Solid Color PVC Edge Banding: A Sustainable Solution for Furniture Manufacturing

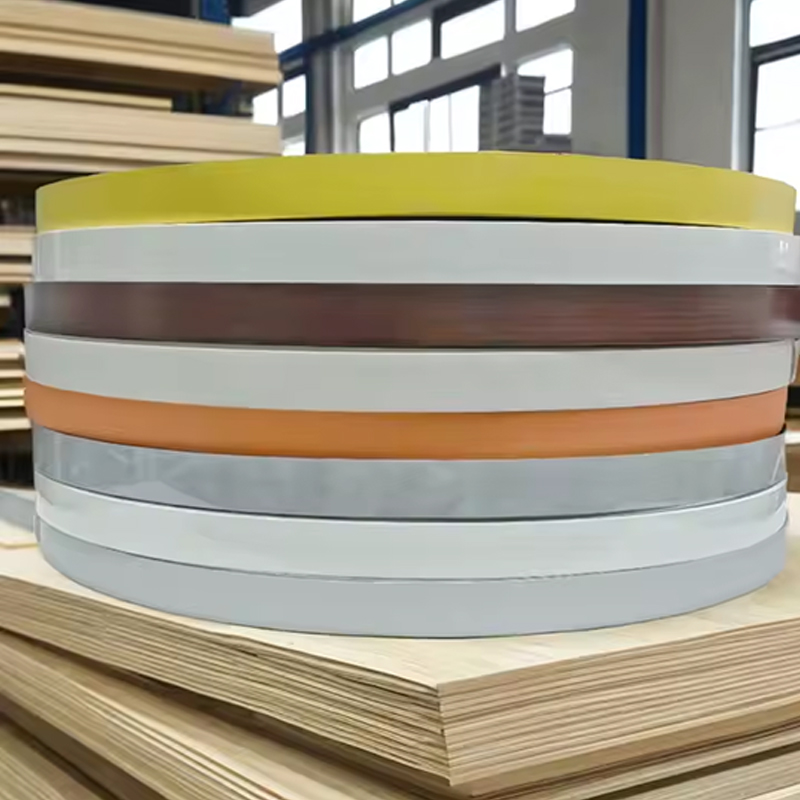

Solid color PVC edge banding has become an indispensable component in furniture production and interior decoration. This edge banding is crafted from polyvinyl chloride (PVC) through extrusion molding combined with advanced surface treatments, resulting in a material that balances strength, flexibility, and aesthetic versatility. With thickness options ranging from 0.35mm to 1.2mm and widths from 12mm to 60mm, it adapts well to various furniture panel sizes and design requirements, making it suitable for cabinetry, customized furniture edges, and interior decorative trims.

Environmental Compliance as a Foundation for Sustainability

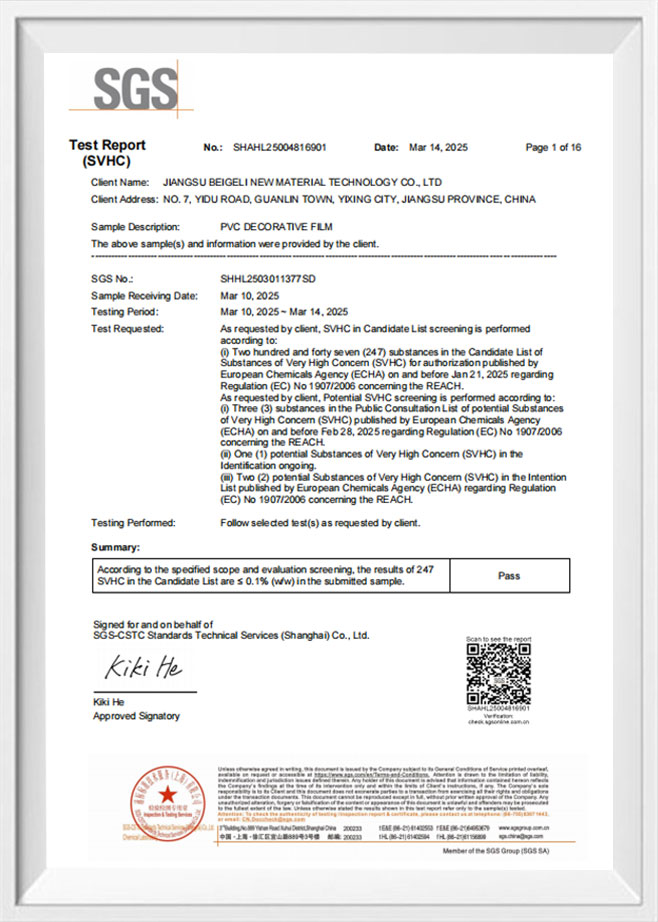

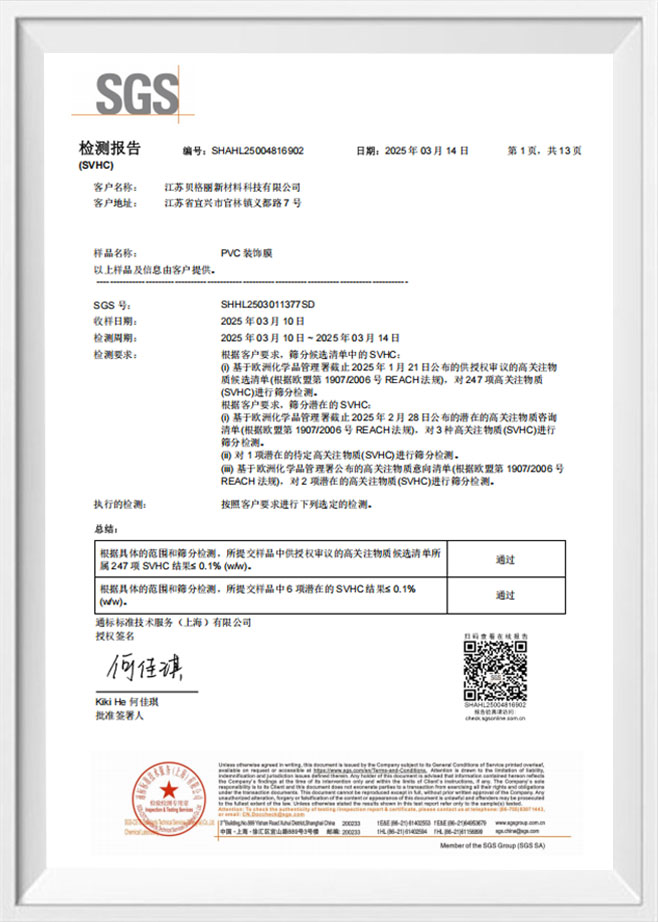

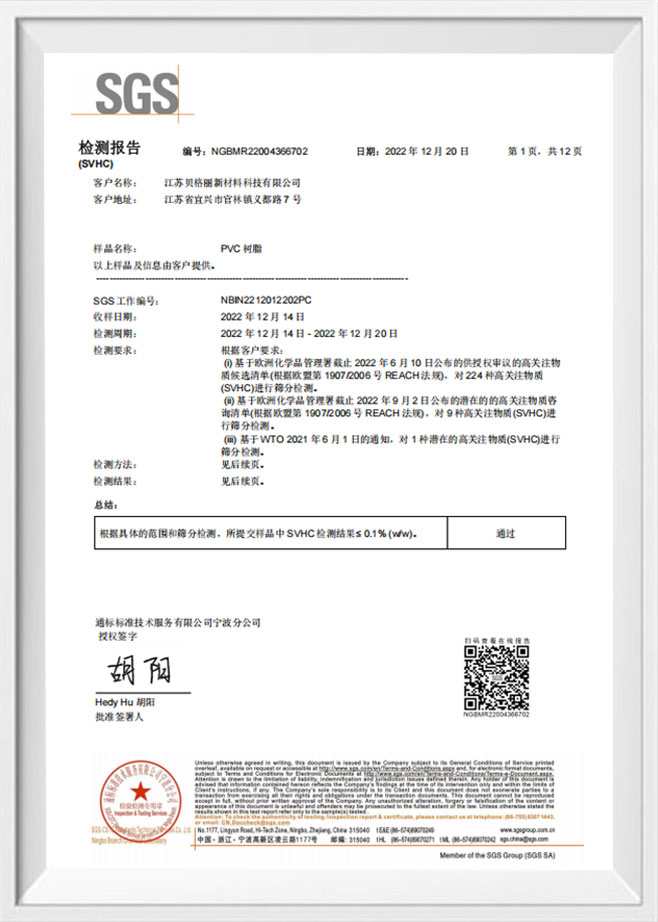

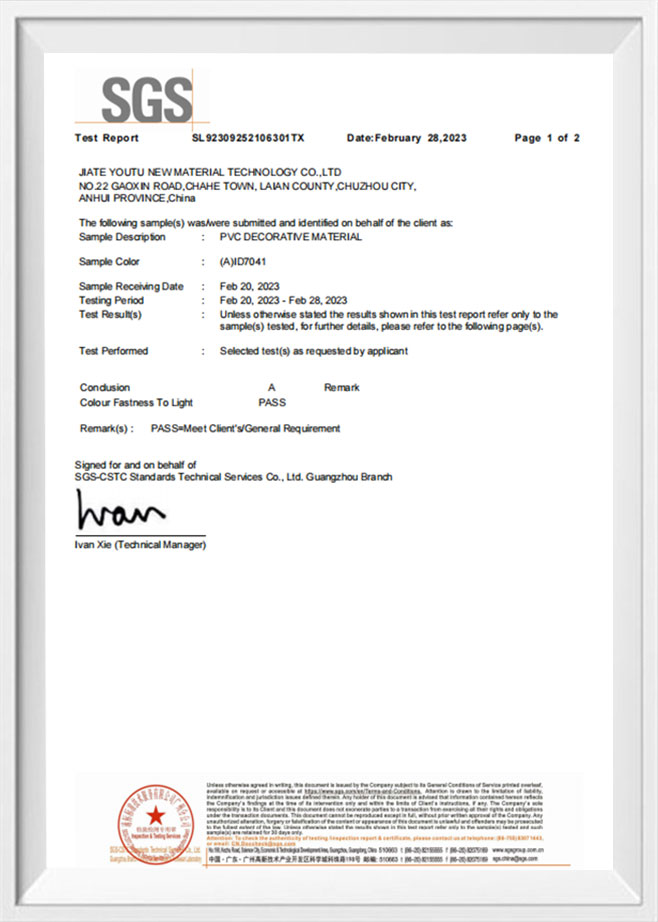

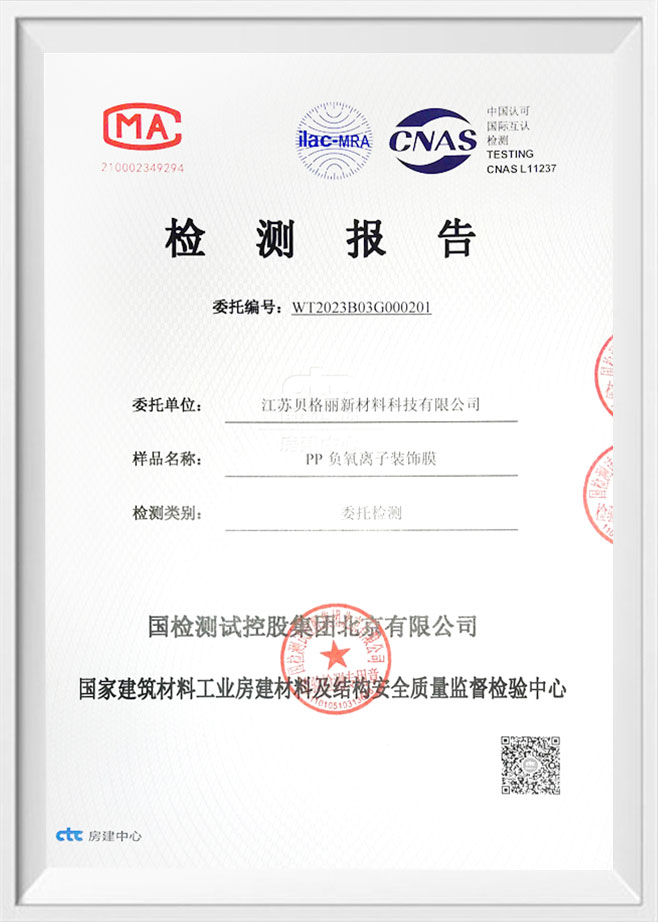

One of the defining features of modern solid color PVC edge banding is its alignment with critical environmental standards such as RoHS and REACH. These regulations limit hazardous substances and require manufacturers to monitor and reduce environmental impacts throughout the product lifecycle. By complying with these standards, the PVC edge banding used in furniture manufacturing reduces potential risks to human health and the environment.

For manufacturers, this means selecting materials that support sustainable production practices without sacrificing performance or appearance. Using RoHS and REACH-compliant edge banding helps furniture makers meet increasingly strict regulatory requirements and consumer demand for greener products. The result is furniture that not only looks refined but is also safer and more environmentally responsible.

Jiaxing Xuanyi’s Integrated Production System: Ensuring Quality and Cost Efficiency

Jiaxing Xuanyi International Trade Co., Ltd. has established a comprehensive supply chain that covers every stage from raw material sourcing to calendaring and coating. This vertically integrated model is a core strength that enables precise control over quality and costs. With its own raw material factory, calender factory, and coating factory, Jiaxing Xuanyi avoids reliance on external suppliers, reducing production uncertainties and enhancing product consistency.

Such control over the manufacturing process ensures that every batch of solid color PVC edge banding meets rigorous quality standards. Advanced inspection and measurement tools, combined with a strict international quality management system, guarantee that the edge banding performs well in wear resistance, flexibility, and chemical stability. This level of reliability is crucial for furniture manufacturers aiming to deliver long-lasting products.

Versatile Applications and Design Options

The versatility of solid color PVC edge banding extends to both its practical applications and aesthetic possibilities. It is widely used for edge finishing in furniture panels, kitchen cabinets, and various interior decorative elements. Its flexibility allows it to conform to straight or curved edges smoothly, preventing cracking or peeling even after long-term use.

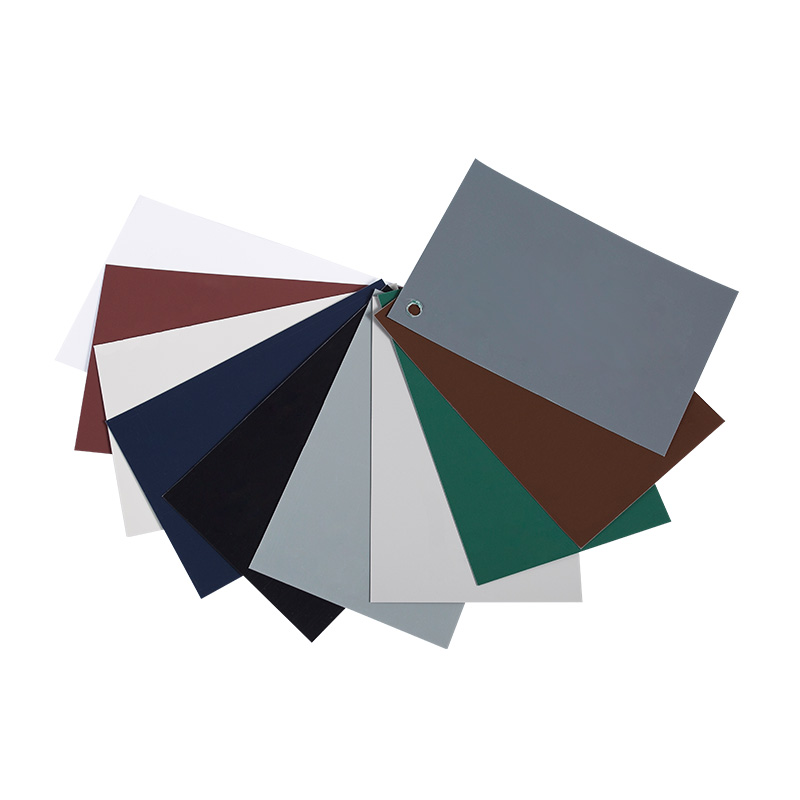

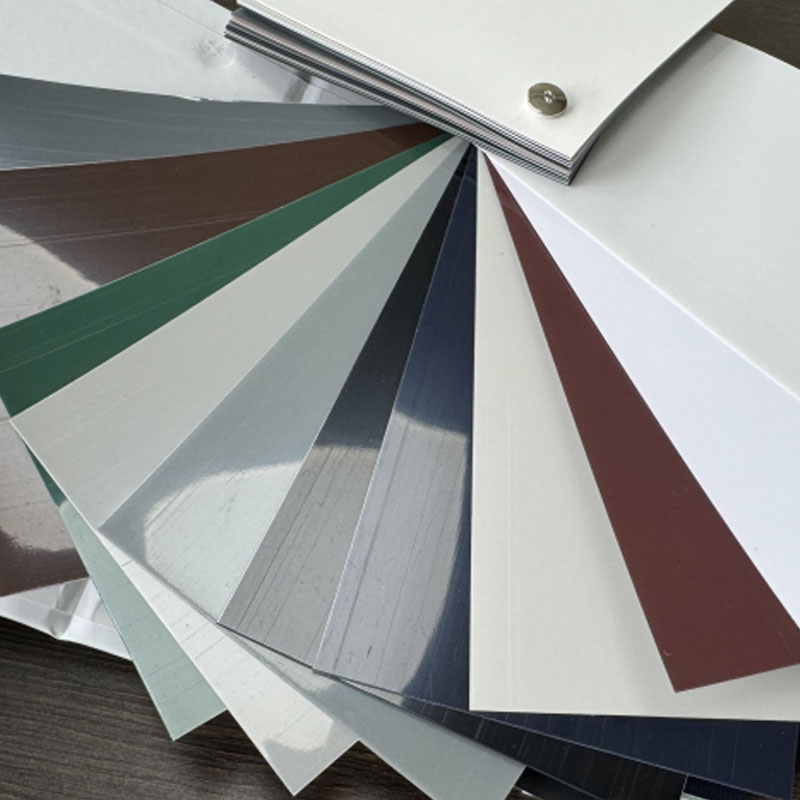

Designers and manufacturers appreciate the wide variety of available colors and finishes. Whether opting for matte or high-gloss surfaces, solid color PVC edge banding can complement different furniture styles and interior themes. This range of choices helps create cohesive designs that meet both functional and visual expectations.

Furthermore, the edge banding is compatible with various production techniques, including vacuum pressing, flat lamination, and profile wrapping. This compatibility ensures efficient integration into existing manufacturing workflows without additional complexity or cost.

Continuous Innovation Driven by Professionalism

Beyond product quality and environmental compliance, Jiaxing Xuanyi maintains a strong focus on innovation. Guided by principles such as professionalism, quality, cooperation, and win-win collaboration, the company continuously explores new technologies and materials. This dedication has led to the development of advanced product series featuring anti-scratch coatings and soft-touch textures, enriching the tactile and protective qualities of PVC edge banding.

These innovations not only improve user experience but also expand the material’s applications, meeting the evolving demands of global furniture markets. Jiaxing Xuanyi’s commitment to technological progress ensures its products remain competitive and aligned with industry trends toward sustainability and enhanced performance.

Conclusion

Solid color PVC edge banding offers a comprehensive solution that meets modern furniture manufacturing needs by combining durability, design flexibility, and environmental responsibility. Its compliance with RoHS and REACH regulations underscores its role as a sustainable material choice, while Jiaxing Xuanyi’s integrated production and quality assurance systems guarantee reliability and competitive pricing.

For furniture producers and interior designers seeking materials that contribute to sustainable manufacturing and long-lasting aesthetics, solid color PVC edge banding from a manufacturer like Jiaxing Xuanyi stands out as a practical and forward-looking option.

English

English Español

Español عربى

عربى