Unlocking Design Potential: A Comprehensive Guide to PP Decorative Film and Customized Applications

2025-07-30

Content

- 0.1 1.1 What is PP Decorative Film?

- 0.2 1.2 Advantages of Using PP Decorative Film

- 0.3 1.3 Applications of PP Decorative Film

- 1 Customization Options for PP Decorative Film

- 2 Types of PP Decorative Film

- 3 Application Techniques

- 4 Benefits and Advantages of PP Decorative Film

- 5 Case Studies and Examples

- 6 Environmental Considerations

- 7 Future Trends in PP Decorative Film

- 8 Conclusion

1.1 What is PP Decorative Film?

PP decorative film is a type of surface material made primarily from polypropylene, a versatile and widely used thermoplastic polymer. This film serves as an excellent covering material due to its unique combination of flexibility, durability, and excellent printability. Because of these properties, PP decorative film can be used to create attractive and functional surfaces for a variety of applications.

The polypropylene base gives the film resistance to wear, moisture, and chemicals, making it suitable for both indoor and outdoor use. Its lightweight nature also adds to its ease of handling and installation compared to heavier traditional materials.

1.2 Advantages of Using PP Decorative Film

PP decorative film stands out in the market for several reasons. Firstly, it is a cost-effective solution compared to more expensive surface materials like natural wood or stone. This affordability makes it accessible for a wide range of projects without compromising on quality or aesthetics.

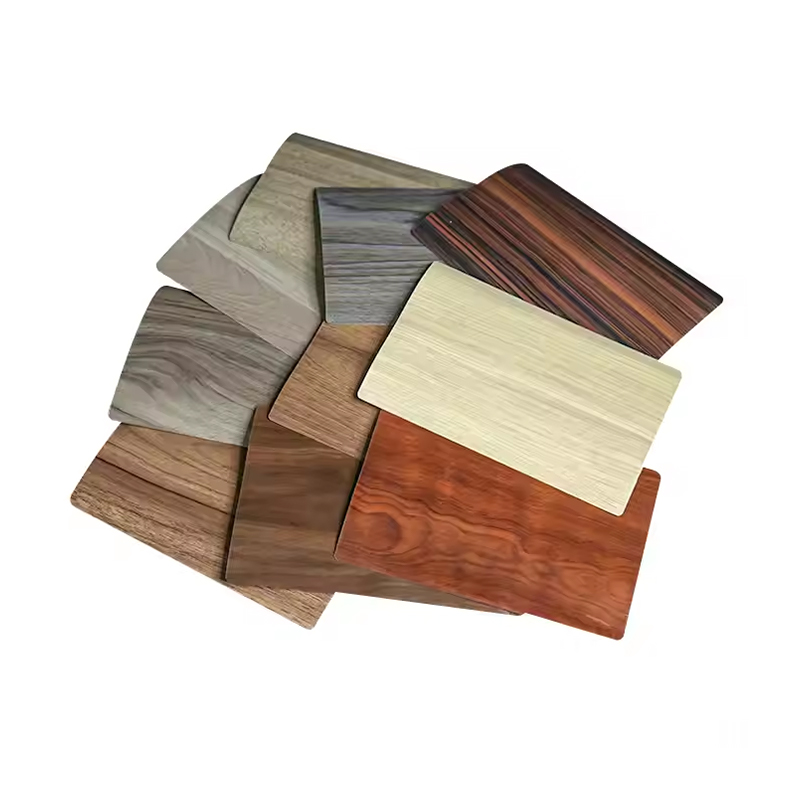

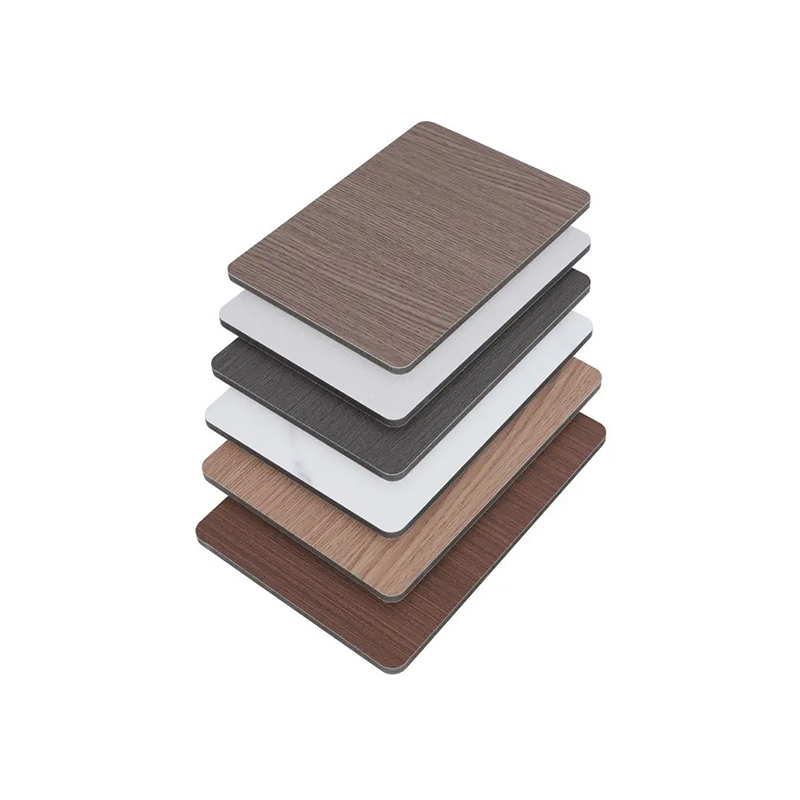

Additionally, PP decorative film offers a vast array of design options. Thanks to advanced printing technologies, it can mimic the appearance of natural textures such as wood grain, marble, and other abstract patterns. This design flexibility allows customization to match diverse interior styles and client preferences.

Moreover, PP decorative film is known for its durability. It is resistant to scratches, stains, and moisture, making it ideal for high-traffic or frequently used surfaces. Its strong wear resistance ensures long-lasting performance, reducing the need for frequent replacements or repairs.

1.3 Applications of PP Decorative Film

The versatility of PP decorative film makes it widely used across several industries. In the furniture sector, it is commonly applied to cabinets, tables, and countertops, providing an attractive finish that is both durable and easy to maintain.

Within interior design, PP decorative film enhances wall panels and decorative accents, transforming spaces with customized textures and colors. It allows designers to create distinctive environments without the expense or complexity of traditional materials.

In construction, PP decorative film is used for doors, profiles, and architectural elements, offering a lightweight yet robust option for enhancing building aesthetics and functionality. Its adaptability ensures it can meet a variety of project requirements efficiently.

Customization Options for PP Decorative Film

2.1 Printing and Patterns

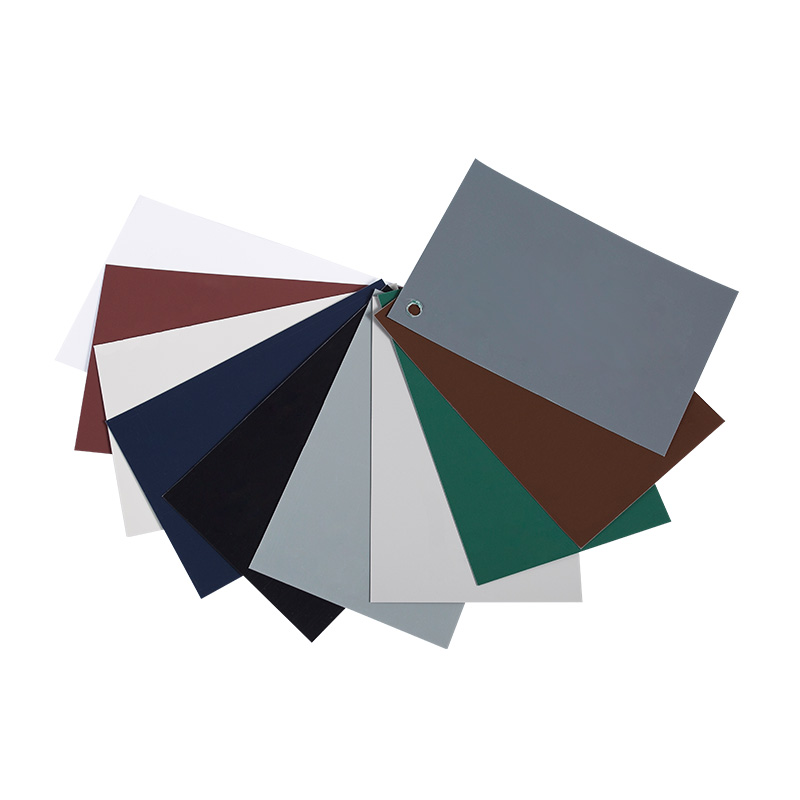

One of the major advantages of PP decorative film is its excellent printability, which enables a wide variety of design possibilities. Using advanced digital printing technologies, manufacturers can produce films with detailed and vibrant patterns. Popular designs include realistic wood grain, elegant marble, and creative abstract patterns. This flexibility allows for tailored customization that suits specific project requirements.

In addition to standard patterns, PP decorative film can also be printed with custom designs and branding elements. This makes it an ideal choice for businesses looking to differentiate their products or interiors with unique visuals.

2.2 Textures and Finishes

Beyond printed patterns, PP decorative film offers diverse textures and finishes to enhance the tactile and visual appeal of surfaces. Embossing techniques can create three-dimensional effects, adding depth and realism to the designs. This is particularly popular with wood grain and stone patterns, which benefit from textured surfaces that mimic natural materials.

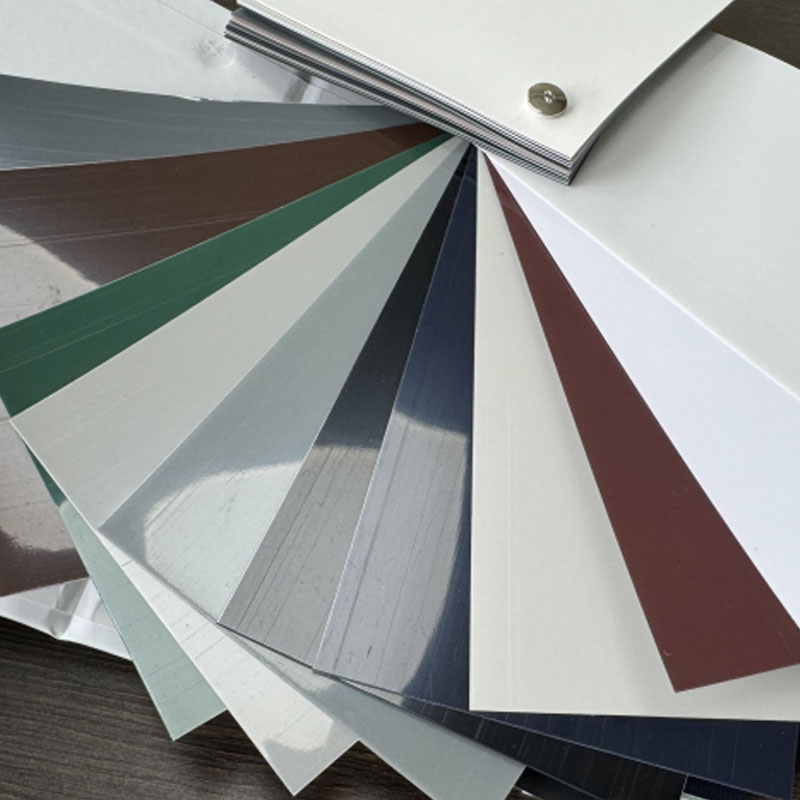

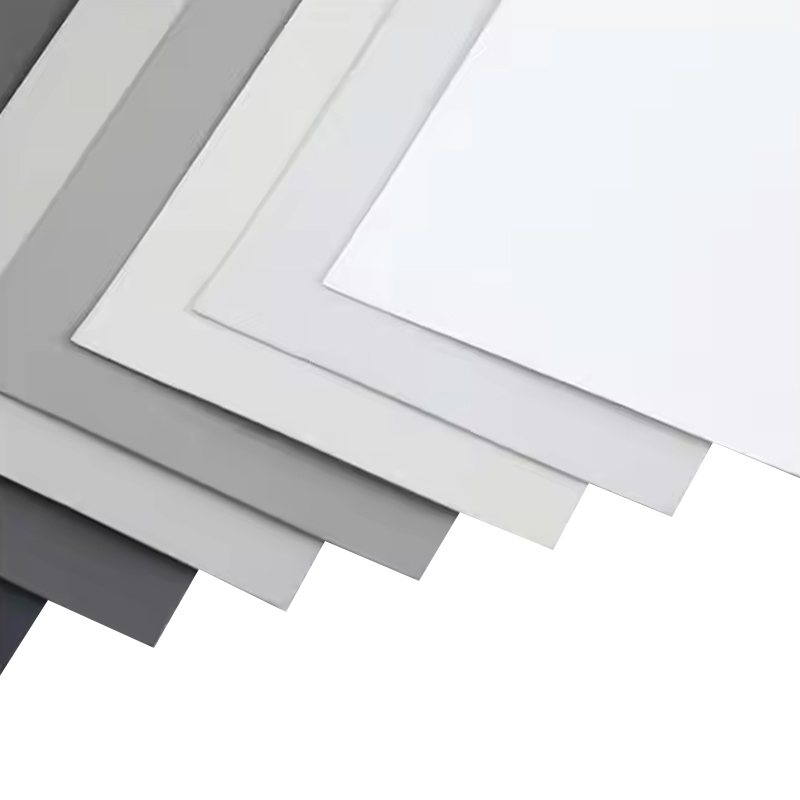

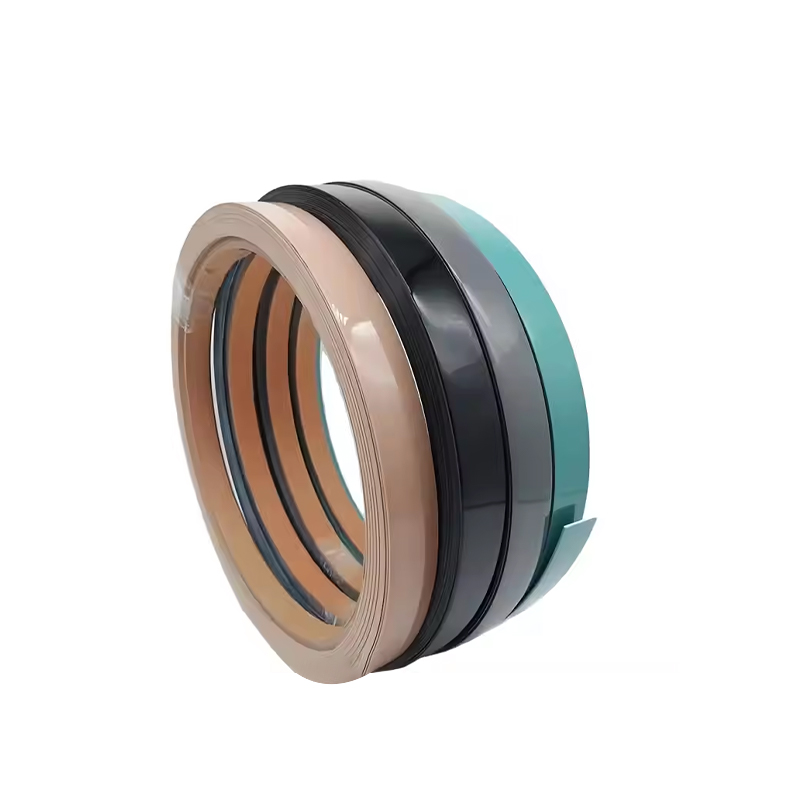

Finish options include glossy, matte, and various textured surfaces. Glossy finishes provide a sleek and modern look, while matte finishes offer a subtle and elegant appearance. Specialty finishes such as metallic or pearlescent films add a sophisticated touch, suitable for premium applications.

2.3 Size and Dimensions

PP decorative films are available in standard roll sizes but can also be produced in custom widths and lengths to meet specific project needs. This flexibility helps reduce waste and makes the material suitable for both small-scale DIY projects and large commercial applications.

Thickness options vary depending on the intended use, with thinner films suited for decorative overlays and thicker films providing additional durability and protection. The film can also be cut and shaped easily, allowing it to conform to various furniture components, architectural profiles, or other substrates.

Types of PP Decorative Film

3.1 Self-Adhesive PP Film

Self-adhesive PP decorative film is designed for easy application, making it a popular choice for DIY projects and quick renovations. This type of film comes with an adhesive backing covered by a protective liner that can be peeled off during installation. It adheres well to smooth and clean surfaces, providing a durable bond without the need for additional glue or tools.

Some self-adhesive films also offer removable and repositionable options, which allow users to adjust the placement during installation or remove the film later without damaging the substrate. This flexibility is ideal for temporary applications or renters who want to personalize their spaces.

3.2 Non-Adhesive PP Film

Non-adhesive PP film does not come with a pre-applied adhesive layer. It requires the use of external adhesives or lamination processes to attach the film to substrates. This type is often used in industrial or commercial settings where more permanent bonding is needed.

Because it can be applied with different adhesives, non-adhesive PP film is suitable for a wide variety of materials, including wood, metal, plastic, and composite surfaces. This versatility makes it valuable for specialized architectural elements and furniture manufacturing.

3.3 Protective PP Film

Protective PP decorative films are engineered to resist scratches, ultraviolet light, and other environmental factors. These films are ideal for high-traffic areas, outdoor applications, or surfaces that require extra durability.

Features of protective PP films include scratch resistance, UV resistance, and sometimes anti-fading properties, which help maintain the appearance and structural integrity of the covered surfaces over time. This makes them suitable for furniture, wall panels, doors, and profiles exposed to harsh conditions.

Application Techniques

4.1 Surface Preparation

Proper surface preparation is essential to ensure strong adhesion and a smooth finish when applying PP decorative film. The substrate must be clean, dry, and free from dust, grease, or any contaminants that could interfere with bonding.

Start by wiping the surface with a mild detergent or rubbing alcohol to remove dirt and oils. For rough or uneven surfaces, sanding may be necessary to create a smooth base. In some cases, applying a primer can improve adhesion and prevent peeling, especially on porous or newly painted substrates.

4.2 Application Methods

PP decorative film can be applied using several methods depending on the type of film and the project requirements:

Lamination: This includes both hot and cold lamination techniques. Hot lamination uses heat and pressure to bond the film to the substrate, providing a durable and long-lasting finish. Cold lamination uses pressure-sensitive adhesives without heat and is suitable for heat-sensitive materials.

Wrapping: Commonly used for profile wrapping and edge banding, wrapping involves carefully bending and fixing the film around edges and curved surfaces to provide a seamless look.

Adhesive Application: For non-adhesive PP films, selecting the correct adhesive is critical. Options include contact adhesives, water-based adhesives, or solvent-based adhesives, depending on the substrate and environmental conditions.

4.3 Post-Application Care

After applying the film, proper care helps maintain its appearance and longevity. Cleaning should be done using mild soaps and soft cloths to avoid scratches. Avoid abrasive cleaners or harsh chemicals that can damage the film surface.

Minor damages like scratches or edge lifting can often be repaired by applying heat and pressure or by patching small areas with matching film pieces. Regular inspections help catch potential issues early, extending the film’s lifespan.

Benefits and Advantages of PP Decorative Film

5.1 Cost-Effectiveness

PP decorative film offers a budget-friendly alternative to traditional materials like solid wood, laminates, or natural stone. The raw material costs for PP film are generally lower, which translates into savings for manufacturers and end users alike.

Moreover, the installation process is relatively simple and less labor-intensive, reducing overall labor costs. Precise cutting and customization also help minimize material waste, making PP film an economical choice for both small-scale and large projects.

5.2 Design Flexibility

With digital printing technology, PP decorative film can replicate the look of high-end materials such as wood, marble, or metal at a fraction of the cost. This allows designers and manufacturers to achieve complex aesthetics without the limitations of natural materials.

The ability to customize patterns, colors, and finishes enables the creation of unique designs that match any interior style or branding requirement. This flexibility expands creative possibilities and supports diverse market demands.

5.3 Durability and Maintenance

PP decorative film is highly resistant to scratches, stains, and moisture, making it well-suited for surfaces that experience regular use. Its robust nature helps maintain a fresh and appealing appearance over time.

Maintenance is straightforward: surfaces covered with PP film can be cleaned easily with mild detergents and soft cloths. Unlike some natural materials, PP film does not require special treatments or sealants, reducing upkeep effort and costs.

Case Studies and Examples

6.1 Furniture Design

PP decorative film has been widely adopted in furniture manufacturing, particularly for cabinets, tables, and countertops. For example, a furniture company used textured wood grain PP film to revamp their cabinet line, achieving a natural wood appearance without the high cost or maintenance of real wood. This not only enhanced the product’s aesthetic appeal but also improved its resistance to scratches and moisture.

Innovative designs also incorporate patterned and metallic PP films to create statement pieces. One project involved wrapping modern tables with abstract patterned PP film, resulting in unique and customizable furniture that appealed to younger consumers looking for trendy home decor.

6.2 Interior Design

In interior design, PP decorative films have transformed wall panels and decorative accents. Residential projects have successfully used marble-patterned PP film to create elegant feature walls that rival natural stone but at a fraction of the cost. Commercial spaces such as offices and hotels use PP film to update interior aesthetics quickly, with textured finishes adding depth and interest.

Customizable film options allow designers to experiment with color, pattern, and texture, helping clients achieve personalized spaces without expensive renovations.

6.3 Architectural Applications

PP decorative film is also applied in architectural elements such as door and window frame coverings, elevator interiors, and exterior cladding. For instance, a building renovation project utilized protective PP film with metallic finishes on elevator panels, providing a modern look while ensuring durability against high foot traffic and wear.

Similarly, exterior architectural profiles wrapped in UV-resistant PP film maintain their color and finish over time, even in harsh weather conditions, contributing to long-term building aesthetics and maintenance cost reduction.

Environmental Considerations

7.1 Sustainability of PP Film

Polypropylene (PP) decorative film offers several environmental benefits compared to some traditional materials. PP is recyclable, allowing used films to be processed and reused, which helps reduce landfill waste. Additionally, the production of PP film typically consumes fewer natural resources compared to solid wood or stone, contributing to a smaller environmental footprint.

Manufacturers are increasingly adopting eco-friendly production processes to minimize emissions and energy consumption during PP film manufacturing, supporting greener supply chains.

7.2 VOC Emissions

Volatile Organic Compounds (VOCs) are chemicals that can affect indoor air quality and human health. PP decorative films are available in low-VOC formulations, reducing harmful emissions and improving indoor environmental safety. These low-VOC films comply with strict environmental regulations, making them suitable for residential and commercial applications where air quality is a priority.

7.3 Life Cycle Assessment

Evaluating the environmental impact of PP decorative film throughout its life cycle—from raw material extraction to disposal—shows that it often has advantages over heavier and more resource-intensive materials. PP film’s lightweight nature reduces transportation emissions, and its durability extends product life, delaying replacement.

Compared to alternatives like laminate or natural wood veneers, PP film’s recyclability and lower energy demands position it as a more sustainable choice for decorative surfaces.

Future Trends in PP Decorative Film

8.1 Innovations in Printing Technology

Advancements in printing technology are driving exciting developments in PP decorative film. High-resolution digital printing now allows for even more detailed and realistic patterns, including three-dimensional effects that add depth and texture to surfaces. These improvements enable designers to create films that closely mimic natural materials or feature intricate custom designs.

Emerging smart films with integrated technologies, such as color-changing or light-responsive properties, are beginning to enter the market, opening new possibilities for interactive and dynamic interior design.

8.2 New Material Developments

Researchers and manufacturers continue to improve the durability and functionality of PP films. New formulations offer enhanced scratch resistance and self-healing properties that allow minor surface damage to repair itself over time. Additionally, antimicrobial and antiviral coatings are being developed to make surfaces safer in healthcare, public, and residential environments.

These innovations expand the practical applications of PP decorative films, especially in settings demanding hygiene and durability.

8.3 Expanding Applications

While furniture and interior design remain core markets, PP decorative film is finding new uses in other industries. Automotive interiors benefit from lightweight, customizable films that reduce vehicle weight while improving aesthetics. Consumer electronics manufacturers are exploring decorative films for device casings and accessories.

Medical equipment manufacturers are also adopting PP films with antimicrobial features to enhance cleanliness and safety without sacrificing design quality.

Conclusion

9.1 Recap of Key Benefits

PP decorative film stands out as a versatile, cost-effective, and durable solution for enhancing furniture, interior spaces, and architectural elements. Its flexibility in design and customization options allows for the recreation of high-end materials like wood and marble at a lower cost. Additionally, its resistance to wear, moisture, and stains makes it a practical choice for both residential and commercial applications.

9.2 The Future of PP Decorative Film

With ongoing innovations in printing technology, materials, and functional coatings, PP decorative film is poised to expand into new markets and uses. Smart films, self-healing surfaces, and antimicrobial properties will further increase its value, offering designers and manufacturers more tools to meet evolving demands.

9.3 Final Thoughts

Overall, PP decorative film represents a sustainable and innovative approach to surface decoration. Its balance of aesthetics, performance, and environmental considerations makes it a compelling option for a wide range of industries and projects. Embracing PP decorative film can unlock new design potential and contribute to more efficient and eco-friendly production practices.

Recommended Articles

-

1.1 What is PP Decorative Film? PP decorative film is a type of surface material made primarily from polypropylene, a versatile and widely used thermoplastic po...

View More -

Is your furniture looking tired, outdated, or damaged? Imagine transforming it effortlessly into something stunning, durable, and uniquely yours. Enter PVC deco...

View More -

1.Introduction Edge banding is a crucial finishing process used in woodworking and furniture manufacturing to cover and seal the exposed sides of materials such...

View More

English

English Español

Español عربى

عربى