PETG Decorative Film Manufacturers

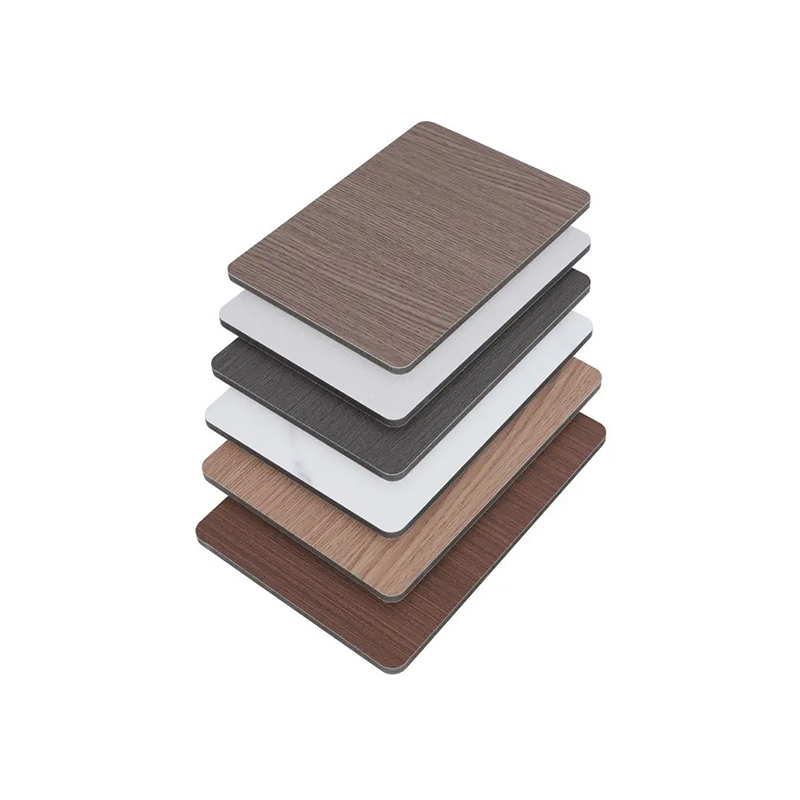

Our PETG decorative film is widely favored in the field of decoration thanks to its significant advantages. First, its excellent high transparency and glossiness can greatly enhance the visual beauty and overall texture of the decoration.

Secondly, the excellent weather resistance of PETG material ensures that the decorative effect remains as long as before in harsh environments such as ultraviolet rays and high and low temperatures.

Furthermore, its wear-resistant and scratch-resistant properties allow the decorative surface to remain flat and beautiful in daily use, resisting friction and scratches.

In addition, PETG decorative film also has good processing performance and environmentally friendly and non-toxic characteristics, as well as excellent chemical stability, is easy to clean and maintain, and light and high-strength, easy to install and transport. At the same time, rich color options and design flexibility meet diverse and personalized decoration needs.

|

Material: |

PET |

|

HS code |

3920430090/3920490090 |

|

Thickness: |

0.15mm-0.60mm |

|

Width: |

1000mm-1400mm, support customize |

|

Length: |

100-550m/roll |

|

Design |

Wood grain, Solid color, Marble, etc |

|

Surface |

Embossed, Matt, High gloss, Super matt, Soft touch, |

|

Application |

Membrane Press, Laminating, Profile Wrapping |

|

Application substrate |

PVC, WPC, TPR, SPC, Profiles, aluminum, PVC, wood, Flat panels, plywood panel, MDF panel, particle board, metal sheet, etc |

|

OEM/ODM: |

Support |

|

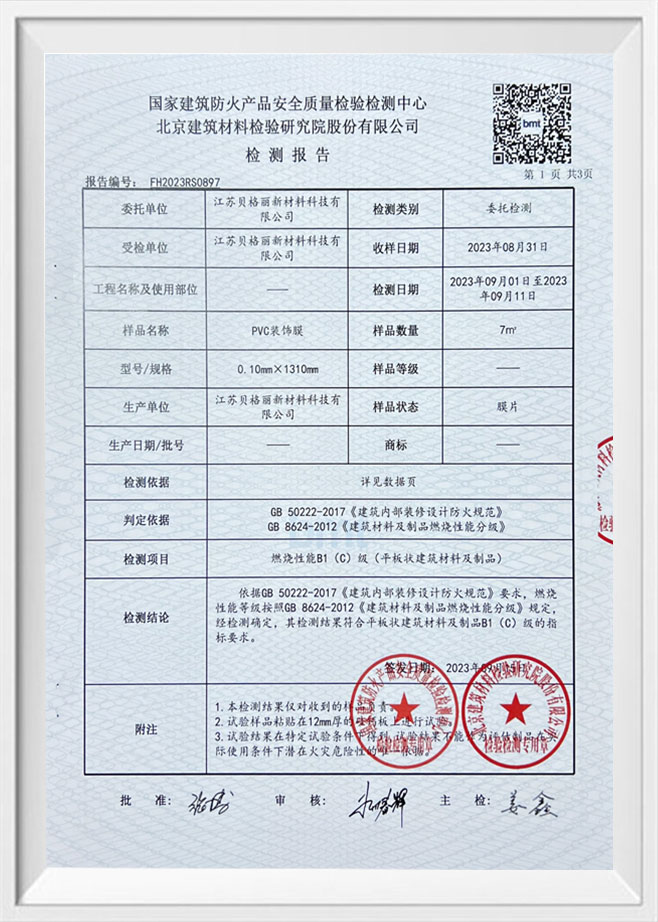

Features: |

1Eco-friendly 2. High quality&Sturdy 3.Waterproof&Fireproof 4.Wear-resistant&Chemical resistant 5.Unfading&Easy to clean 6. High saturation 7. Exquisite&Rich in colors |

|

Thickness suggested |

Interior door.0.12-0.20mm Furniture:0.14-0.35mm Wainscot or Dado and Ceiling:0.14-0.20mm Kitchen cabinet door:0.25-0.60mm Wall Panel /Window sill/Door frame:0.12-0.20mm |

About Us

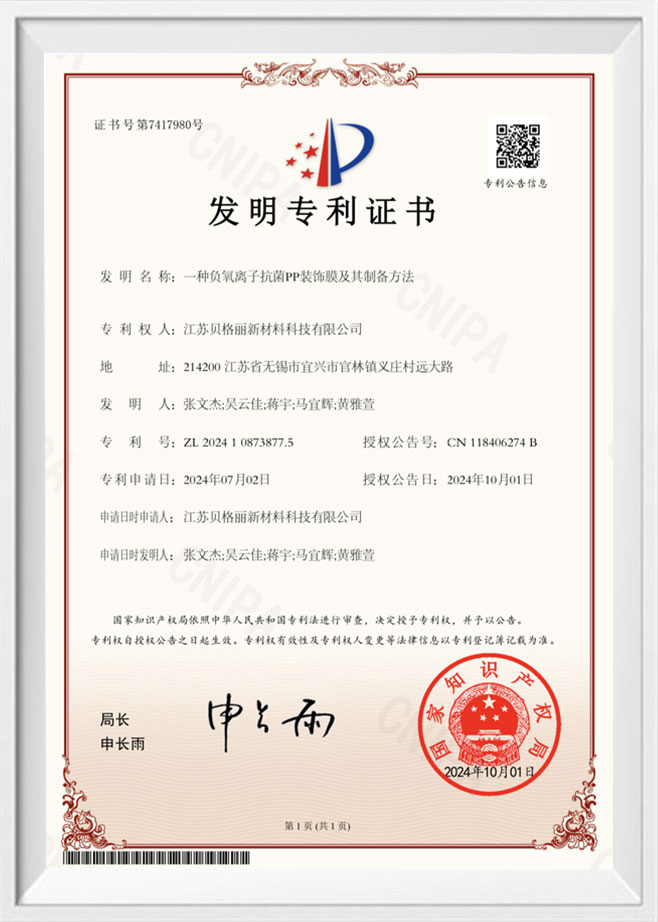

Jiaxing Xuanyi International Trade Co.,Ltd is a professional decorative film manufacturer located in Jiaxing City, Zhejiang Province. As OEM/ODM PET Decorative Film Manufacturers and PETG Decorative Film Factory in China. We have our own raw material factory, calender factory, and Coating factory, forming a unique supply chain that enables us to achieve maximum cost control and offer competitive prices and high-quality products directly.

Jiaxing Xuanyi mainly engages in producing all kinds of decorative film for vacuum press, flat lamination, and profile wrapping furniture, and the interior decoration industry. Products include matte solid color series, matte wood grain series, high-gloss solid color series, high-gloss wood grain series, anti-scratch series, soft touch series, etc.

Jiaxing Xuanyi products are widely used in domestic and abroad markets as indoor and outdoor decoration materials in membrane doors, kitchen cabinets, and other furniture industries. We offer Whoesale PETG Decorative Film for Cabinets. Equipped with advanced facilities and professional technical experts, Jiaxing Xuanyi is committed to supplying high-quality decorative films at competitive prices.

The precise instrument, together with the cautious attitude, embodies the connotation of the “Rigorous”. Jiaxing Xuanyi adopts an international quality management mode and guarantees the quality of decorative film via advanced inspection and measurement methods. Adheres to the Value of “Profession, quality, cooperation, win-win situation”, Jiaxing Xuanyi is actively pioneering in unknowing fields through technological innovation oriented to the global market based on its long-accumulated comprehensive technological strength, to continuously offer various products that can improve people’s lives and promote the progress of the whole society.

News

-

Industry News 2026-02-28

Understanding PVC, PP, and PET Decorative Films: An Overview PVC, PP, and PET decorative films are polymer-based surface covering materials manufactured in continuous roll form and...

View More -

Self Adhesive Film Wallpaper: Installation Methods, Surface Compatibility, and Long-Term PerformanceIndustry News 2026-02-19

Material Structure and Adhesive Technology Behind Self Adhesive Film Wallpaper Self adhesive film wallpaper is manufactured as a multi-layer decorative system that integrates a pri...

View More -

Industry News 2026-02-12

ABS edge banding is widely used in modern furniture and cabinet manufacturing to protect panel edges, improve visual consistency, and extend service life. Made from acrylonitrile b...

View More

Industry Knowledge

How to Optimize PETG Decorative Film for Vacuum Forming and 3D Lamination on Complex Surfaces

Vacuum forming and 3D surface lamination are essential processes for achieving seamless, high-end finishes in modern interior applications. PETG Decorative Film, thanks to its excellent formability and surface clarity, has become a top choice for designers and fabricators looking to bring out fine detailing on curved or contoured surfaces. To get the most out of PETG film in these applications, understanding its material behavior under heat and pressure is key to unlocking both its visual and mechanical performance.

One of PETG’s standout features is its low forming temperature range—typically between 120°C and 160°C—which allows it to be shaped around 3D substrates without causing discoloration, brittleness, or loss of surface gloss. This property makes it especially effective for complex cabinet door profiles or furniture components where smooth wrapping around corners and edges is critical. A controlled heating process ensures even softening of the film, reducing the risk of thinning or tearing during stretching.

During vacuum forming, uniform temperature distribution across the PETG Decorative Film for Door Panels and mold contact surface is crucial. PETG responds well to infrared and convection heating, but operators must closely monitor dwell time to avoid overheating. Proper tooling design also matters. Slight draft angles and softened radii on the mold help the film conform cleanly without excessive tension. Sharp corners may require pre-stretching or mechanical assist to avoid whitening or stress marks. These considerations are particularly relevant when producing PETG Decorative Film for wall panels with embossed patterns or custom textures.

Adhesive selection is another important factor. The film’s surface energy allows compatibility with various high-performance adhesives, but care must be taken to match adhesive type with the forming temperature and substrate material. For deep 3D forms, heat-activated polyurethane adhesives typically yield stronger bonds, especially when working with MDF or high-pressure laminate cores. This ensures that PETG Decorative Film for furniture and door panels maintains its adhesion even under frequent handling or impact.

Moisture content in substrates like MDF must be controlled before lamination, since trapped moisture can lead to surface bubbles or adhesion failure during vacuum forming. A pre-conditioning phase helps stabilize the substrate and improve bonding reliability. Equally important is pre-cleaning the PETG film surface with a non-reactive solvent to remove any residual particles or contaminants that could interfere with heat transfer or bonding.

Thickness selection depends on both the visual and structural goals of the finished part. While thinner PETG films (0.15mm–0.25mm) are suitable for detailed aesthetic layers, thicker variants (0.3mm and above) offer better impact resistance and tactile presence, making them ideal for high-touch applications like door panels and cabinet fronts. Thicker films also tend to hold embossed textures better after forming.

Another advantage of PETG Decorative Film for cabinets and furniture is its ability to maintain surface clarity and gloss even after thermoforming. This is partly due to its amorphous polymer structure, which resists haze formation during thermal cycles. For applications requiring matte or satin finishes, surface-treated PETG films are available that retain their visual consistency after forming, without surface distortion.

Color consistency across batches is a frequent concern in decorative finishing. Fortunately, PETG film production allows for tight color matching during extrusion and printing. This becomes especially important in large installations using PETG Decorative Film for wall panels, where visual uniformity across multiple sheets is non-negotiable. Coordinating color and batch codes with your supplier ensures that finish continuity is maintained throughout the project.

Handling and storage also affect processing outcomes. PETG is relatively scratch-resistant, but protective interleaving and climate-controlled storage prevent pre-processing defects. Films should be allowed to acclimate to the production environment for at least 24 hours to avoid condensation or thermal shock during forming.

With the right technical approach, PETG Decorative Film becomes a reliable solution for wrapping complex 3D shapes with precision, visual appeal, and long-term performance. As a manufacturer with years of experience delivering PETG Decorative Film for furniture and architectural use, we understand that the details—temperature, pressure, tooling, and adhesive—make the difference between average results and outstanding finishes that customers remember.

English

English Español

Español عربى

عربى