PP Decorative Film vs PVC Decorative Film Differences in Material and Use

2026-01-16

Content

- 1 Material Composition Differences Between PP Decorative Film and PVC Decorative Film

- 2 Surface Performance and Visual Characteristics

- 3 Processing Methods and Manufacturing Compatibility

- 4 Environmental and Material Stability Considerations

- 5 Typical Application Scenarios in Decorative Industries

- 6 Comparison of PP Decorative Film and PVC Decorative Film in Practical Use

- 7 How to Choose Between PP and PVC Decorative Film

Material Composition Differences Between PP Decorative Film and PVC Decorative Film

PP decorative film is produced from polypropylene, a polyolefin material known for its stable chemical structure and relatively low density. PVC decorative film is manufactured from polyvinyl chloride, which contains chlorine in its molecular structure and typically requires plasticizers to achieve flexibility. This fundamental difference in raw material composition directly influences processing behavior, surface characteristics, and application suitability.

Impact of Base Resin on Film Properties

Polypropylene-based films tend to have lower material density and a more uniform molecular structure, resulting in consistent thickness control during film production. PVC films rely on additives to modify flexibility and softness, which can affect long-term material stability depending on formulation and use conditions.

Surface Performance and Visual Characteristics

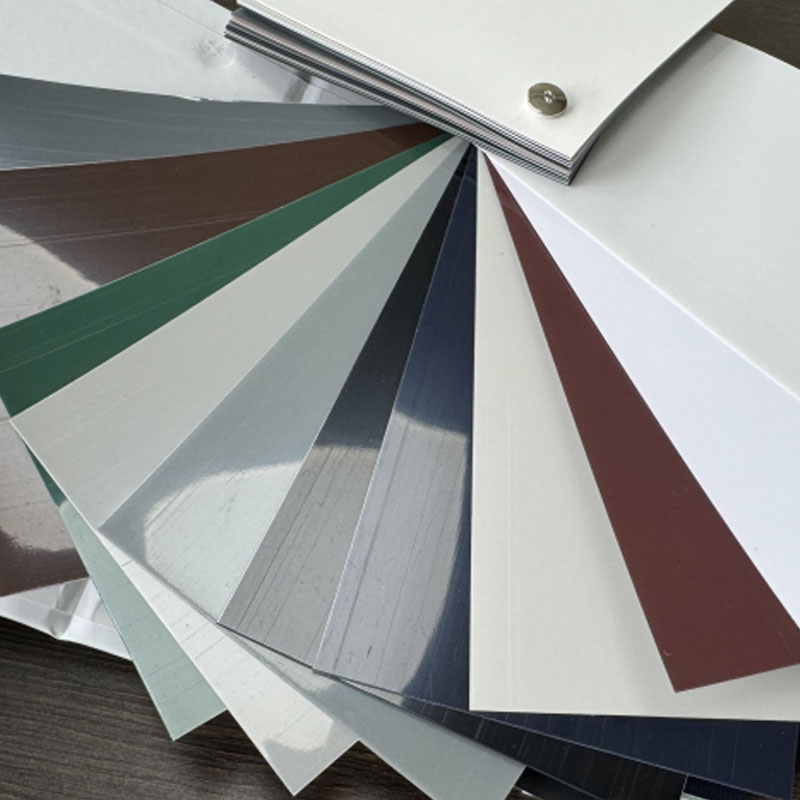

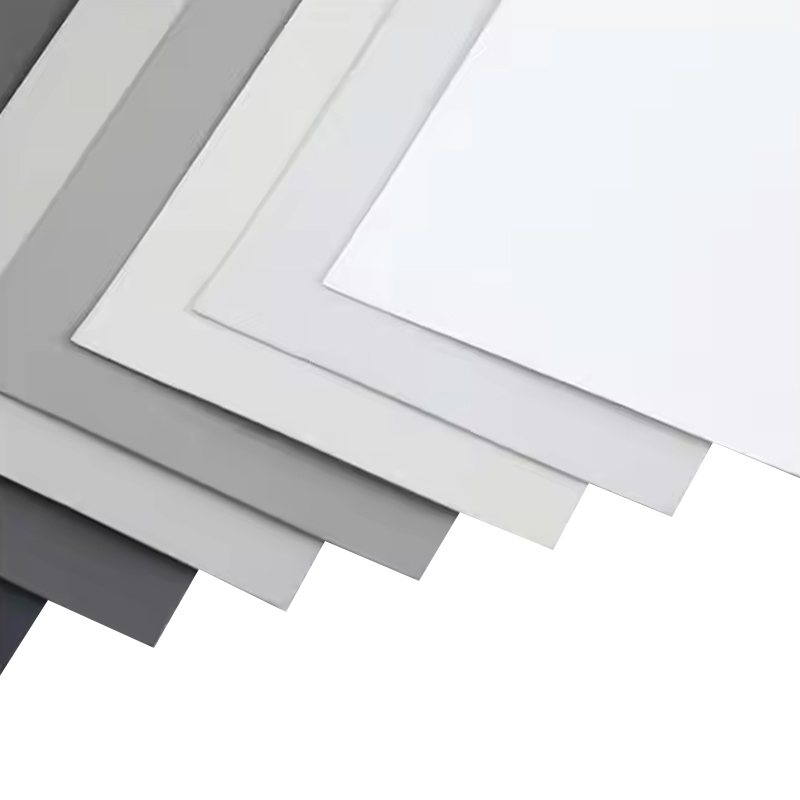

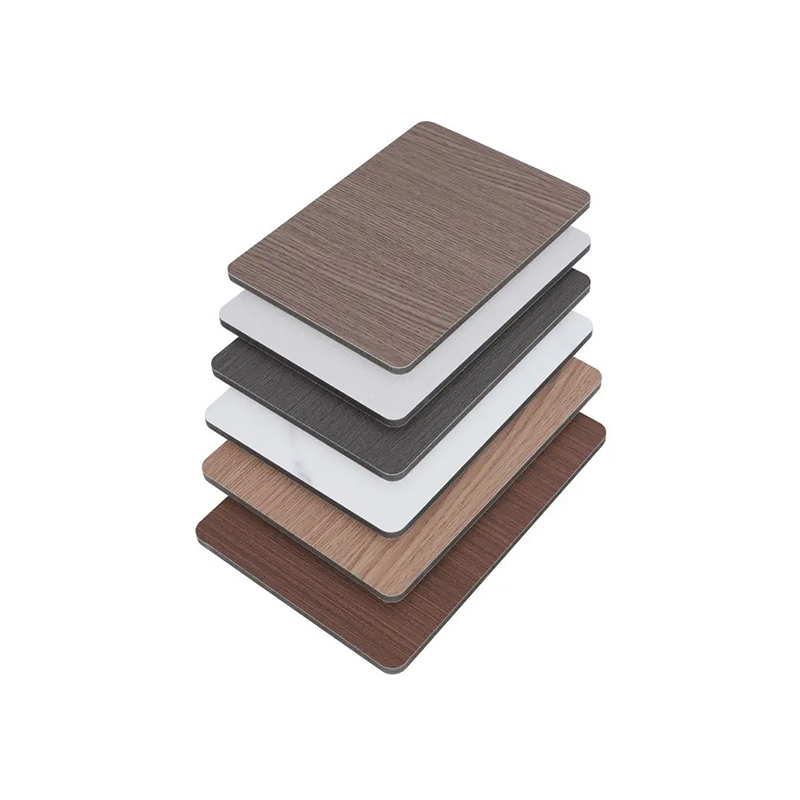

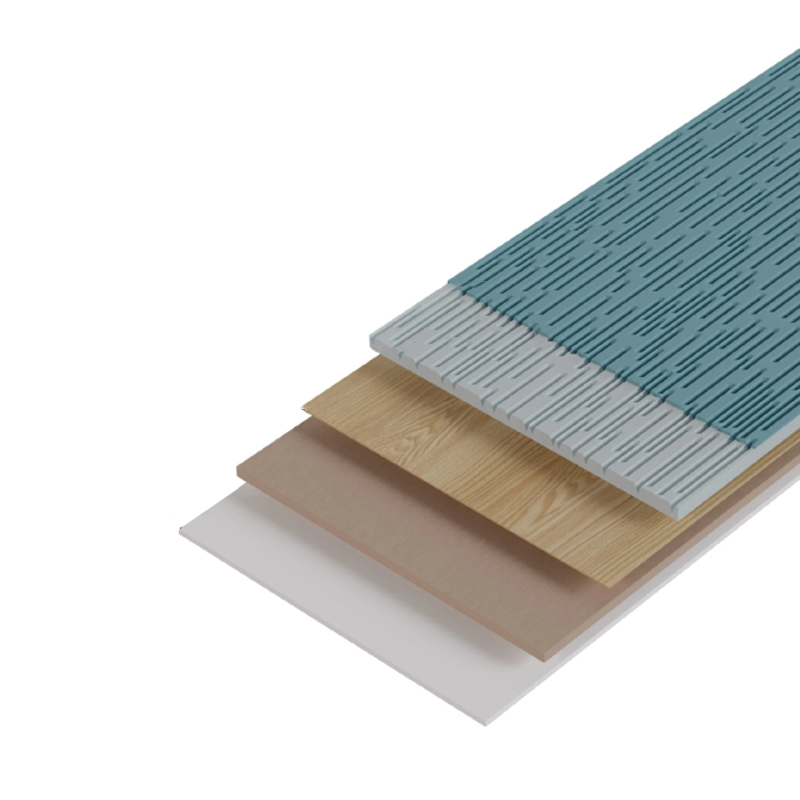

Both PP decorative film and PVC decorative film are used to replicate wood grain, stone textures, solid colors, and abstract patterns. Differences in surface feel, gloss control, and texture depth influence how each material is selected for specific decorative surfaces.

Texture Formation and Print Clarity

PP decorative film typically offers stable print definition with clear pattern edges due to its material stiffness. PVC decorative film can achieve deeper embossing effects because of its higher flexibility, making it suitable for applications where pronounced surface texture is required.

Processing Methods and Manufacturing Compatibility

PP and PVC decorative films differ in how they respond to common processing methods such as lamination, wrapping, and thermoforming. These differences affect production line setup, temperature control, and adhesive selection.

- PP decorative film is often used in flat lamination and membrane pressing processes

- PVC decorative film is commonly applied in profile wrapping and three-dimensional forming

- Processing temperature windows differ due to material softening characteristics

Environmental and Material Stability Considerations

Material stability is a key consideration when selecting decorative films for interior surfaces. PP decorative film demonstrates stable chemical resistance and does not rely on plasticizers, which supports consistent material behavior over time. PVC decorative film performance depends on formulation quality and additive selection, which can influence flexibility retention during long-term use.

Typical Application Scenarios in Decorative Industries

Both PP and PVC decorative films are used across furniture manufacturing, interior panels, and decorative components. Selection is often based on surface shape complexity, expected wear conditions, and processing equipment compatibility.

- PP decorative film for flat furniture panels, cabinet doors, and wall boards

- PVC decorative film for wrapped profiles, molded components, and curved surfaces

- Mixed use in modular furniture and interior fit-out systems

Comparison of PP Decorative Film and PVC Decorative Film in Practical Use

| Comparison Aspect | PP Decorative Film | PVC Decorative Film |

| Base Material | Polypropylene | Polyvinyl chloride |

| Flexibility | Moderate | High |

| Typical Processing | Flat lamination | Profile wrapping |

How to Choose Between PP and PVC Decorative Film

Choosing between PP decorative film and PVC decorative film depends on surface geometry, processing method, and performance expectations. Flat or slightly contoured surfaces often align well with PP film characteristics, while complex profiles and deep forming requirements may favor PVC decorative film. Understanding these material and use differences supports more consistent results in decorative surface applications.

Recommended Articles

-

1.1 What is PP Decorative Film? PP decorative film is a type of surface material made primarily from polypropylene, a versatile and widely used thermoplastic po...

View More -

Is your furniture looking tired, outdated, or damaged? Imagine transforming it effortlessly into something stunning, durable, and uniquely yours. Enter PVC deco...

View More -

1.Introduction Edge banding is a crucial finishing process used in woodworking and furniture manufacturing to cover and seal the exposed sides of materials such...

View More

English

English Español

Español عربى

عربى