Understanding Thickness and Width Variations in Wood Grain PVC Edge Banding

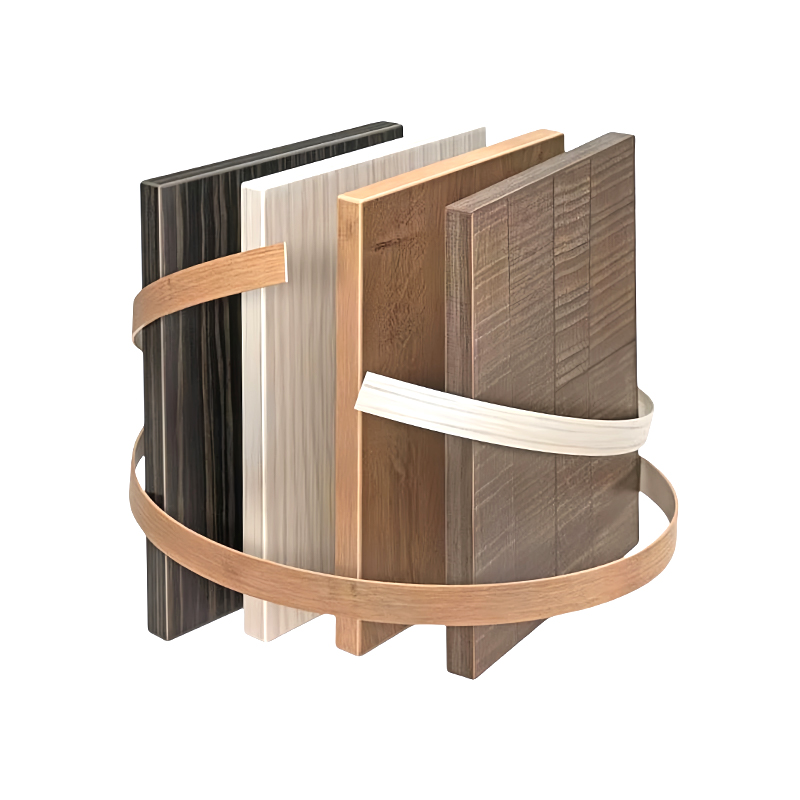

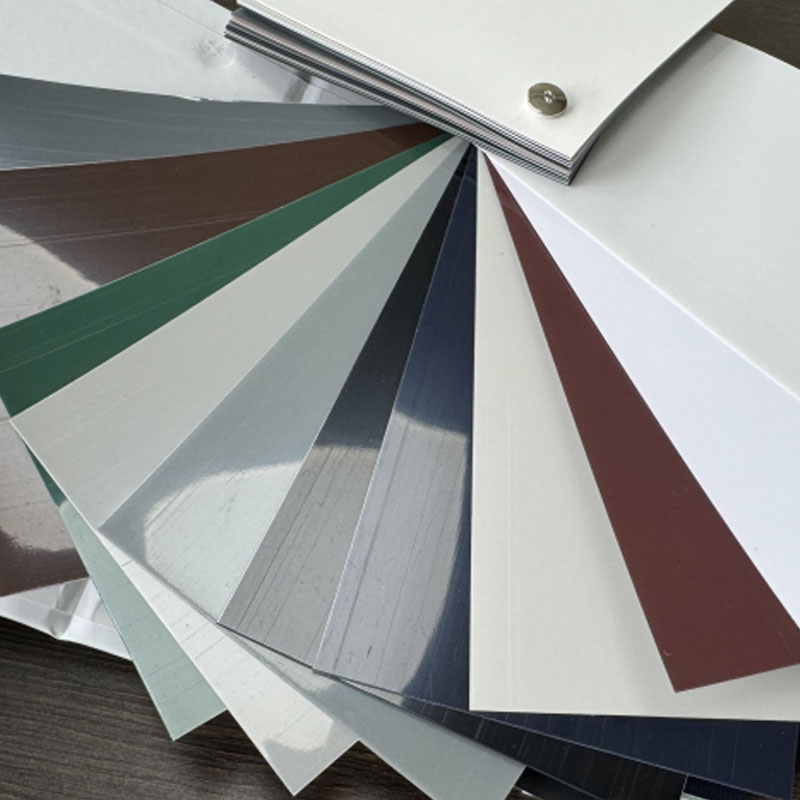

Wood grain PVC edge banding plays a crucial role in furniture production and interior finishing. Designed to replicate the natural look and texture of wood, it provides an aesthetic and functional edge treatment for panels, cabinetry, and other surfaces. Among the most important considerations for selecting the right edge banding are its thickness and width—two dimensions that directly influence application, appearance, and performance.

Why Thickness Matters in PVC Edge Banding

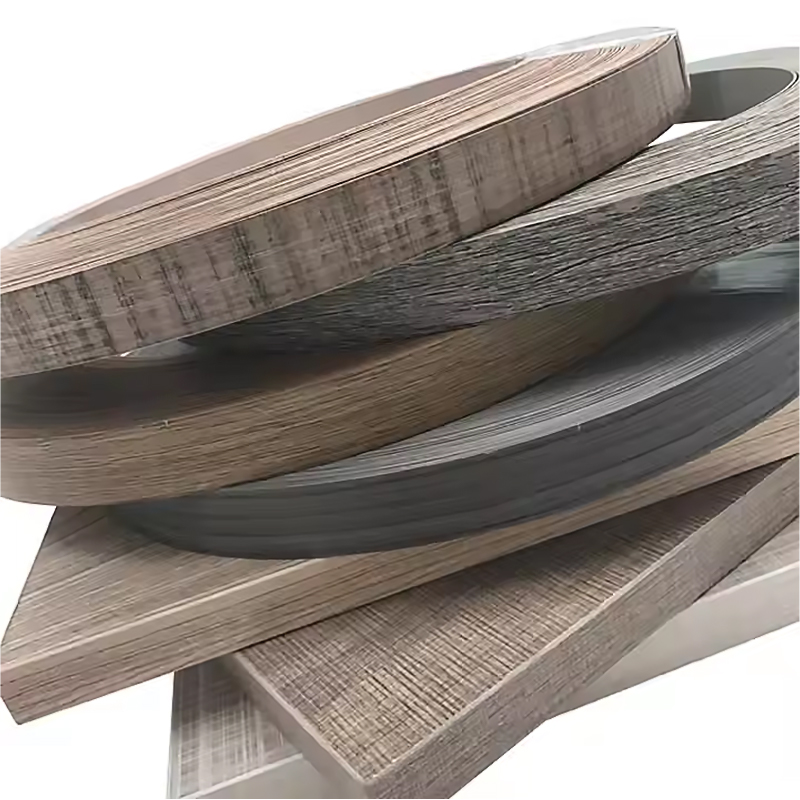

The thickness of wood grain PVC edge banding typically ranges from 0.35mm to 1.2mm. Thinner variants are often preferred for simple, flat-edged panels or for applications where flexibility is required. They are easy to apply, cost-effective, and work well in less demanding environments. On the other hand, thicker edge banding offers increased durability and impact resistance, making it more suitable for high-traffic areas or furniture expected to endure frequent use, such as office desks, wardrobes, and kitchen cabinetry.

A well-chosen thickness also affects how seamlessly the edge banding blends with the main panel. In modern furniture, a visually cohesive finish is critical. Whether opting for a subtle outline or a more prominent, protected edge, manufacturers and designers can tailor the outcome by adjusting the thickness accordingly.

The Functionality of Width in Edge Banding Design

Edge banding widths generally range from 12mm to 60mm, offering ample versatility for various panel sizes and edge styles. Narrow widths are typically used for standard shelving or small-format boards, while wider options are reserved for thicker panels or more complex edge shapes. Choosing the correct width not only ensures complete coverage of the panel edge but also enhances bonding and visual uniformity.

The width should also correspond with the edge banding application method—whether using manual edge banders or fully automated systems—since mismatched sizes can lead to inefficient production or even material waste. That’s why manufacturers often provide multiple sizing options to suit different processing needs and end-use scenarios.

The Role of Production Technology

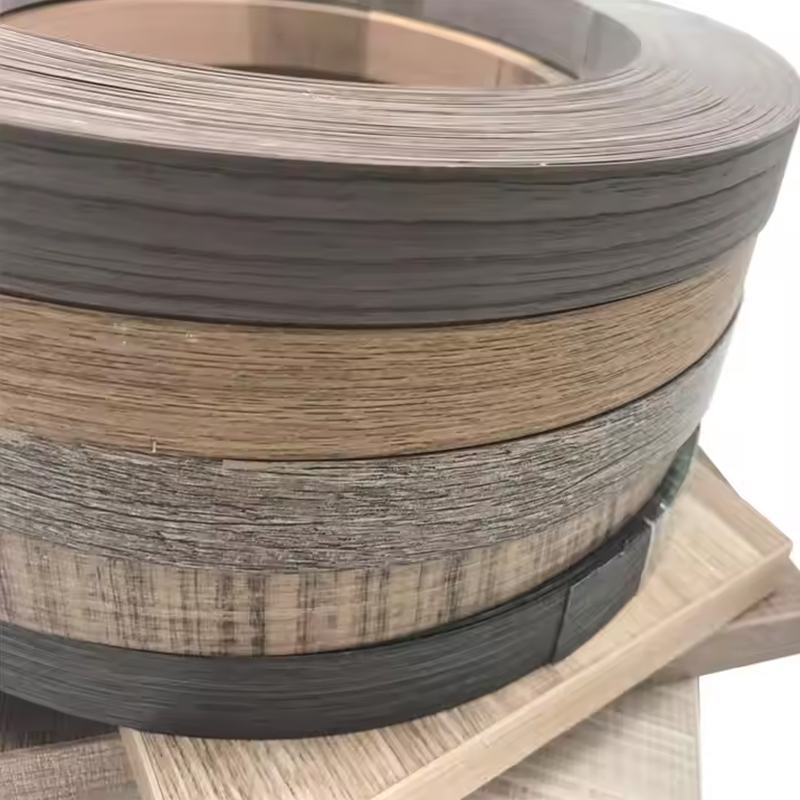

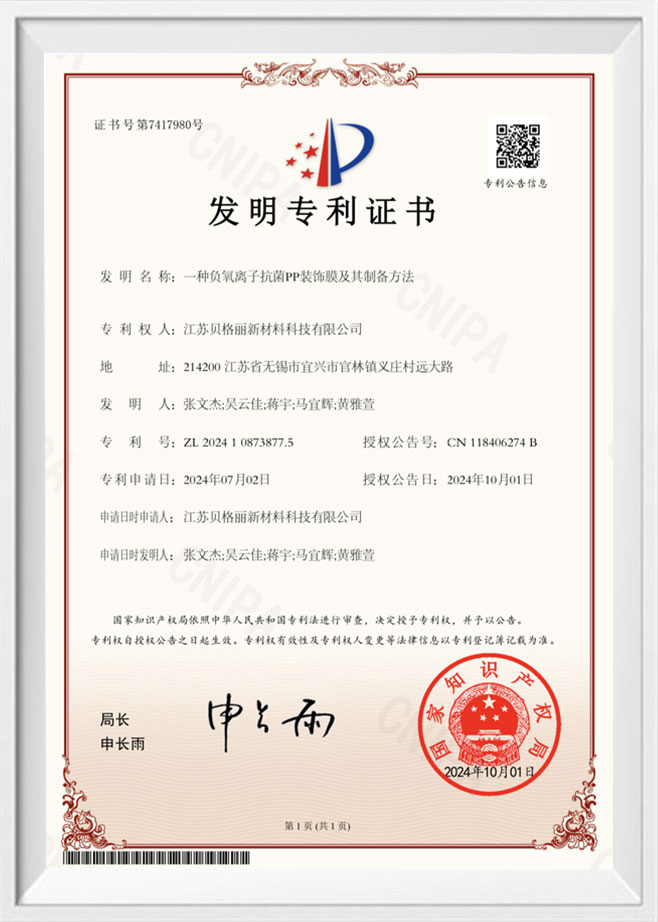

The ability to offer such precise variations in thickness and width stems from a combination of advanced production techniques. In particular, wood grain PVC edge banding is manufactured using gravure printing or thermal transfer to achieve realistic wood patterns, followed by extrusion molding to maintain consistent dimensional integrity.

Behind these manufacturing processes are companies like Jiaxing Xuanyi International Trade Co., Ltd, which integrates raw material production, calendaring, and coating into one cohesive supply chain. This vertically integrated setup allows for enhanced control over dimensions, quality consistency, and customization capabilities—all while maintaining cost competitiveness.

Meeting Application Needs Across Industries

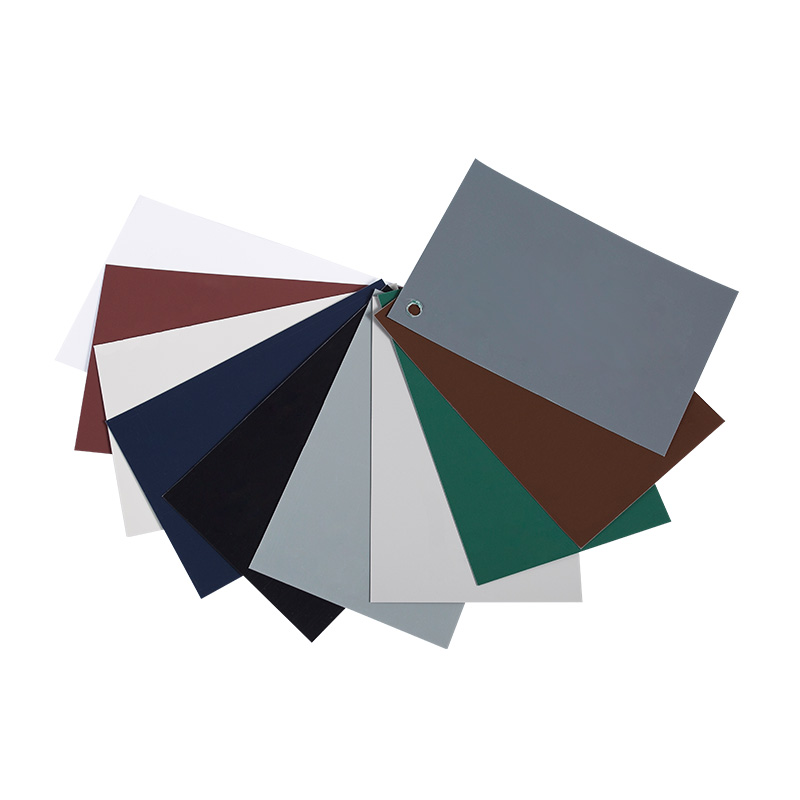

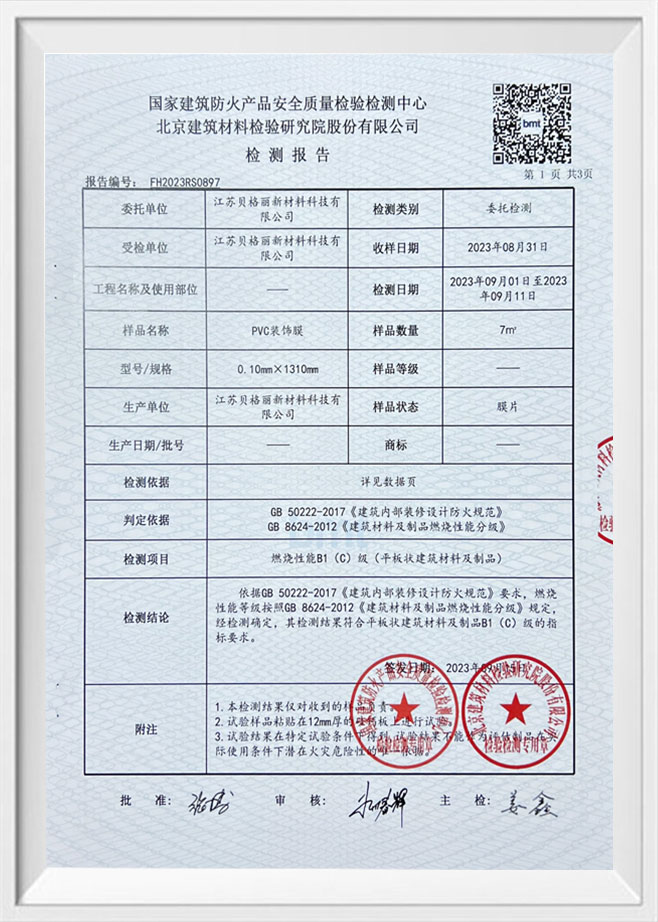

Edge banding with varied thickness and width options is not just a matter of design flexibility; it’s also about meeting the demands of multiple industries. Whether used in home furniture, commercial interiors, or custom-built cabinetry, wood grain PVC edge banding must be able to perform under different conditions. Attributes like wear resistance and weather durability—achieved through careful material formulation and precise sizing—further expand its application potential.

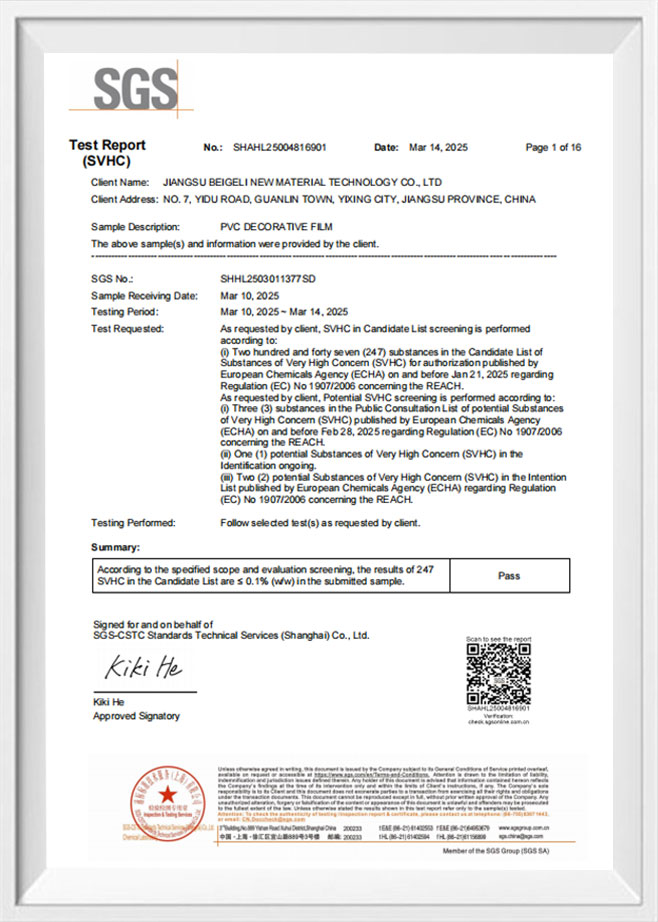

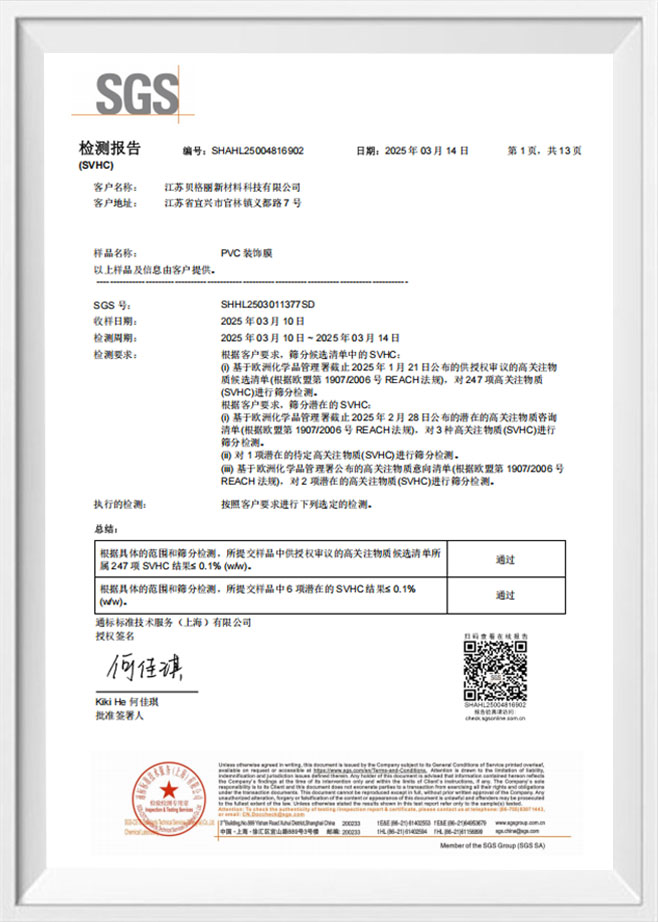

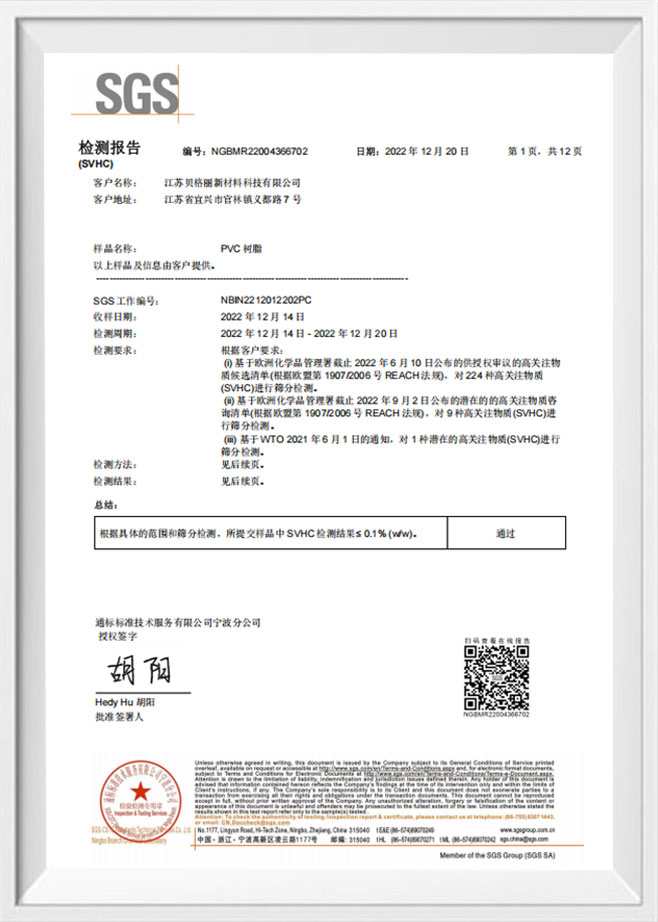

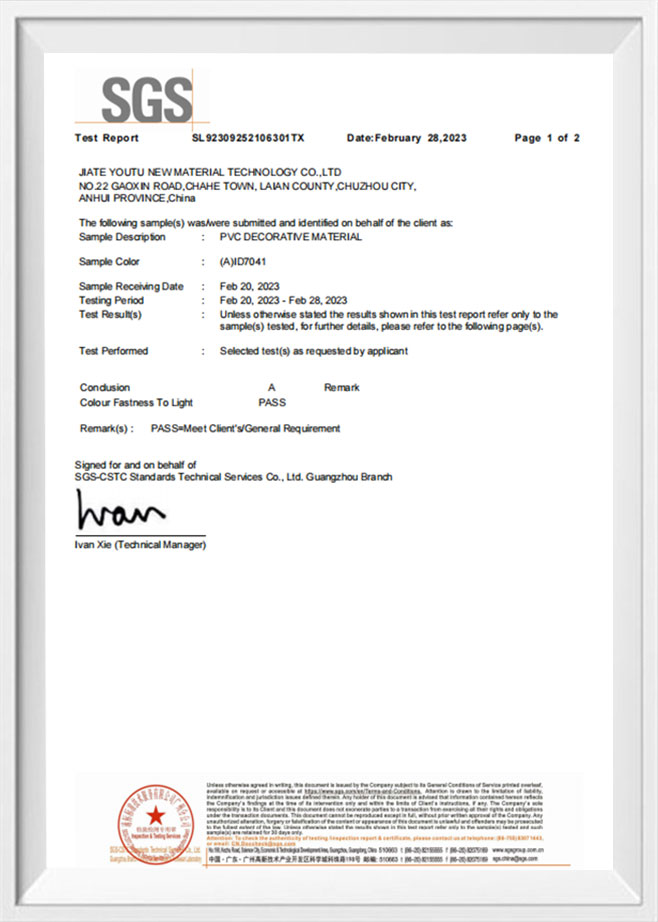

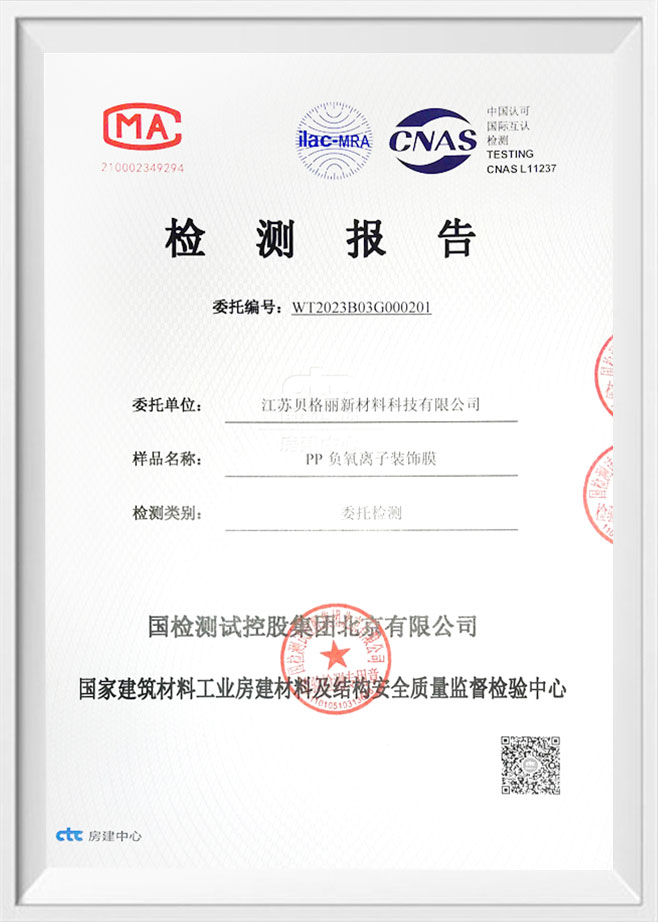

With manufacturers increasingly looking for RoHS and REACH-compliant materials, dimensional versatility also has to come with environmental responsibility. This dual focus on performance and compliance ensures that edge banding can support both current design needs and evolving regulatory standards.

Expertise and Quality Assurance

Companies like Jiaxing Xuanyi emphasize rigorous quality management across all stages of production. From the choice of PVC formulations to the calibration of printing and cutting machinery, every detail contributes to maintaining accurate sizing. Their dedication to precision reflects in their edge banding products’ performance across global markets, making them a reliable choice for customers seeking consistency, durability, and aesthetic appeal.

English

English Español

Español عربى

عربى