sectors where solid color PET decorative films are most commonly used and why they are preferred.

Content

1. Electronics and Consumer Devices

In the electronics industry, PET decorative films are widely applied to the exterior surfaces of smartphones, tablets, laptops, wearable devices, and other consumer electronics.

-

Applications: Device casings, overlay panels, protective covers, and decorative trims.

-

Advantages:

- Provides a sleek, uniform color finish that enhances product aesthetics.

- Offers scratch resistance and wear protection, helping maintain a premium appearance.

- Compatible with additional functional coatings, such as anti-fingerprint, anti-glare, or UV-resistant layers.

-

Example: Smartphones with glossy or matte colored backs, tablets with vibrant overlays, or laptops with colored trim panels.

The ability to customize color and finish makes PET films ideal for electronics manufacturers looking to differentiate products in a competitive market while maintaining functional performance.

2. Automotive Industry

The automotive sector increasingly uses solid color PET films for both interior and exterior applications due to their lightweight, durable, and visually appealing properties.

-

Applications: Dashboard panels, center consoles, door trims, decorative inlays, and exterior surface laminates.

-

Advantages:

- Withstands high temperatures, UV exposure, and daily wear without fading or cracking.

- Reduces vehicle weight compared to painted or metallic components.

- Allows for a wide range of finishes, including glossy, matte, or textured surfaces.

-

Example: Colored trim panels in luxury vehicles, matte-finished dashboards in passenger cars, or decorative inlays in EV interiors.

PET films also support cost-efficient production, as they eliminate the need for complex painting or coating processes while maintaining high-quality appearance standards.

3. Furniture and Interior Design

Furniture and interior design industries benefit from the aesthetic flexibility and durability of PET decorative films. They are widely used in residential, commercial, and office settings.

-

Applications: Laminates for kitchen cabinets, wardrobes, office desks, wall panels, decorative partitions, and shelving.

-

Advantages:

- Offers consistent, vibrant colors and a smooth finish.

- Resistant to scratches, cleaning agents, and daily wear.

- Lightweight and easy to install, reducing handling and shipping costs.

-

Example: Modular office furniture with matte-colored PET laminates, kitchen cabinets with glossy colored finishes, or decorative wall panels in commercial spaces.

By using PET films, designers and manufacturers can achieve premium visual effects without the high cost or environmental impact of traditional coatings or wood veneers.

4. Packaging Industry

PET decorative films are also utilized in the packaging sector, particularly for products requiring a visually striking appearance and protective surface.

-

Applications: Rigid or semi-rigid packaging, product sleeves, luxury boxes, and electronic or cosmetic packaging.

-

Advantages:

- Enhances product appearance with uniform, solid colors.

- Provides additional protection against scratches, moisture, and minor impacts.

- Can be laminated or combined with other materials for functional or aesthetic purposes.

-

Example: Luxury cosmetic packaging with glossy PET sleeves, electronics packaging with solid color overlays, or gift boxes with decorative PET films.

This combination of durability and design flexibility makes PET films ideal for brands aiming to create premium unboxing experiences.

5. Home Appliances and White Goods

PET films are increasingly used in appliances and home electronics to replace traditional painted or coated surfaces.

-

Applications: Refrigerator doors, microwave panels, washing machine exteriors, air purifiers, and kitchen appliances.

-

Advantages:

- Smooth, uniform surface that resists scratches and cleaning chemicals.

- Maintains color and finish over time, even under frequent use.

- Offers design flexibility with different colors, textures, and gloss levels.

-

Example: Colored refrigerator fronts with matte or glossy PET films, microwave oven doors with solid color panels, or washing machine lids with scratch-resistant PET overlays.

By applying PET films, manufacturers can reduce production costs while enhancing the durability and visual appeal of their products.

6. Signage, Advertising, and Displays

In commercial and public spaces, PET decorative films are used for signage and advertising due to their vibrant colors, smooth surface, and durability.

-

Applications: Trade show displays, retail signage, promotional panels, exhibition boards, and decorative branding elements.

-

Advantages:

- Provides consistent, solid color coverage that is visually striking.

- Resistant to abrasion, chemicals, and minor impacts, ensuring longevity in high-traffic areas.

- Lightweight and easy to cut, shape, or laminate for creative designs.

-

Example: Retail display panels with solid color PET films, trade show backdrops with vibrant finishes, or branded promotional boards for product launches.

The flexibility and performance of PET films make them ideal for both temporary and long-term display applications.

7. Emerging Applications

With technological advancements, PET decorative films are finding use in newer applications such as:

- Smart home devices: Colored overlays for IoT devices or control panels.

- Architectural facades: Decorative, lightweight panels with solid color finishes.

- Automotive EV interiors: Multi-layer PET laminates for dashboards and consoles that integrate functional coatings such as anti-scratch or anti-fingerprint layers.

These emerging applications demonstrate the ongoing versatility and growing demand for PET decorative films across industries.

Conclusion

Solid color PET decorative films are highly valued for their combination of durability, aesthetic versatility, and functional performance. They are most commonly used in:

- Electronics and consumer devices

- Automotive interiors

- Furniture and interior design

- Packaging for luxury or electronic products

- Home appliances and white goods

- Signage, advertising, and display panels

Their ability to maintain color stability, resist abrasion, and provide a premium visual finish makes them a preferred material wherever a high-quality, long-lasting colored surface is required. As industries continue to innovate, PET decorative films are likely to see even broader adoption in new applications, driven by demands for lightweight, durable, and visually appealing materials.

Recommended Articles

-

1.1 What is PP Decorative Film? PP decorative film is a type of surface material made primarily from polypropylene, a versatile and widely used thermoplastic po...

View More -

Is your furniture looking tired, outdated, or damaged? Imagine transforming it effortlessly into something stunning, durable, and uniquely yours. Enter PVC deco...

View More -

1.Introduction Edge banding is a crucial finishing process used in woodworking and furniture manufacturing to cover and seal the exposed sides of materials such...

View More

English

English Español

Español عربى

عربى