PETG Decorative Film: Versatile and Durable Surfaces for Modern Design

2026-01-29

Content

- 1 PETG Decorative Film: The Versatile Surface Solution for Modern Design

- 2 What is PETG Decorative Film? Composition and Properties

- 3 Primary Applications and Industries

- 4 Comparing PETG Film to Alternative Materials

- 5 Selection Guide: Choosing the Right PETG Film for Your Project

- 6 Lamination and Fabrication Best Practices

PETG Decorative Film: The Versatile Surface Solution for Modern Design

PETG decorative film is a high-performance thermoplastic film rapidly transforming interior design, retail displays, and product manufacturing. Made from Polyethylene Terephthalate Glycol (PETG), this material offers an exceptional balance of aesthetics, durability, and functionality. Unlike traditional vinyl or PVC films, PETG film provides superior clarity, toughness, and environmental credentials, making it the go-to choice for architects, fabricators, and designers seeking to combine visual appeal with practical performance.

What is PETG Decorative Film? Composition and Properties

PETG film is produced from a copolymer where glycol is added during the polymerization of PET (common plastic used in bottles). This modification eliminates brittleness, resulting in a material that is exceptionally clear, strong, and easy to thermoform. Decorative PETG films are often finished with custom prints, textures, metallic effects, or solid colors on one side, with an adhesive or non-adhesive backing. Key material properties include:

- High Impact Strength: Significantly more shatter-resistant than acrylic or standard polystyrene, making it safe for high-traffic areas.

- Excellent Clarity and Gloss: Offers near-glass-like transparency for displays or can be produced in vibrant, opaque colors with a consistent finish.

- Chemical and Stain Resistance: Resists degradation from many household cleaners, alcohols, and oils, ensuring long-term aesthetics.

- Ease of Fabrication: Can be easily die-cut, CNC routed, and, most notably, thermoformed into complex 3D shapes without losing the printed image or whitening (excellent deep-draw capabilities).

- Food Safety and Recyclability: Many grades are FDA-compliant for food contact, and PETG is widely recyclable (Resin ID #1), aligning with sustainable design goals.

Primary Applications and Industries

PETG decorative film's versatility allows it to be applied to various substrates, creating cost-effective and stunning surfaces. Its primary applications span multiple industries:

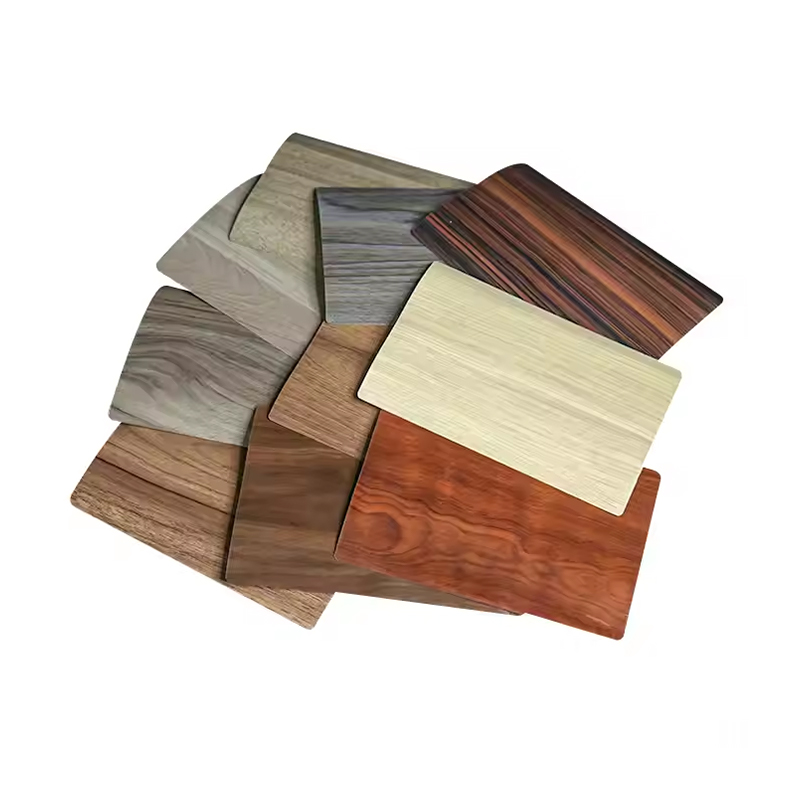

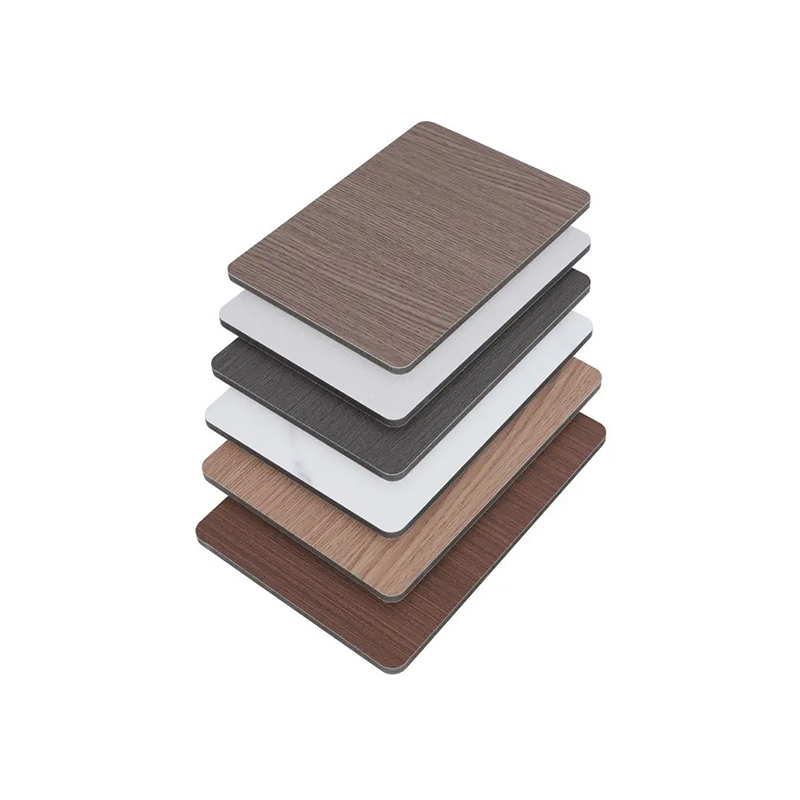

Retail and Interior Design

Used to create eye-catching feature walls, column covers, and decorative panels in stores, hotels, and offices. It can mimic expensive materials like wood, stone, or brushed metal at a fraction of the cost and weight. Its durability makes it ideal for POS displays, kiosks, and shelving liners.

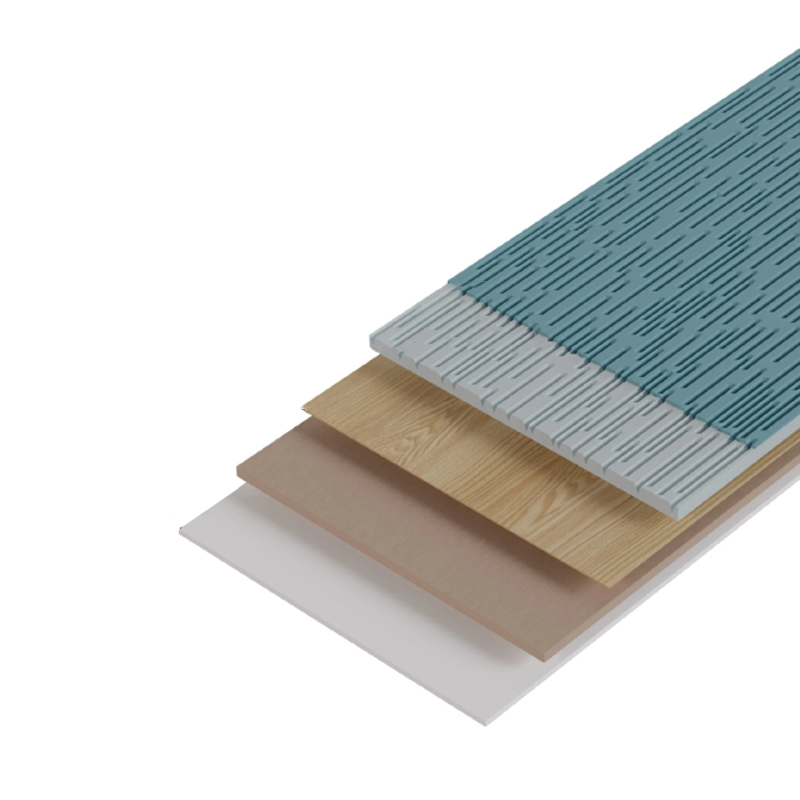

Appliance and Furniture Manufacturing

Applied to medium-density fibreboard (MDF), particleboard, or metal via lamination to create finished surfaces for refrigerator cabinets, dishwasher panels, office furniture, and kitchen cabinetry. This provides a seamless, easy-to-clean alternative to traditional paint or powder coating.

Transportation and Automotive Interiors

Employed for interior trim components in RVs, buses, trains, and cars. Its ability to thermoform over complex curves allows for stylish, durable dashboards, door panels, and console covers that resist UV fading and wear.

Signage and Visual Communication

Widely used for backlit signs, menu boards, and decorative letters. Its clarity makes it perfect for light diffusion, while its printability allows for high-resolution graphics that are protected by the film's surface.

Comparing PETG Film to Alternative Materials

Selecting the right decorative laminate requires understanding material trade-offs. The table below highlights how PETG film compares to common alternatives like PVC and acrylic films.

| Property | PETG Film | PVC Film | Acrylic (PMMA) Film |

|---|---|---|---|

| Impact Resistance | Excellent | Good | Poor (Brittle) |

| Thermoformability | Excellent (Low Forming Temp) | Good | Fair (Requires Higher Temp) |

| Clarity/Gloss | Very High | Good | Highest |

| Chemical Resistance | Very Good | Good | Excellent |

| Environmental Profile | Recyclable, No Chlorines | Contains Chlorine, Recycling Complex | Recyclable |

Selection Guide: Choosing the Right PETG Film for Your Project

Not all PETG films are identical. Making the correct choice involves specifying several key parameters based on the application's demands:

- Thickness: Ranges from 0.05mm to over 1.0mm. Thinner films (0.1-0.3mm) are ideal for flat laminations and cost-sensitive projects, while thicker films (0.5mm+) provide more depth and rigidity for 3D forming and heavy-use surfaces.

- Adhesive Type: Options include permanent pressure-sensitive adhesive (PSA), removable PSA, or non-adhesive (for use with separate laminating glue). For curved surfaces, a high-tack, thermoformable adhesive is essential.

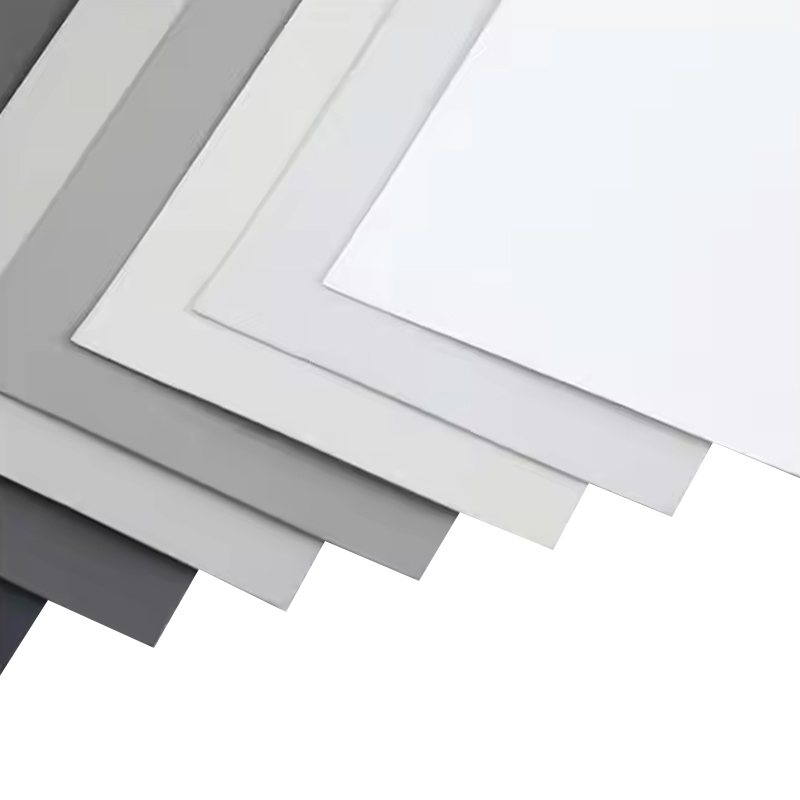

- Surface Finish: Choose from high-gloss, matte, satin, or textured finishes (e.g., leather, linen). Textured finishes can help hide minor substrate imperfections and reduce fingerprints.

- Print Technology: Ensure the film is compatible with the intended printing method (e.g., UV inkjet, solvent inkjet, screen printing) and has appropriate coatings to ensure ink adhesion and scratch resistance.

- Performance Additives: For outdoor or window applications, specify films with UV stabilizers to prevent fading and yellowing. Anti-fog or anti-static coatings are also available for specialized needs.

Lamination and Fabrication Best Practices

Successful application of PETG film depends on proper technique. Following these steps ensures a bubble-free, durable finish:

- Substrate Preparation: The substrate (MDF, acrylic, metal, etc.) must be perfectly clean, dry, and smooth. Sand MDF to a minimum 180-grit finish and seal edges to prevent adhesive absorption. Wipe with isopropyl alcohol to remove dust.

- Film Conditioning: Allow the film roll to acclimate to the room temperature (typically 18-25°C) for 24 hours before unwrapping to prevent thermal shrinkage or expansion during application.

- Lamination Process: For flat surfaces, use a cold laminating roller system or a vacuum membrane press. Start from one edge and gradually smooth the film onto the substrate, using a squeegee to eliminate air pockets. For pressure-sensitive films, apply consistent, firm pressure.

- Thermoforming: For 3D shapes, the laminated substrate is heated in an oven until the PETG film becomes pliable (typically 130-150°C). It is then quickly transferred to a mold and formed using vacuum pressure, ensuring even stretching without webbing or tearing.

- Trimming and Finishing: Once cooled, excess film is trimmed using a sharp router bit or knife. For best results, use CNC routing for precise cuts on complex shapes.

PETG decorative film stands as a testament to material innovation, offering designers a tool that bridges the gap between ambitious aesthetics and real-world durability. Its role in enabling cost-effective, sustainable, and visually striking surfaces ensures its continued growth across design and manufacturing industries.

Recommended Articles

-

1.1 What is PP Decorative Film? PP decorative film is a type of surface material made primarily from polypropylene, a versatile and widely used thermoplastic po...

View More -

Is your furniture looking tired, outdated, or damaged? Imagine transforming it effortlessly into something stunning, durable, and uniquely yours. Enter PVC deco...

View More -

1.Introduction Edge banding is a crucial finishing process used in woodworking and furniture manufacturing to cover and seal the exposed sides of materials such...

View More

English

English Español

Español عربى

عربى