Printing and Surface Treatment Options for PP Decorative Film

2025-10-01

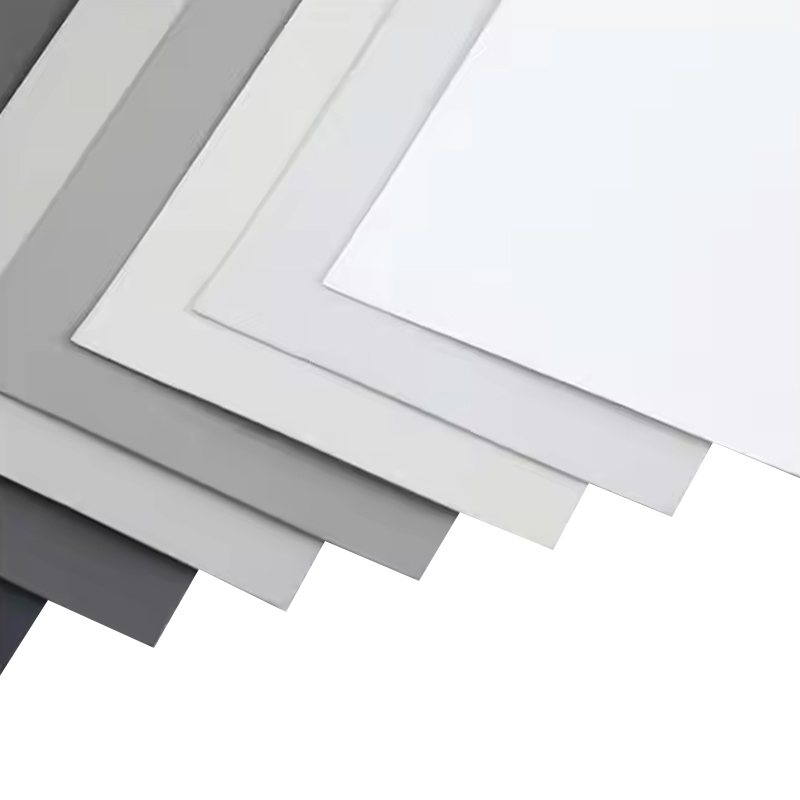

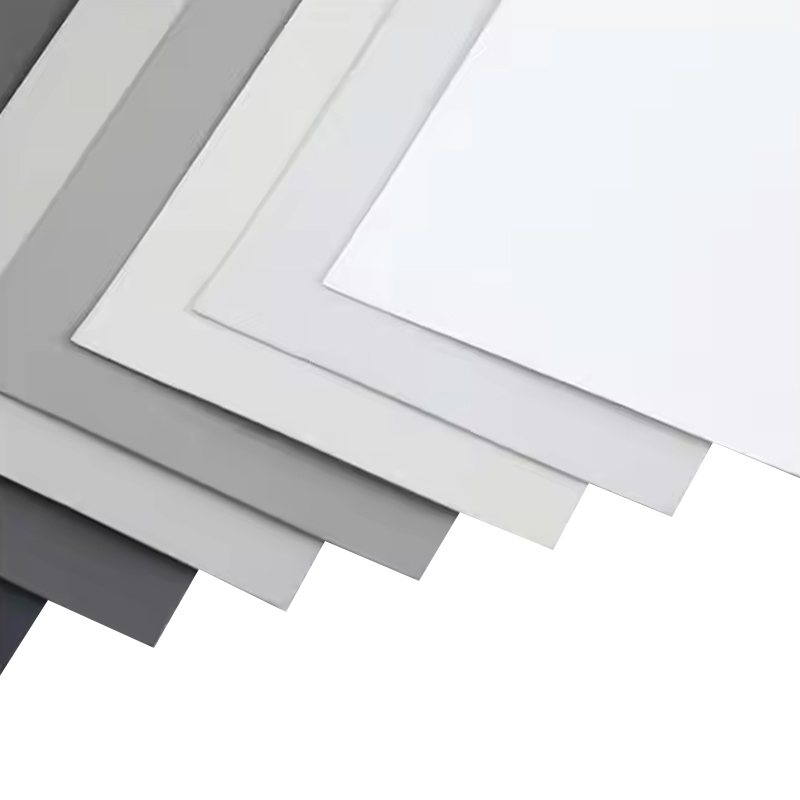

Polypropylene (PP) decorative film has gained wide application in furniture, automotive interiors, packaging, and architectural surfaces due to its lightweight, durability, and eco-friendly characteristics. To achieve visual appeal and functional performance, various printing and surface treatment methods are applied to the film. These techniques not only enhance appearance but also improve adhesion, durability, and resistance to wear, UV light, and chemicals.

Content

1. Printing Techniques for PP Decorative Film

Because PP is chemically inert and has low surface energy, printing requires specialized techniques and pre-treatment. Common options include:

-

Gravure Printing

Gravure printing is the most widely used method for PP decorative films. It delivers high-resolution images and vibrant colors, making it ideal for woodgrain patterns, metallic effects, and intricate decorative designs. Gravure printing ensures consistent ink application across large production runs, making it cost-effective for mass production. -

Flexographic Printing

Flexography uses flexible relief plates and is suitable for continuous patterns or simple graphics on PP films. It is adaptable to different substrates and allows the use of fast-drying inks, which makes it efficient for high-speed production. -

Screen Printing

For specialty applications or low-volume custom designs, screen printing can be applied to PP decorative films. This method enables thicker ink layers, metallic inks, or special tactile finishes, though it is less efficient for large-scale runs. -

Digital Printing

Advancements in digital printing now allow direct printing on PP decorative films with proper surface pre-treatment. This method offers design flexibility and quick turnaround, especially for small-batch or customized products, though ink adhesion and durability must be carefully managed.

2. Surface Treatment Methods for PP Decorative Film

To improve printability, adhesion, and overall performance, surface treatments are essential. The most common methods include:

-

Corona Treatment

A high-voltage corona discharge increases the surface energy of PP films, making them more receptive to inks, coatings, and adhesives. This is the most common pre-treatment method before printing. -

Plasma Treatment

Plasma treatment provides a more advanced modification of the PP surface, improving adhesion properties and ensuring long-lasting ink bonding. It is especially useful for high-end decorative films requiring premium durability. -

Flame Treatment

Exposing the PP film surface to a controlled flame temporarily oxidizes the surface, increasing wettability and adhesion for subsequent printing or lamination. -

Lacquer Coatings

After printing, a protective lacquer layer may be applied to enhance abrasion resistance, gloss, or matte effects. Lacquers can also improve UV resistance, protecting decorative surfaces from fading over time. -

Embossing and Texturing

Surface embossing can simulate textures such as woodgrain, leather, or stone. This not only improves aesthetics but also adds tactile appeal. Embossing can be combined with printing for a realistic, multi-dimensional effect.

3. Performance-Enhancing Treatments

Beyond printability, decorative films may undergo additional treatments:

- UV Coatings to improve light stability and prevent color fading.

- Anti-scratch Coatings to protect surfaces in high-contact areas such as furniture or automotive interiors.

- Anti-fingerprint Treatments for smooth, glossy films to maintain a clean appearance.

Conclusion

Printing and surface treatment are essential in the functional and aesthetic performance of PP decorative films. Gravure printing combined with corona or plasma treatment is the most common solution for large-scale, detailed decorative patterns. However, new methods like digital printing and advanced coatings are expanding customization possibilities. With ongoing innovation in eco-friendly inks, recyclable coatings, and surface treatments, PP decorative films continue to evolve to meet both design demands and sustainability requirements.

Recommended Articles

-

1.1 What is PP Decorative Film? PP decorative film is a type of surface material made primarily from polypropylene, a versatile and widely used thermoplastic po...

View More -

Is your furniture looking tired, outdated, or damaged? Imagine transforming it effortlessly into something stunning, durable, and uniquely yours. Enter PVC deco...

View More -

1.Introduction Edge banding is a crucial finishing process used in woodworking and furniture manufacturing to cover and seal the exposed sides of materials such...

View More

English

English Español

Español عربى

عربى