How Wood Grain PET Decorative Film Meets RoHS and REACH Environmental Standards

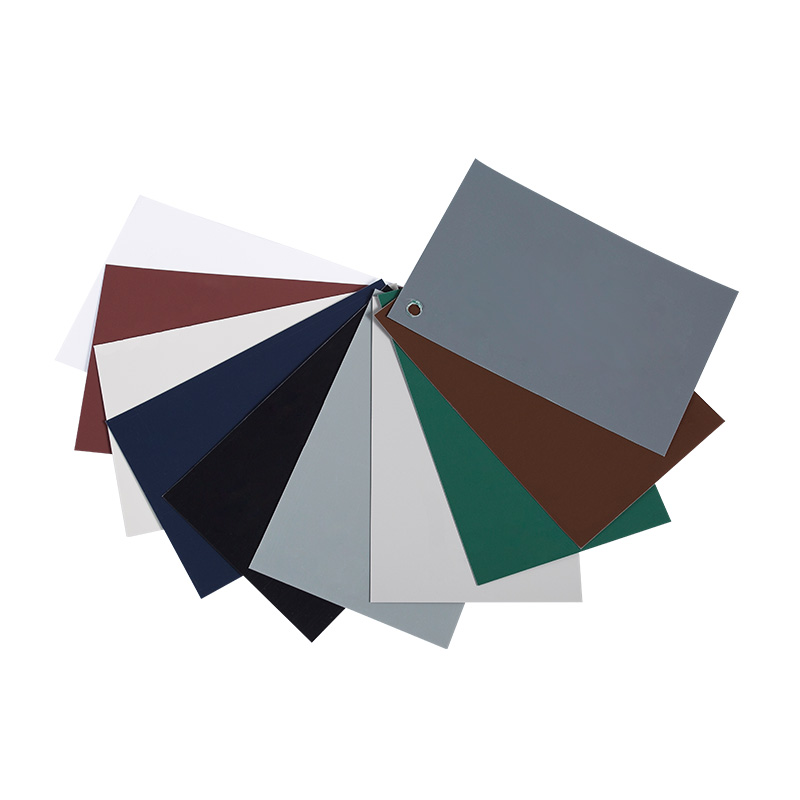

As environmental awareness continues to grow in the manufacturing and design industries, the demand for materials that comply with strict environmental regulations has become a critical factor in product selection. Wood grain PET decorative film, a high-performance surface material designed to replicate natural wood textures, not only delivers aesthetic appeal and durability but also meets important environmental standards such as RoHS and REACH. This combination makes it an excellent choice for furniture, architectural cladding, and automotive interiors where sustainability and compliance are essential.

What Are RoHS and REACH Standards?

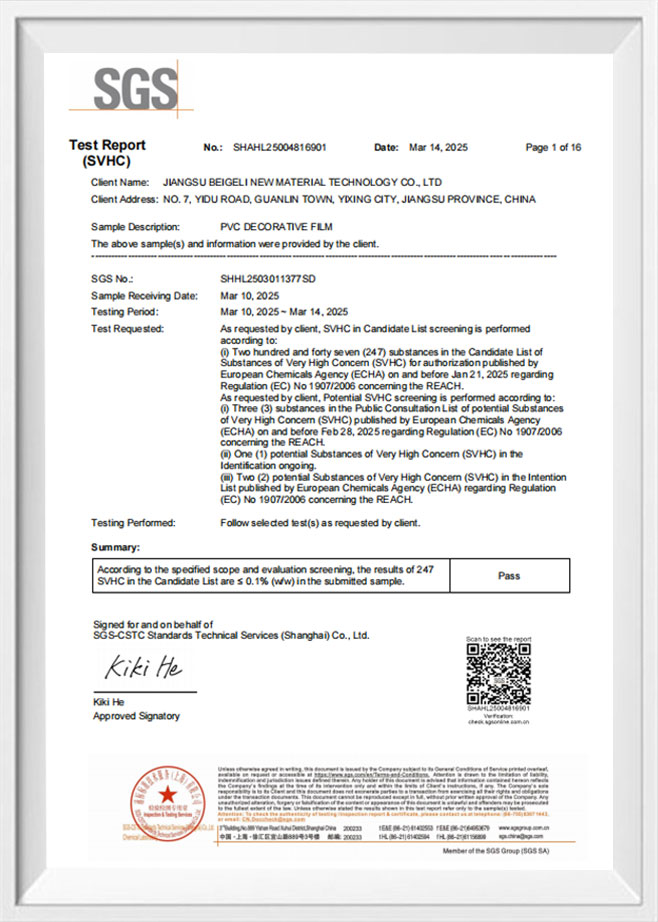

RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) are two major regulatory frameworks that set limits on the use of hazardous chemicals in materials and products. RoHS focuses on restricting substances like lead, mercury, and cadmium, which are harmful to human health and the environment. REACH requires manufacturers to assess and communicate the risks associated with chemical substances throughout the product lifecycle, promoting safer use of chemicals in consumer and industrial goods.

Wood Grain PET Decorative Film: Environmental Compliance by Design

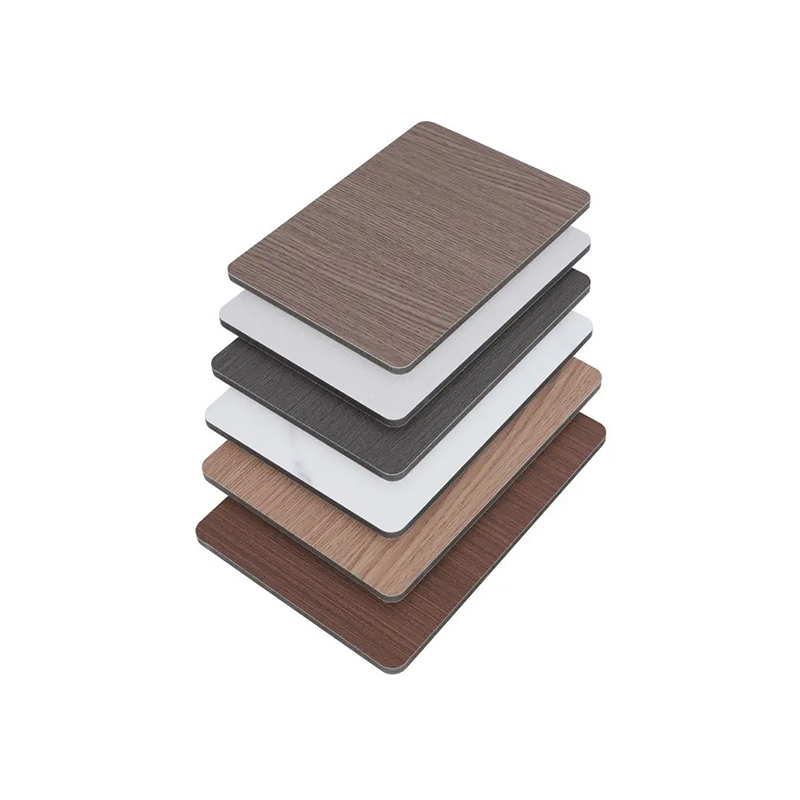

The manufacturing process of wood grain PET decorative film integrates these environmental considerations from raw materials to finished products. Made from polyethylene terephthalate (PET), this film undergoes gravure or digital printing to create authentic wood grain patterns and is protected by scratch-resistant coatings that extend its lifespan. By using PET as a base material—known for its recyclability and low toxicity—this decorative film inherently aligns with environmental safety principles.

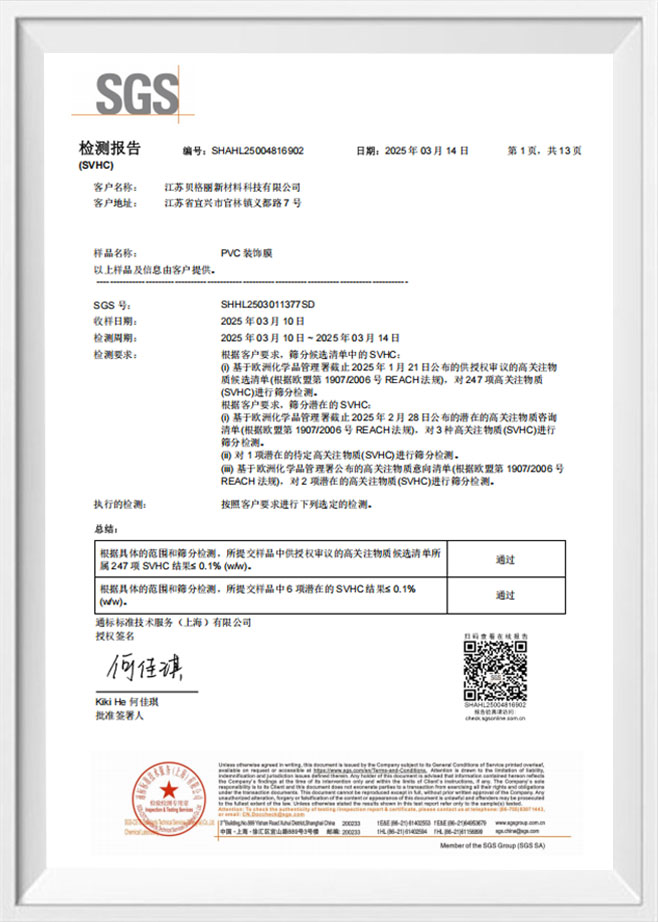

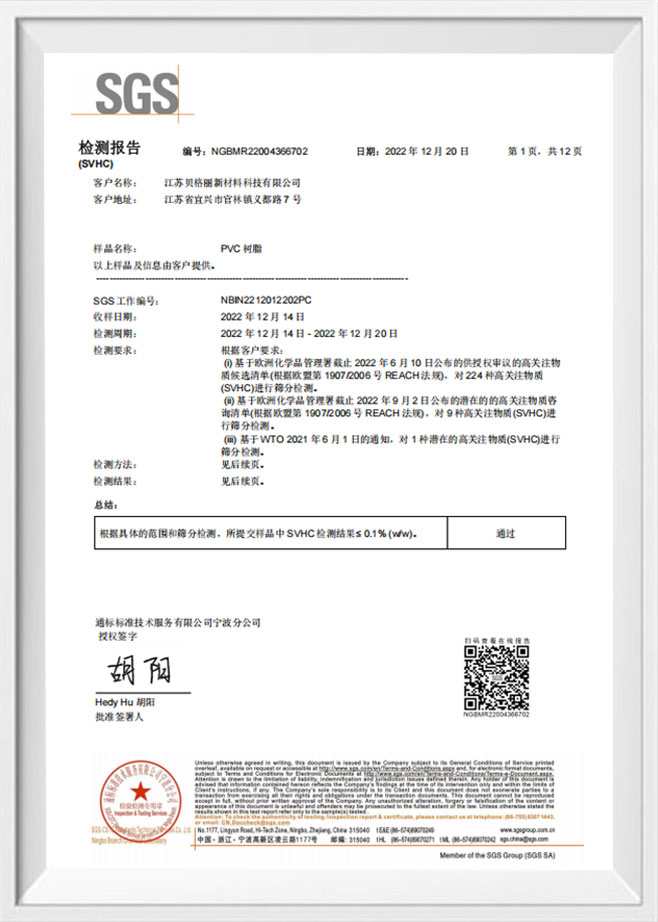

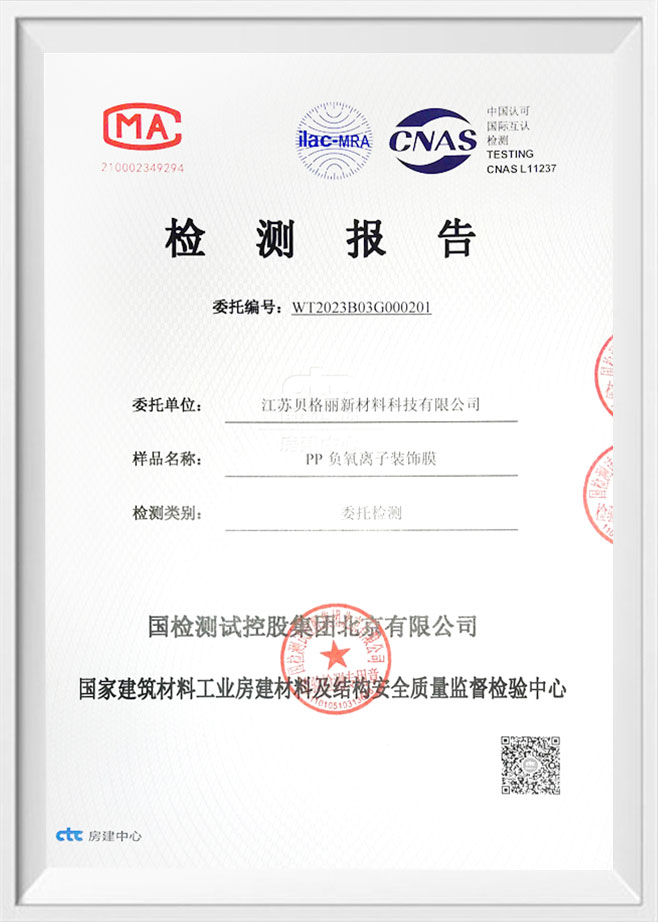

Moreover, the production adheres strictly to RoHS and REACH regulations, ensuring that hazardous substances are kept well below permissible limits. This commitment provides peace of mind to manufacturers and designers who incorporate the film into furniture, membrane doors, kitchen cabinets, or automotive interiors, knowing that the material meets global environmental safety benchmarks.

Durability and Stability Complementing Sustainability

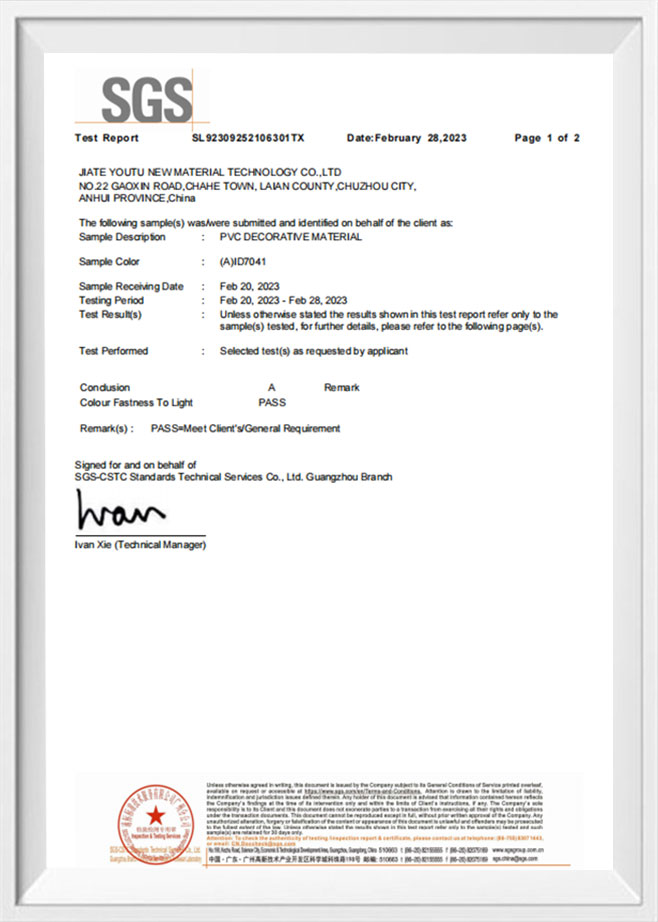

Beyond compliance, the film’s physical properties contribute to sustainability by promoting longevity and reducing waste. With a thickness ranging from 0.2 to 0.8 mm and a width of 1000 to 1420 mm, the wood grain PET film exhibits excellent tensile strength, thermal stability from -40℃ to 150℃, and strong UV resistance. These features ensure the film maintains its appearance and function over time, even under challenging conditions, reducing the need for frequent replacements.

Such durability directly supports environmental goals by lowering material consumption and waste generation over the product’s lifecycle. In addition, the scratch-resistant coatings help maintain surface integrity, preserving the decorative film’s premium look without the use of harsh chemical cleaners or coatings post-installation.

Jiaxing Xuanyi’s Commitment to Quality and Compliance

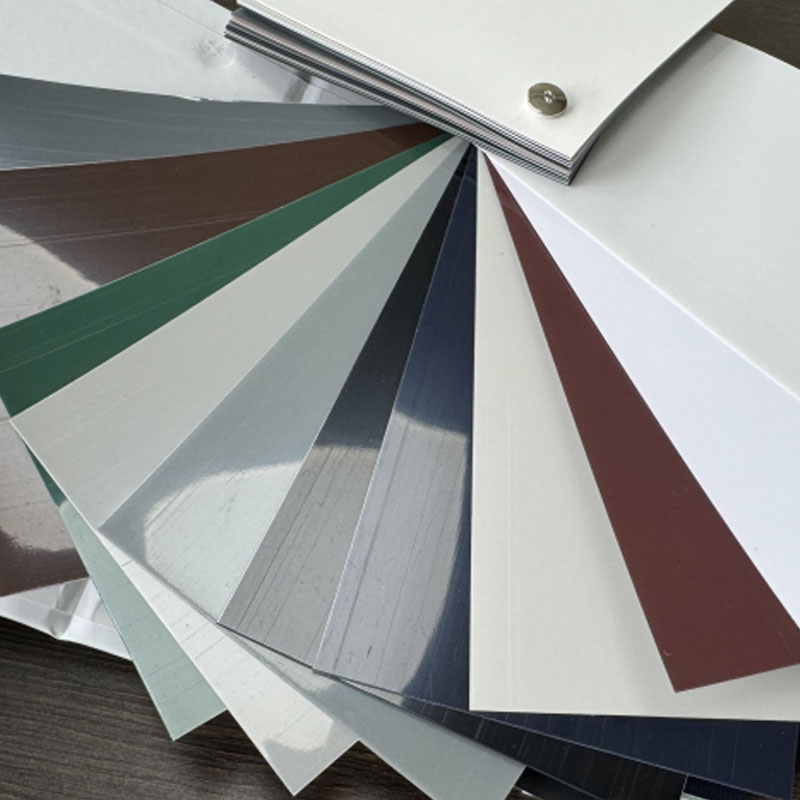

Jiaxing Xuanyi International Trade Co., Ltd, a leading manufacturer based in Jiaxing, Zhejiang province, exemplifies how integrated production processes and rigorous quality management uphold environmental standards in decorative film production. By maintaining control over raw material sourcing, calendaring, and coating processes within their own factories, the company ensures every step complies with international regulations and quality benchmarks.

Advanced inspection and measurement methods further guarantee that each batch of wood grain PET decorative film meets strict environmental and performance criteria. This approach supports Jiaxing Xuanyi’s goal to provide competitively priced, high-quality decorative films that cater to domestic and international markets with an emphasis on sustainability.

Meeting Market Demands with Innovation and Responsibility

In an industry where green building certifications and eco-friendly product offerings are increasingly valued, wood grain PET decorative film offers a compelling balance of design flexibility, technical strength, and environmental responsibility. Jiaxing Xuanyi’s dedication to innovation allows continuous enhancement of film properties while maintaining compliance with evolving regulations.

The company’s proactive approach in addressing environmental concerns positions wood grain PET decorative film as a material of choice for designers, manufacturers, and consumers aiming to reduce ecological impact without sacrificing quality or style.

Conclusion

Wood grain PET decorative film represents a forward-thinking solution that harmonizes aesthetic demands with stringent environmental requirements. By conforming to RoHS and REACH standards and demonstrating robust durability and stability, it contributes to sustainable manufacturing and design practices. Supported by Jiaxing Xuanyi’s integrated production capabilities and quality assurance, this decorative film helps shape interiors and products that respect both people and the planet.

English

English Español

Español عربى

عربى