Why Furniture Manufacturers Prefer ABS Edge Banding in Solid Colors

In the competitive world of furniture production, where both aesthetics and performance matter, edge banding materials have a significant impact on the final product’s appearance, durability, and quality. Among the various options available, solid color ABS edge banding has become a preferred choice for many furniture manufacturers. Its functional properties, design flexibility, and environmental advantages make it particularly suitable for modern manufacturing needs.

A Practical Choice for Durable and Stylish Finishes

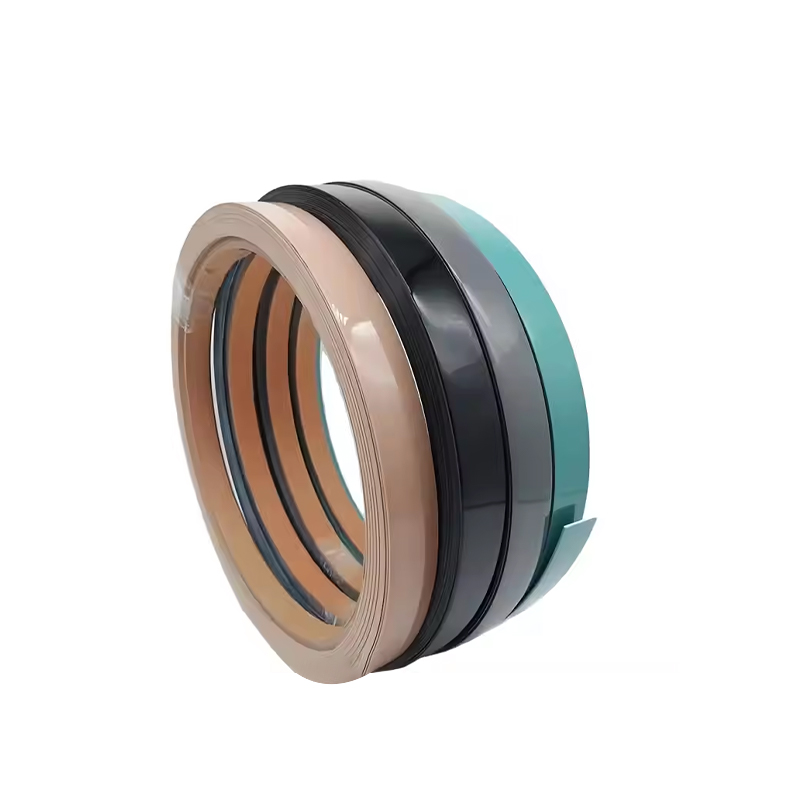

Solid color ABS (Acrylonitrile Butadiene Styrene) edge banding offers a sleek and uniform look that complements a wide range of furniture designs. Known for its excellent impact resistance and wear durability, ABS edge banding withstands the daily stress furniture faces in residential and commercial environments. This is especially important in applications such as kitchen cabinetry, wardrobes, and office furniture, where sharp corners and frequent use can quickly wear down lower-quality materials.

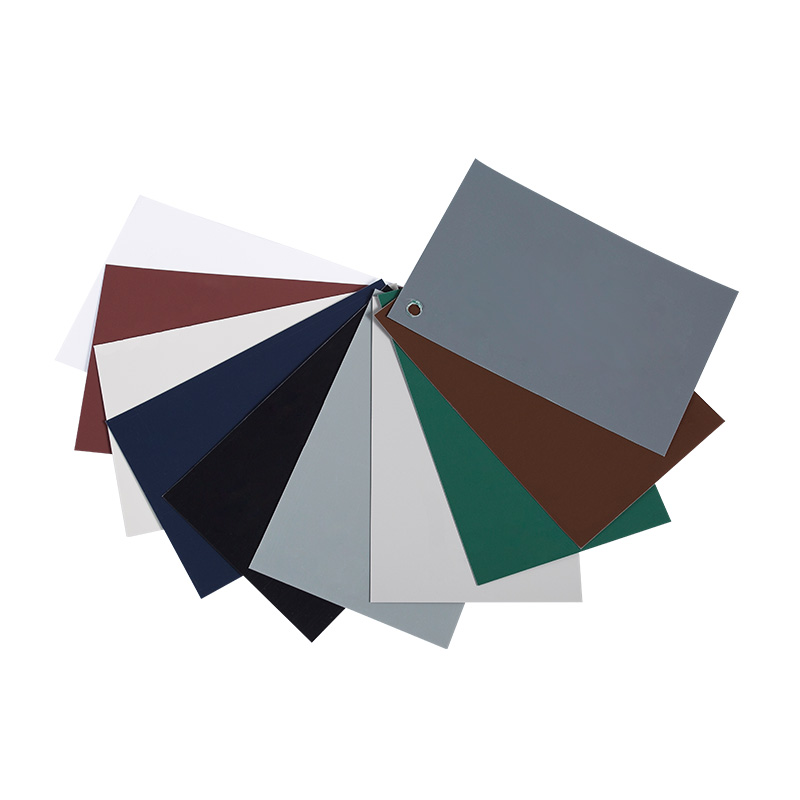

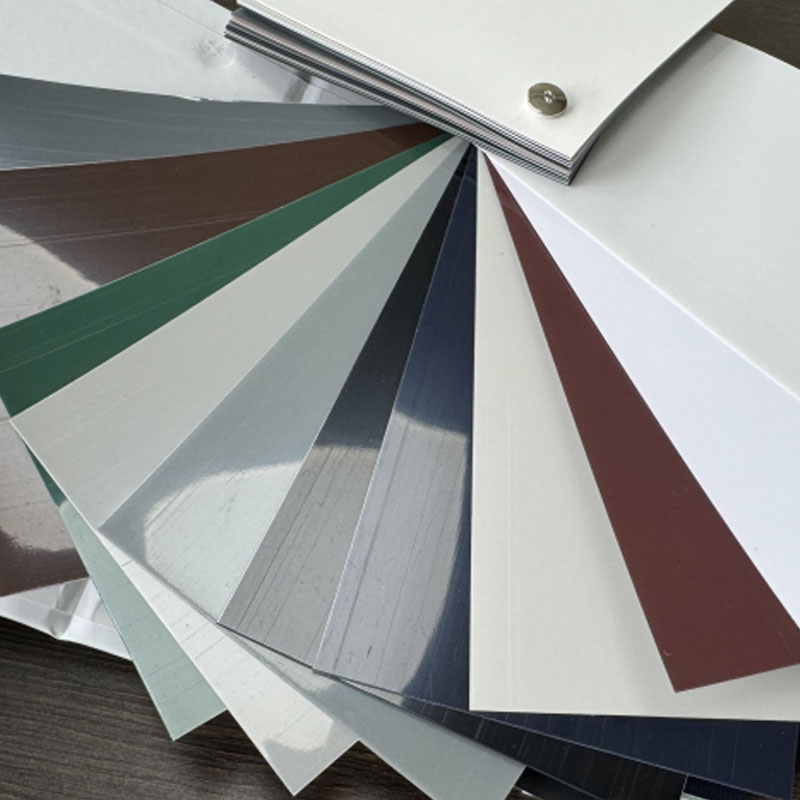

The surface of ABS edge banding is typically smooth and easy to clean, with no visible seams when applied properly. The availability of matte and high-gloss finishes in solid colors helps designers match the banding to laminated or painted surfaces, creating a seamless visual transition along the panel edges.

Customizable Dimensions for Flexible Application

Furniture manufacturers value flexibility in material dimensions to accommodate different product specifications. Solid color ABS edge banding is available in thicknesses ranging from 0.6mm to 1.2mm and widths between 12mm and 60mm. This range supports a variety of applications, from thin shelving to thicker cabinet panels. Manufacturers also benefit from customization options that allow edge banding to be tailored precisely to their production lines and design intentions.

This level of versatility reduces waste and increases production efficiency, especially for companies that deal with multiple furniture styles or require fast design adjustments to meet market demand.

A Trusted Supply Chain and Technical Expertise

Behind the growing popularity of ABS edge banding are companies that ensure consistent quality and reliable delivery. Jiaxing Xuanyi International Trade Co., Ltd., located in Zhejiang province, plays a key role in supporting furniture manufacturers worldwide. With a vertically integrated operation—including raw material production, calendaring, and coating—Jiaxing Xuanyi maintains control over each stage of manufacturing, allowing for better cost management and faster response to customer needs.

By owning its supply chain, the company can deliver edge banding that meets specific dimensional and performance requirements while maintaining competitive pricing. This is particularly valuable for large-scale furniture producers who rely on consistent supply and quality assurance.

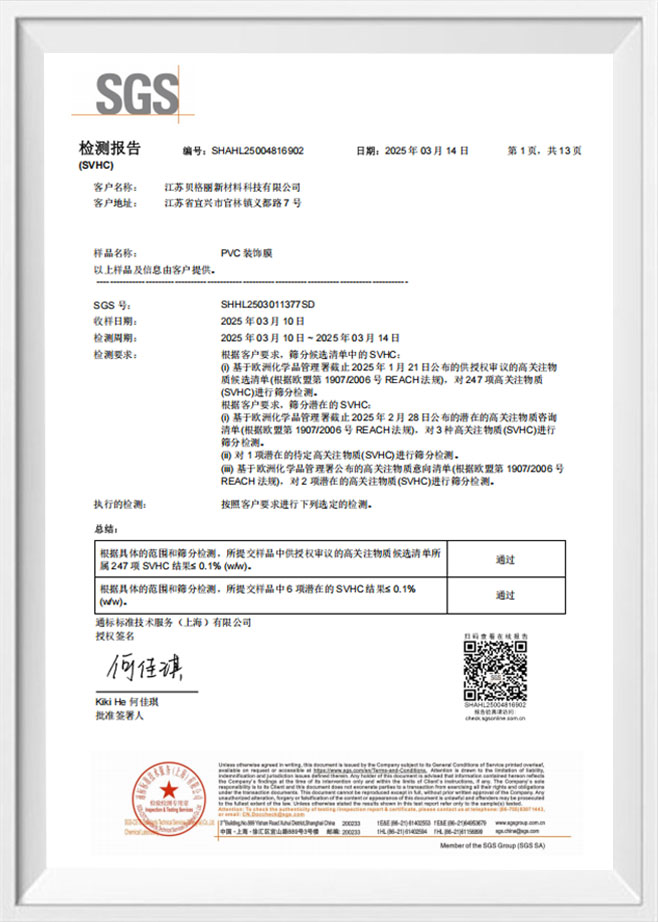

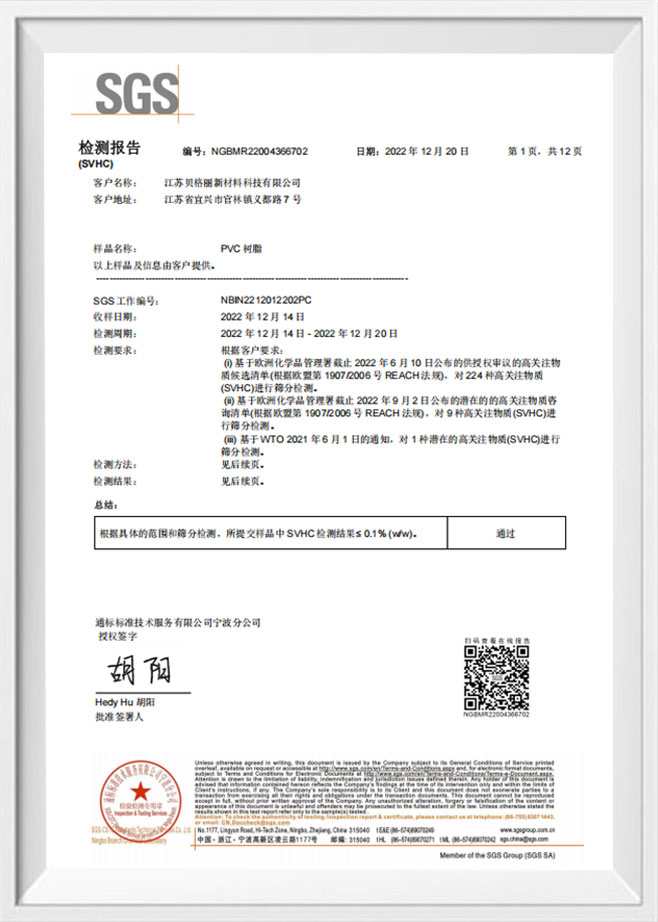

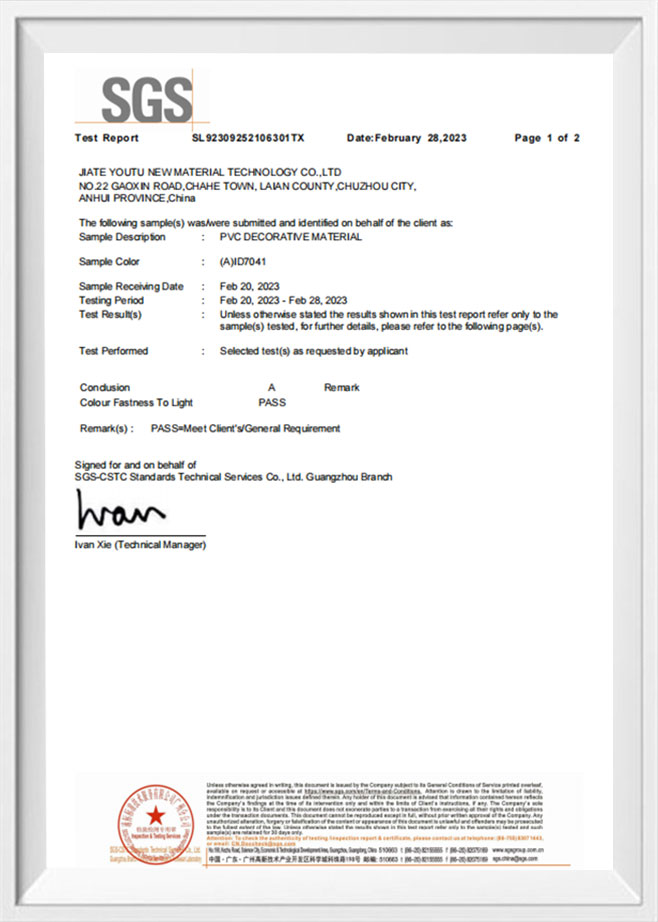

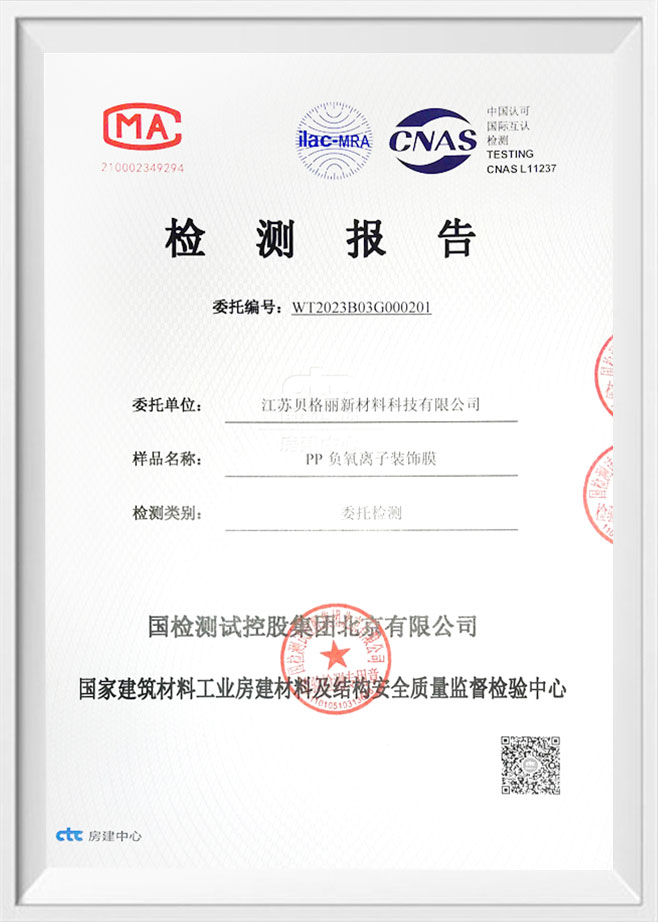

Commitment to Quality and Environmental Standards

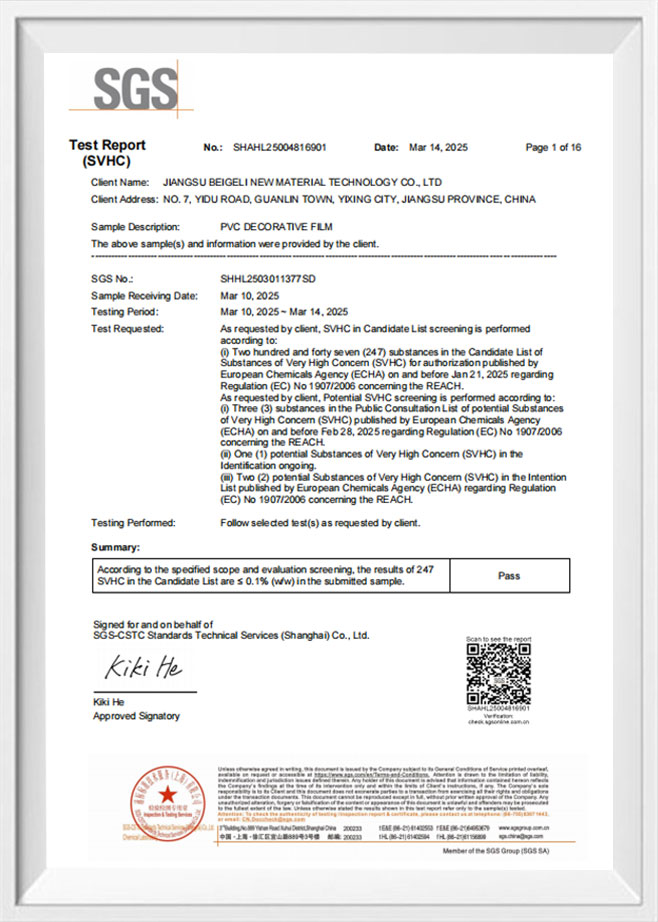

In addition to performance, today’s furniture manufacturers are under increasing pressure to use materials that align with environmental and safety regulations. Solid color ABS edge banding is free of chlorine and halogens, offering a safer and more sustainable alternative to PVC-based products. The material complies with RoHS and REACH standards, making it suitable for use in both domestic and international markets that demand eco-friendly production practices.

Jiaxing Xuanyi reinforces this environmental commitment with strict quality control procedures. Advanced testing equipment and quality management systems ensure that every batch of edge banding meets the technical and regulatory requirements necessary for safe use in homes, offices, and public spaces.

Supporting Global Design Trends

As furniture design trends continue to evolve toward minimalist aesthetics and seamless finishes, the demand for solid color ABS edge banding is expected to grow. Its ability to provide a clean, modern appearance while supporting performance and safety needs gives manufacturers a reliable material to work with. Whether creating bold statement pieces or subtle, neutral-toned furnishings, designers find solid color ABS edge banding a practical and attractive component in their toolkit.

Backed by strong technical expertise, integrated production capabilities, and a commitment to innovation, we help furniture manufacturers bridge the gap between creative design and practical manufacturing. Our support enables clients to produce high-quality, aesthetically consistent products that align with market demands while maintaining efficiency and cost control throughout the production process.

English

English Español

Español عربى

عربى