The Ultimate Guide to Edge Banding: Materials, Techniques, and Best Practice

2025-07-24

1.Introduction

Edge banding is a crucial finishing process used in woodworking and furniture manufacturing to cover and seal the exposed sides of materials such as plywood, particleboard, or MDF. By applying a narrow strip of material—known as edge banding—along the edges of these panels, manufacturers can enhance the appearance, durability, and longevity of their products.

1.1 What Is Edge Banding and Its Purpose

At its core, edge banding serves two main functions: protection and aesthetics. It protects the raw edges of engineered wood panels from moisture, impact, and wear, while also giving the finished piece a clean, professional look. Without edge banding, furniture surfaces would be vulnerable to chipping, swelling, or delamination, especially in high-use environments or areas with changing humidity levels.

Edge banding also plays a key role in concealing the composite core of materials like MDF and particleboard, creating a seamless transition between surfaces and edges. This enhances not only the visual appeal but also the tactile experience of the finished furniture.

1.2 Importance of Edge Banding in Woodworking and Furniture Making

In modern furniture production, edge banding is more than just a cosmetic detail—it’s an industry standard for ensuring quality and longevity. Whether for residential, commercial, or institutional use, edge banding helps manufacturers deliver functional and attractive furniture that stands up to daily use. It's also essential for meeting customer expectations for smooth, safe edges, especially in environments like kitchens, offices, and schools.

From a manufacturing perspective, edge banding supports streamlined production processes by enabling modular construction and efficient panel processing. It also opens up a broad range of design possibilities with materials that mimic natural wood, metal, or high-gloss finishes.

1.3 Overview of Topics Covered

This article provides a comprehensive guide to edge banding, beginning with a detailed explanation of what it is and the materials commonly used. It explores the pros and cons of each type, techniques for applying edge banding manually and with machines, and a step-by-step look at the entire process. You'll also find insights into choosing the right adhesive, troubleshooting common problems, and selecting edge banding for specific furniture applications. Finally, design considerations such as color matching, edge profiles, and decorative styles are covered to help you achieve a high-quality finish.

2.What is Edge Banding?

Edge banding refers to the process of applying a narrow strip of material to the exposed edges of sheet materials like particleboard, MDF, or plywood. It serves as both a protective and decorative layer that enhances the overall quality and durability of the final product.

2.1 Definition

Edge banding is a finishing technique in which a thin strip—usually made of plastic, wood, or resin-based materials—is bonded to the raw edge of a wood-based panel. This strip covers the open edge, creating a smoother, more polished surface that is resistant to moisture, abrasion, and chipping. Edge banding can be applied manually or with specialized machinery, depending on the scale and precision required.

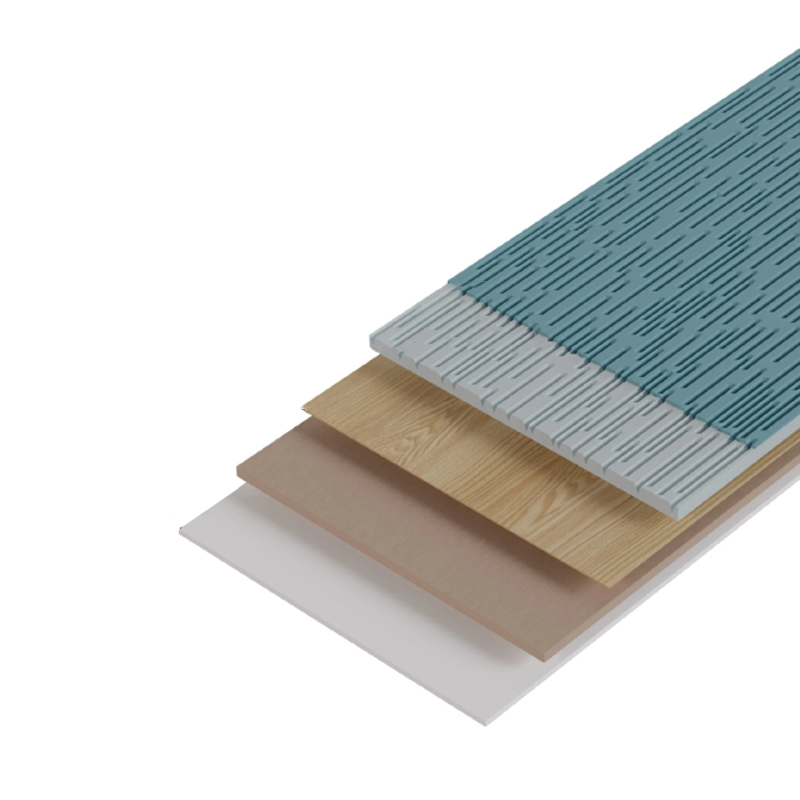

2.2 Common Materials

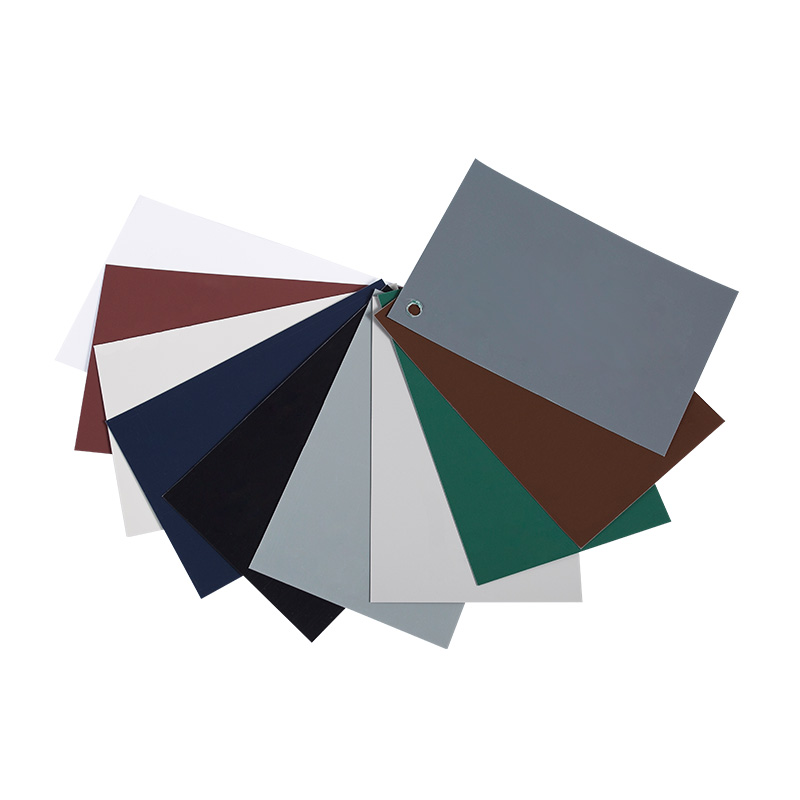

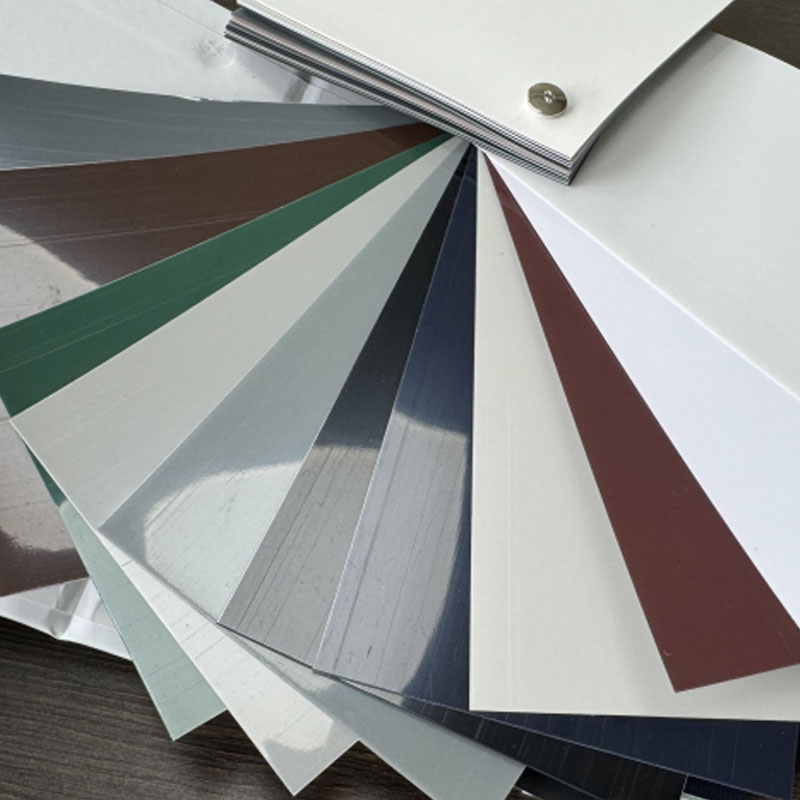

Edge banding is available in a variety of materials to meet different functional and aesthetic needs. Each type offers unique characteristics in terms of appearance, flexibility, durability, and ease of application.

2.2.1 Melamine

Melamine edge banding is a paper-based material coated with resin. It is cost-effective, easy to apply, and available in many colors and patterns. It’s often used for low- to mid-range furniture where affordability is important.

2.2.2 PVC (Polyvinyl Chloride)

PVC is one of the most widely used edge banding materials. It is flexible, durable, and available in a wide range of finishes, including wood grain, solid colors, and high gloss. PVC is ideal for high-traffic furniture and cabinetry.

2.2.3 ABS (Acrylonitrile Butadiene Styrene)

ABS is an eco-friendly alternative to PVC. It offers similar durability and flexibility but is free from chlorine and other halogens, making it a more sustainable choice. It is commonly used in green-certified furniture and projects with environmental requirements.

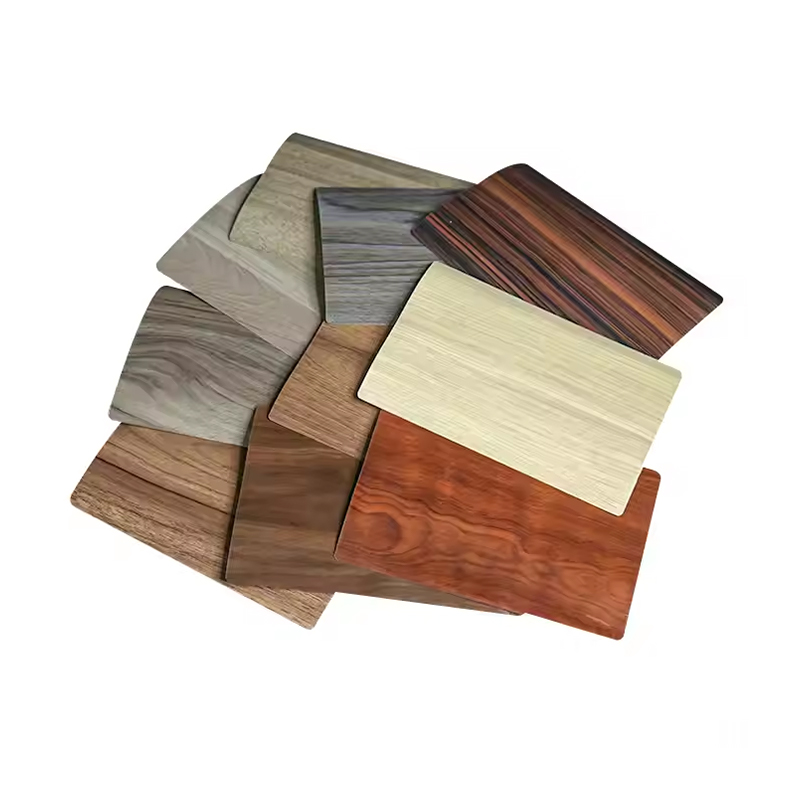

2.2.4 Wood Veneer

Wood veneer edge banding is made from real wood slices and offers a natural, authentic appearance. It can be stained or finished to match the panel surface and is often used in high-end furniture and custom woodworking.

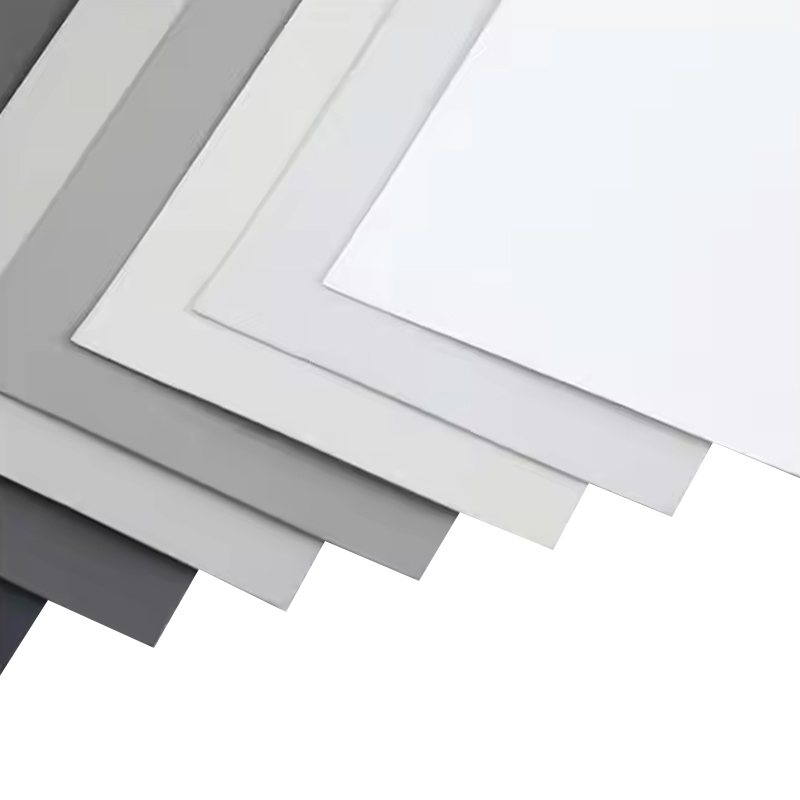

2.2.5 Acrylic

Acrylic edge banding provides a glossy, modern look and is highly scratch-resistant. It's used in contemporary designs and high-end applications where aesthetics are a top priority. It’s available in a wide range of colors and translucent effects.

2.3 Types of Edge Banding (Pre-Glued and Non-Glued)

Edge banding products are available in two primary formats based on how the adhesive is applied:

Pre-Glued Edge Banding

This type comes with a layer of hot melt adhesive already applied to the back. It is activated with heat, typically using an iron or edge banding machine, and is suitable for small-scale or DIY applications.

Non-Glued Edge Banding

Non-glued edge banding requires the separate application of adhesive, offering greater bonding strength and flexibility. It is commonly used in commercial and industrial settings with automatic edge banders that apply glue as part of the process.

3.Types of Edge Banding Materials

Each edge banding material has specific characteristics that make it suitable for different applications, budgets, and design requirements. This section outlines the most commonly used materials, along with their advantages, disadvantages, and ideal use cases.

3.1 Melamine Edge Banding

Melamine edge banding is made from a paper base infused with melamine resin. It is one of the most economical options and is often used in office furniture, shelving, and budget cabinetry.

3.1.1 Pros and Cons

Pros

Low cost

Wide range of colors and patterns

Easy to apply with an iron or hot air gun

Readily available

Cons

Brittle and prone to chipping

Not very durable in high-traffic or high-moisture areas

Limited flexibility

3.1.2 Applications

Bookshelves

Closet systems

Low-cost office furniture

Utility cabinets

3.2 PVC Edge Banding

PVC (Polyvinyl Chloride) is a plastic-based edge banding material that offers good flexibility and strength. It is highly versatile and commonly used in both residential and commercial furniture.

3.2.1 Pros and Cons

Pros

Durable and impact-resistant

Flexible and easy to form around curves

Available in many finishes, including matte, gloss, and textured

Resistant to moisture and heat

Cons

Not biodegradable or environmentally friendly

Can shrink or discolor with age or heat exposure

3.2.2 Applications

Kitchen cabinets

Office desks

Wardrobes and closets

Retail and commercial furniture

3.3 ABS Edge Banding

ABS (Acrylonitrile Butadiene Styrene) is similar to PVC but is free of chlorine and heavy metals. It’s a more environmentally responsible option, often used where sustainability is a concern.

3.3.1 Pros and Cons

Pros

Eco-friendly and recyclable

Similar performance to PVC

Good heat and impact resistance

Odorless and low-emission

Cons

Slightly more expensive than PVC

Limited availability compared to more common options

3.3.2 Applications

Environmentally certified furniture

Children's furniture and toys

Healthcare and educational furniture

3.4 Wood Veneer Edge Banding

Wood veneer edge banding is made from real wood and is typically used in applications where a natural wood look is required. It can be pre-finished or unfinished.

3.4.1 Pros and Cons

Pros

Authentic wood appearance

Can be stained or finished to match panels

Ideal for premium or custom furniture

Renewable and biodegradable

Cons

More expensive than synthetic options

Requires more skill to apply cleanly

Sensitive to moisture and wear if not sealed properly

3.4.2 Applications

High-end furniture

Custom cabinetry

Architectural millwork

Veneered plywood panels

3.5 Acrylic Edge Banding

Acrylic edge banding is a solid-color or translucent material with a high-gloss or matte finish. It’s used to achieve a sleek, modern look, especially in premium products.

3.5.1 Pros and Cons

Pros

High scratch and UV resistance

Rich, vibrant colors and 3D depth effects

Excellent for glossy or high-design aesthetics

Long-lasting finish

Cons

More expensive than other materials

Requires precise application

Can be brittle if mishandled

3.5.2 Applications

High-gloss kitchen cabinets

Contemporary office furniture

Decorative panels and displays

Retail and hospitality interiors

4.Edge Banding Techniques

Edge banding can be applied using either manual tools or automated machines, depending on the scale of the project, desired finish quality, and production efficiency. Understanding both methods is essential for choosing the right approach for a specific application.

4.1 Manual Edge Banding

Manual edge banding is often used in small workshops, DIY projects, or low-volume production settings. It allows for a hands-on approach and works well with pre-glued materials.

4.1.1 Tools Required

Edge banding trimmer or knife

Utility knife or chisel

Heat source (iron or heat gun)

Edge roller or block

Sandpaper or file

Clamps (optional)

4.1.2 Step-by-Step Process

Cut the edge banding slightly longer than the edge to be covered.

Position the banding on the edge with the adhesive side facing the panel.

Apply heat using an iron or heat gun to activate the adhesive. Move slowly and evenly.

Press the banding firmly using an edge roller or block to ensure full contact.

Let it cool, then trim the excess on both ends and along the edges with a trimmer or utility knife.

Smooth the edges with sandpaper or a file to remove sharp corners or glue residue.

4.1.3 Tips for Clean Finish

Use a straightedge to guide trimming tools for cleaner lines.

Apply consistent pressure when heating and pressing.

Avoid overheating, which can bubble or discolor the material.

Practice on scrap pieces before working on visible surfaces.

4.2 Machine Edge Banding

Machine edge banding is commonly used in commercial furniture production. It offers speed, consistency, and precision, making it ideal for high-volume or high-quality output.

4.2.1 Types of Edge Banding Machines

Automatic Edge Banders: Fully automated systems that handle gluing, pressing, trimming, and finishing.

Semi-Automatic Edge Banders: Require manual feeding but automate most of the bonding and trimming process.

Portable Edge Banders: Compact, hand-held machines suitable for on-site work or small production runs.

4.2.2 How to Use a Machine

Set the machine parameters (temperature, feed rate, edge thickness).

Feed the panel into the machine.

Machine applies glue, presses the edge banding onto the edge, and trims the excess.

Post-processing stations may include corner rounding, scraping, and buffing for a polished finish.

4.2.3 Benefits of Using a Machine

Consistent quality across multiple pieces

Increased speed and productivity

Precise application with minimal waste

Ability to work with a wide range of materials and adhesives

5.The Edge Banding Process: Step-by-Step Guide

Whether applied manually or by machine, edge banding follows a sequence of steps that ensure a durable bond and professional finish. This section breaks down the process from preparation to final touches.

5.1 Preparation

5.1.1 Preparing the Workpiece

Start by inspecting the panel for clean, square edges. Remove any dust, chips, or surface residue using a cloth or compressed air. For uneven edges, light sanding may be necessary to ensure full contact between the panel and edge banding material.

5.1.2 Choosing Edge Banding and Adhesive

Select the edge banding type based on the panel material, design requirements, and intended use. If you're using non-glued edge banding, choose a compatible adhesive such as hot melt, PVA, or contact cement. Color and thickness should match the panel for a seamless appearance.

5.2 Application

5.2.1 Applying Adhesive

For pre-glued banding: Use an iron or heat gun to activate the adhesive layer on the back of the strip.

For non-glued banding: Apply the adhesive to either the edge banding or the panel edge, following the manufacturer’s instructions for coverage and drying time.

Ensure even distribution and avoid excess glue, which can squeeze out and affect the finish.

5.2.2 Applying the Edge Banding

Place the banding strip along the edge, align carefully, and press it into place with a roller, block, or pressure system (if using a machine). Maintain firm, consistent pressure from end to end to ensure a strong bond.

5.3 Trimming

5.3.1 Trimming Excess

Once the adhesive has cooled and cured, trim any overhanging material along the top and bottom edges. Use an edge trimmer or sharp utility knife for clean, accurate cuts.

5.3.2 Tools for Trimming

Manual edge trimmer

Flush-cutting pliers

Utility knife

Router with trimming bit (for precision work)

Trimming tools should be sharp to avoid tearing or chipping the edge banding.

5.4 Finishing

5.4.1 Flush Trimming

Use a router or fine file to make the edge banding perfectly flush with the panel surface. This step enhances the seamless appearance and prepares the edge for additional finishing.

5.4.2 Corner Rounding

If desired, lightly round the corners or edges using a sanding block or corner rounding tool. This improves both appearance and safety, especially for furniture intended for children or high-traffic areas.

5.4.3 Sanding

Finish by lightly sanding the edge to smooth transitions and remove any sharp edges, glue residue, or irregularities. Use fine-grit sandpaper (180–220 grit) for best results.

6.Choosing the Right Adhesive

The adhesive plays a key role in how well the edge banding adheres and how long it lasts. The choice depends on the edge banding material, the application method, and the environmental conditions where the finished product will be used.

6.1 Types of Adhesives

6.1.1 Hot Melt Adhesives

Hot melt adhesives are the most commonly used in both manual and machine edge banding. They come in the form of solid pellets or sticks and are melted just before application.

Advantages:

Quick setting time

Strong bond

Compatible with most edge banding machines

Ideal for high-speed production

Common Uses:

Commercial cabinetry

Office furniture

General-purpose panel work

6.1.2 Contact Adhesives

Contact adhesives are applied to both surfaces (panel and edge banding) and allowed to dry until tacky before being pressed together.

Advantages:

Strong initial grab

No need for heating tools

Useful for complex or curved shapes

Limitations:

Longer prep time

Requires precise alignment—no repositioning once contact is made

Common Uses:

Irregular or curved surfaces

Manual applications without heat tools

6.1.3 PVA Adhesives

Polyvinyl acetate (PVA) adhesives are water-based glues often used for porous materials, including wood veneer.

Advantages:

Environmentally friendly

Strong bond on wood-based materials

Easy to clean up

Limitations:

Longer drying time

Not suitable for plastics like PVC or ABS

Common Uses:

Wood veneer edge banding

Traditional woodworking

6.2 Factors to Consider

When selecting an adhesive for edge banding, keep these factors in mind:

Material Compatibility: Ensure the adhesive bonds well with both the panel and the edge banding material.

Application Method: Some adhesives are better suited for machine use, while others are ideal for manual processes.

Drying and Curing Time: Faster adhesives improve efficiency but may be less forgiving during setup.

Moisture and Heat Resistance: For kitchens, bathrooms, or outdoor use, choose adhesives designed to resist heat and humidity.

Cleanup Requirements: Some adhesives are easier to clean than others, which matters for finish quality and maintenance.

7.Edge Banding Machines: Overview

Edge banding machines automate much of the edge banding process, increasing speed, consistency, and production capacity. From compact, portable units to full-scale industrial machines, there’s a solution for nearly every workshop or production line.

7.1 Types of Machines

7.1.1 Automatic Edge Banders

These are high-capacity machines used in industrial furniture manufacturing. They handle multiple steps in one pass—glue application, edge feeding, pressing, trimming, corner rounding, and polishing.

Key Features:

Fast, continuous processing

Precision trimming and finishing

Integrated control systems for accuracy

Supports multiple edge banding materials

Best for:

Large-scale production

High-end or high-volume furniture manufacturing

7.1.2 Semi-Automatic Edge Banders

Semi-automatic machines require manual feeding of panels but automate glue application and pressing. Some models include trimming and buffing functions.

Key Features:

Good balance of automation and control

More affordable than full automatic models

Suitable for medium production volumes

Best for:

Small- to mid-sized workshops

Custom or low-volume runs

7.1.3 Portable Edge Banders

Compact and handheld, these machines are ideal for on-site applications or smaller shops. They typically use pre-glued or hot melt edge banding.

Key Features:

Lightweight and mobile

Easy to operate

Limited to straight edges or gentle curves

Best for:

Repairs and installations

Custom woodworking

Low-volume projects

7.2 Features to Look For

When selecting an edge banding machine, consider the following features based on your workflow and production needs:

Glue System Type: Choose between EVA, PUR, or dual-glue options for greater flexibility.

Panel Size Capacity: Ensure the machine accommodates the panel sizes you regularly work with.

Edge Thickness Range: Some machines support only thin tapes, while others handle thick edge banding for premium finishes.

Trimming and Finishing Functions: Built-in cutters, scrapers, and buffers improve efficiency and reduce manual labor.

Speed Control: Variable feed speeds allow for adjustments depending on material and complexity.

Ease of Maintenance: Look for accessible components and user-friendly interfaces.

Automation Level: Match the level of automation to your production volume and budget.

8. Troubleshooting Common Problems

Even with proper equipment and materials, edge banding issues can arise. Understanding common problems—and how to solve them—can help maintain quality and avoid rework or waste.

8.1 Peeling Edge Banding

Symptoms:

The edge banding lifts or detaches from the panel surface, especially at the corners or ends.

Causes:

Insufficient adhesive or poor bonding

Inadequate pressure during application

Contaminated or uneven panel surface

Use of incompatible adhesive for the material

Solutions:

Clean and prepare panel edges thoroughly

Apply more even, consistent pressure during bonding

Use a higher-quality adhesive or switch to a more suitable type

For pre-glued edge banding, ensure the heat source is at the correct temperature

8.2 Bubbles Under the Edge Banding

Symptoms:

Small raised areas or blisters appear under the surface of the edge banding after application.

Causes:

Trapped air during application

Uneven heat distribution

Using low-quality or old adhesive

Applying edge banding too quickly without proper pressure

Solutions:

Apply heat evenly and use a roller to press firmly from one end to the other

Avoid stretching the banding during application

Store adhesive and banding materials properly to prevent degradation

For large bubbles, reheat and re-press the area if possible

8.3 Inconsistent Adhesion

Symptoms:

Some areas bond well, while others fail or feel loose.

Causes:

Uneven adhesive application

Dirty or oily surfaces

Inconsistent heating or pressure during the process

Incompatible glue and edge banding material

Solutions:

Apply adhesive uniformly across the full length of the edge

Wipe down all surfaces before bonding

Maintain consistent temperature and pressure during the process

Use adhesive recommended by the edge banding material supplier

8.4 Chipping or Cracking

Symptoms:

The edge banding chips, splits, or cracks during or after trimming.

Causes:

Dull trimming tools

Applying too much force when cutting

Using brittle materials without pre-heating

Trimming before the adhesive has fully set

Solutions:

Use sharp, high-quality blades or bits for trimming

Allow adhesive to cool and cure fully before trimming

Pre-warm thick or stiff edge banding slightly to soften it

Use proper trimming techniques, such as cutting with the grain on wood veneer

9.Edge Banding for Different Applications

Edge banding is used across a wide range of furniture and interior design applications. Each use case has its own functional demands and aesthetic expectations. The right edge banding material and technique can improve performance, visual appeal, and product longevity.

9.1 Furniture (Tables, Desks, Chairs)

Furniture pieces are often exposed to frequent contact, impact, and wear. Edge banding in this context not only improves appearance but also protects edges from damage and moisture.

Key Considerations:

Use durable materials like PVC or ABS for commercial-grade furniture

Choose rounded or beveled edge profiles to reduce sharp corners

For high-end furniture, wood veneer or acrylic edge banding can elevate the look

Ensure strong adhesion to resist peeling in high-touch areas like desk edges and chair backs

Typical Materials:

PVC for durability

Wood veneer for custom or natural finishes

ABS for eco-friendly, impact-resistant furniture

9.2 Cabinetry (Kitchen Cabinets, Wardrobes)

Cabinetry in kitchens and closets requires edge banding that can withstand humidity, temperature fluctuations, and daily use. A seamless finish also contributes to a clean, professional appearance.

Key Considerations:

Moisture resistance is essential, especially near sinks or appliances

Color matching with doors and panel fronts is critical

For glossy or modern cabinetry, acrylic edge banding creates a striking effect

Use hot melt adhesives or PUR for strong, water-resistant bonds

Typical Materials:

PVC for flexibility and moisture resistance

Acrylic for glossy, modern styles

ABS for sustainable, durable cabinetry

Melamine for cost-effective closet interiors

9.3 Shelving (Bookshelves, Display Shelves)

Shelving edges are prone to nicks, scratches, and visible wear. Edge banding helps protect these exposed surfaces and gives shelving units a cohesive look.

Key Considerations:

Use impact-resistant materials for open shelving

Choose thicker edge banding for heavy-use shelves or commercial environments

Decorative edge banding can be used to highlight or contrast the shelf color

Typical Materials:

PVC for durability and easy maintenance

Melamine for simple, low-cost solutions

Wood veneer for built-ins or custom shelves

Acrylic for display or retail shelving with a high-gloss finish

Recommended Articles

-

1.1 What is PP Decorative Film? PP decorative film is a type of surface material made primarily from polypropylene, a versatile and widely used thermoplastic po...

View More -

Is your furniture looking tired, outdated, or damaged? Imagine transforming it effortlessly into something stunning, durable, and uniquely yours. Enter PVC deco...

View More -

1.Introduction Edge banding is a crucial finishing process used in woodworking and furniture manufacturing to cover and seal the exposed sides of materials such...

View More

English

English Español

Español عربى

عربى