Performance Features to Consider When Selecting PVC Decorative Film

2026-01-21

Content

- 1 Material Structure and Film Composition

- 2 Surface Durability and Wear Resistance

- 3 Heat Resistance and Dimensional Stability

- 4 Adhesion Performance During Application

- 5 Visual Consistency and Decorative Effect

- 6 Moisture and Chemical Resistance

- 7 Ease of Processing and Production Efficiency

- 8 Long-Term Performance in End-Use Environments

Material Structure and Film Composition

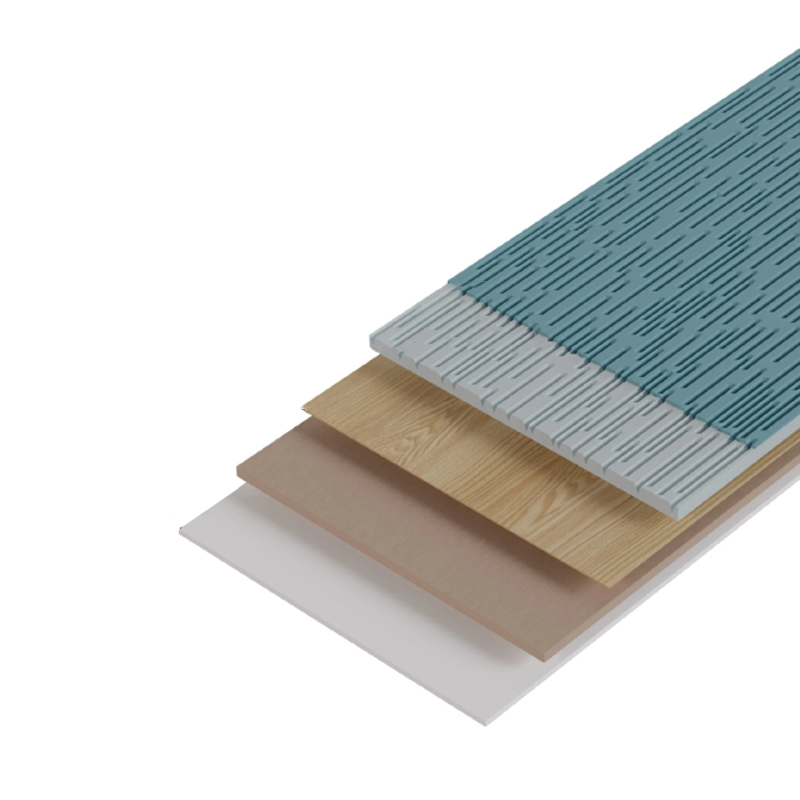

When selecting PVC decorative film, the internal structure and material composition play a direct role in overall performance. PVC decorative films are typically composed of multiple layers, including a base PVC layer, a printed or embossed decorative layer, and a protective surface coating. The balance between flexibility and rigidity determines how well the film performs during lamination, wrapping, or flat pressing processes. A stable structure helps reduce deformation during heat application and contributes to consistent surface quality across large panels or complex profiles.

Surface Durability and Wear Resistance

Surface durability is a key consideration, especially for applications such as furniture panels, cabinet doors, and wall coverings that experience frequent contact. PVC decorative film with enhanced wear resistance maintains its appearance under repeated use and cleaning. The surface coating influences scratch resistance, abrasion tolerance, and resistance to surface whitening over time. These characteristics are particularly relevant in commercial interiors and high-traffic residential spaces.

Impact of Protective Coatings

Protective coatings applied to PVC decorative film surfaces help shield the printed layer from mechanical damage and environmental exposure. Different coating formulations affect gloss level, tactile feel, and long-term performance. A well-designed coating layer can reduce visible wear while preserving color clarity and texture definition.

Heat Resistance and Dimensional Stability

Heat resistance is critical for PVC decorative films used in thermoforming, membrane pressing, or profile wrapping. Films with stable thermal behavior retain their dimensions and surface appearance when exposed to elevated temperatures during processing. Dimensional stability also helps prevent edge lifting, shrinking, or surface distortion after installation, contributing to consistent product quality.

Adhesion Performance During Application

Adhesion performance affects how reliably PVC decorative film bonds to substrates such as MDF, particleboard, plywood, or composite panels. Good adhesion supports smooth surfaces without bubbling or peeling, even around edges and corners. Film back-side treatment and compatibility with common adhesives influence bonding consistency across different production methods.

- Stable bonding on flat and profiled surfaces

- Reduced risk of delamination over time

- Compatibility with common hot melt and PUR adhesives

Visual Consistency and Decorative Effect

Visual consistency is essential for decorative applications where multiple panels or components must match in appearance. PVC decorative film should offer stable color reproduction, uniform gloss levels, and consistent pattern alignment across production batches. These factors are especially important for wood grain, stone texture, and solid color designs used in furniture and interior fittings.

Moisture and Chemical Resistance

PVC decorative film is often selected for environments where moisture exposure or routine cleaning is expected. Resistance to humidity, mild chemicals, and household cleaning agents helps preserve surface quality over time. This performance feature supports use in kitchens, bathrooms, retail spaces, and hospitality interiors.

Ease of Processing and Production Efficiency

From a manufacturing perspective, ease of processing directly impacts efficiency and yield. PVC decorative films that feed smoothly through laminating equipment and respond predictably to heat and pressure help reduce setup time and material waste. Stable processing behavior also contributes to consistent output quality in large-scale production.

| Performance Feature | Practical Benefit |

| Dimensional stability | Reduces deformation during processing |

| Surface durability | Maintains appearance under daily use |

| Adhesion performance | Supports reliable bonding to substrates |

Long-Term Performance in End-Use Environments

Evaluating long-term performance helps ensure that PVC decorative film continues to meet functional and visual requirements throughout its service life. Factors such as resistance to fading, surface wear, and environmental exposure influence how well the film performs after installation. Selecting a film with balanced performance features supports stable results in both residential and commercial applications.

Recommended Articles

-

1.1 What is PP Decorative Film? PP decorative film is a type of surface material made primarily from polypropylene, a versatile and widely used thermoplastic po...

View More -

Is your furniture looking tired, outdated, or damaged? Imagine transforming it effortlessly into something stunning, durable, and uniquely yours. Enter PVC deco...

View More -

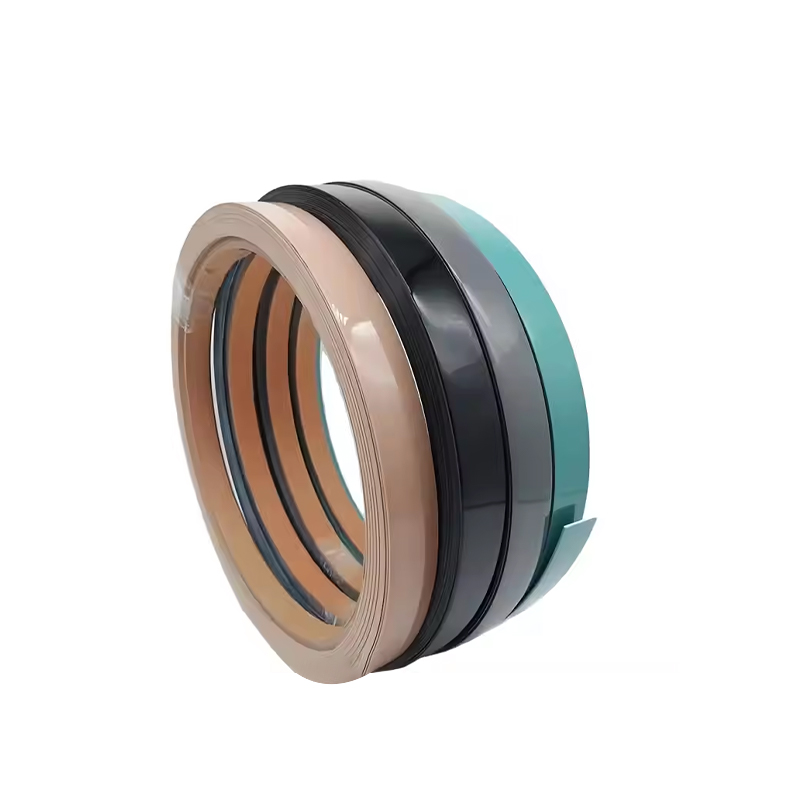

1.Introduction Edge banding is a crucial finishing process used in woodworking and furniture manufacturing to cover and seal the exposed sides of materials such...

View More

English

English Español

Español عربى

عربى