Advantages of Using PVC Decorative Foil Rolls Over Traditional Materials

2025-12-26

Content

Introduction to PVC Decorative Foil Rolls

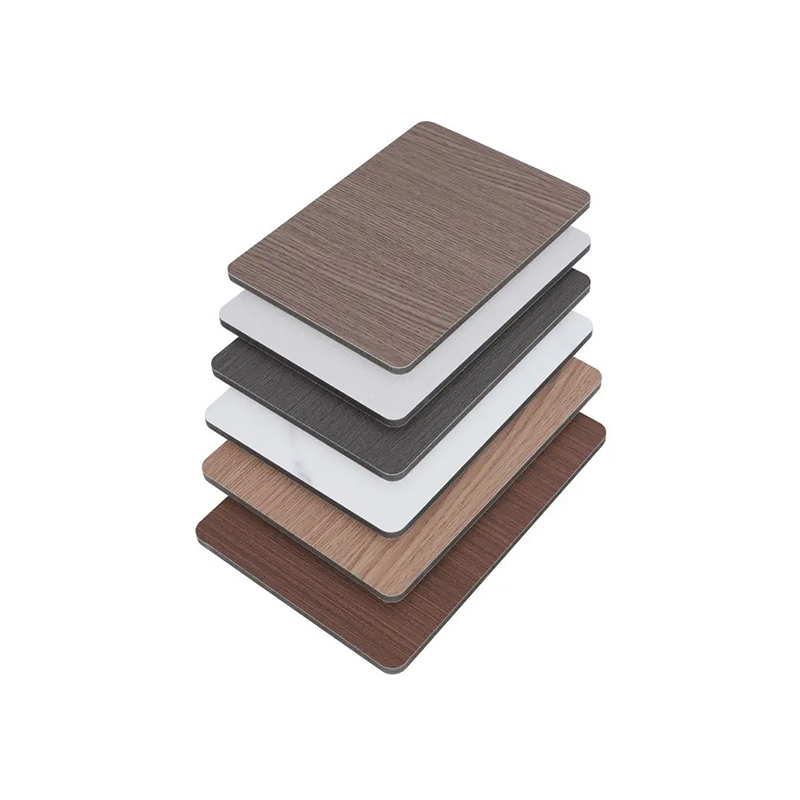

PVC decorative foil rolls have become a popular choice in interior design, furniture manufacturing, and wall panel decoration. Unlike traditional materials such as wood veneers or laminates, PVC foil rolls offer versatility, durability, and aesthetic flexibility. Their application ranges from home décor to commercial spaces, providing cost-effective and visually appealing solutions.

Durability and Longevity

One of the main advantages of PVC decorative foil rolls is their exceptional durability. They resist scratches, moisture, and wear better than many traditional materials. This makes them particularly suitable for high-traffic areas, kitchens, and bathrooms, where exposure to water and friction is common. Additionally, PVC foil is less prone to warping or cracking over time, ensuring a longer lifespan for the surfaces it covers.

Resistance to Environmental Factors

Unlike natural wood or paper-based laminates, PVC foil rolls are highly resistant to humidity, temperature fluctuations, and chemical exposure. This characteristic reduces maintenance needs and prevents deterioration, making PVC an ideal choice for environments where traditional materials might degrade quickly.

Cost-Effectiveness Compared to Traditional Materials

PVC decorative foil rolls are generally more affordable than wood veneers, solid wood panels, or high-end laminates. They offer a similar visual appeal at a fraction of the cost. Lower material costs, combined with easier installation, reduce overall project expenses while delivering high-quality results.

Simplified Installation

PVC foil rolls can be easily cut, adhered, and applied to various surfaces, including MDF, particleboard, and metal. The installation process is faster and less labor-intensive compared to veneer application or laminate pressing, saving both time and labor costs.

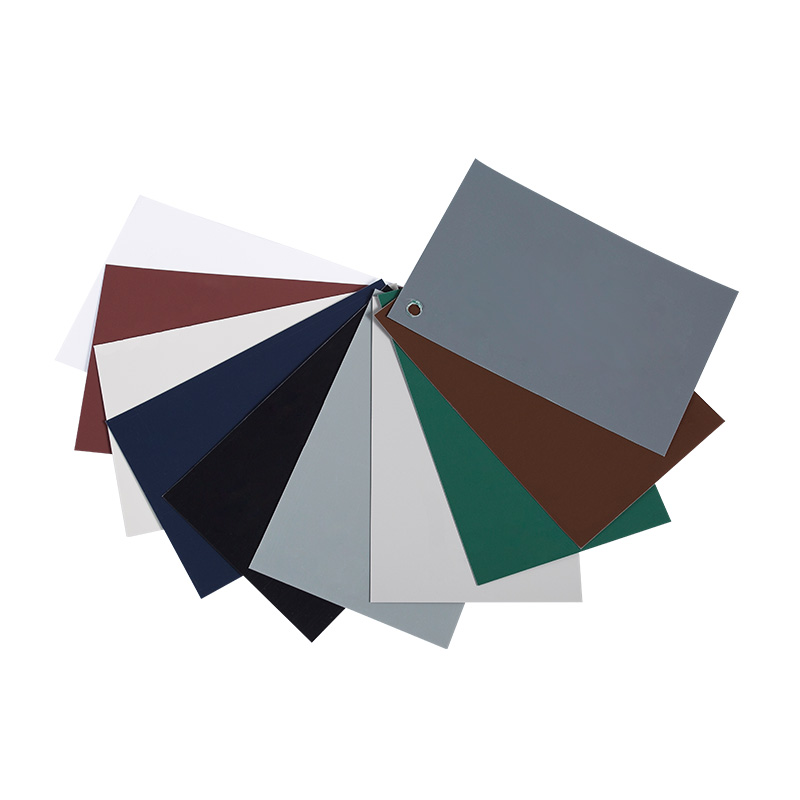

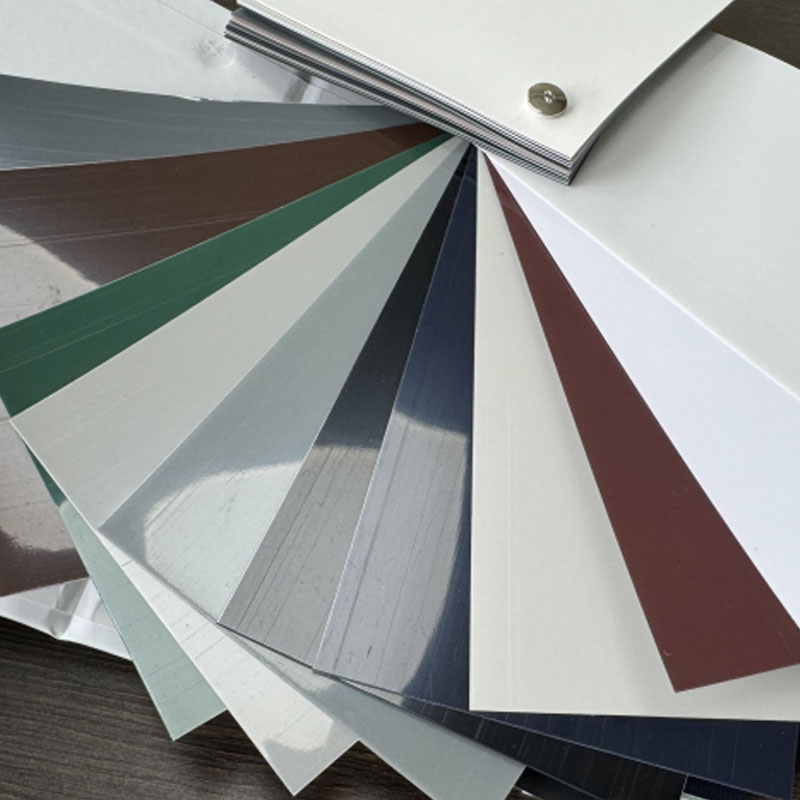

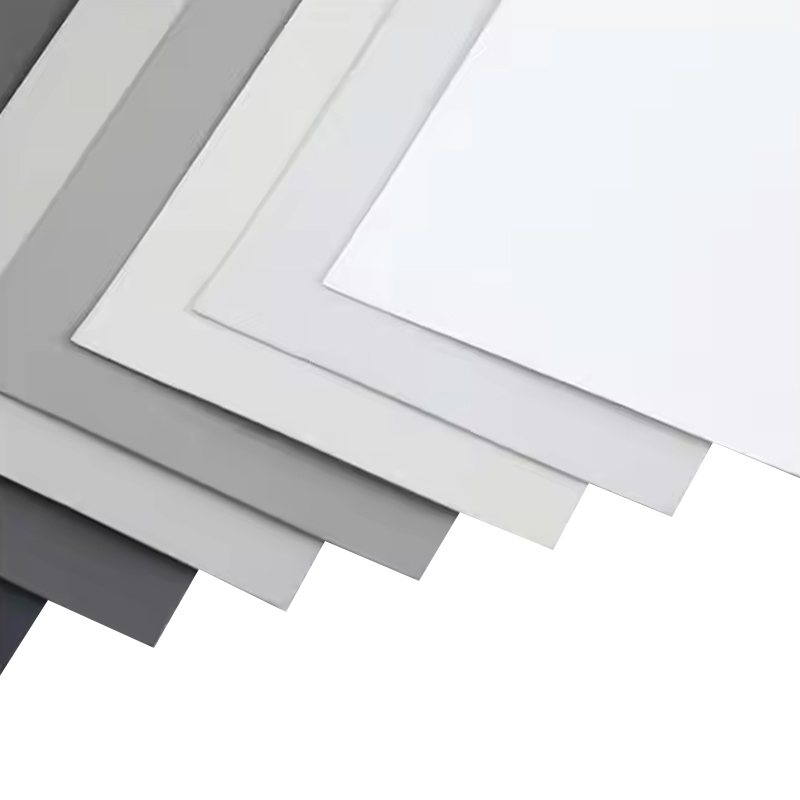

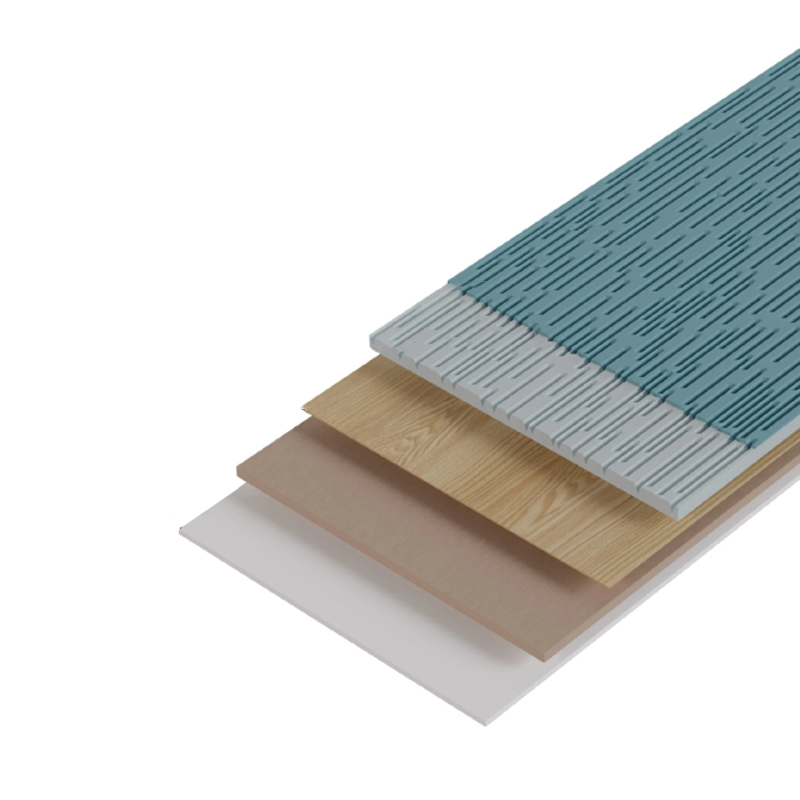

Aesthetic Flexibility and Design Options

PVC decorative foil rolls are available in a wide range of colors, textures, and patterns, from wood grain and stone effects to modern abstract designs. This variety allows designers and manufacturers to achieve sophisticated visual effects without the limitations of traditional materials. The uniformity of PVC also ensures consistent color and pattern across large surfaces, which can be difficult to achieve with natural veneers.

Customizable Finishes

PVC foil rolls can be produced with matte, gloss, or textured finishes, providing further customization for design needs. This flexibility makes them suitable for contemporary, classic, and commercial interior styles.

Environmental and Maintenance Advantages

PVC decorative foil rolls require minimal maintenance compared to traditional materials. They are easy to clean with mild detergents, reducing the need for harsh chemicals or specialized care. Additionally, many PVC foils are recyclable, offering an environmentally conscious alternative to materials that generate significant waste during production or disposal.

Comparison of PVC Foil Rolls and Traditional Materials

| Feature | PVC Decorative Foil Roll | Traditional Materials |

|---|---|---|

| Durability | High resistance to scratches, moisture, and wear | Prone to scratching, warping, or moisture damage |

| Cost | Affordable, cost-effective | Higher material and labor costs |

| Installation | Easy to cut, adhere, and apply | Labor-intensive, requires specialized tools |

| Aesthetic Options | Wide variety of colors, patterns, and finishes | Limited by natural patterns and available materials |

| Maintenance | Low, easy to clean | High, requires special care |

Conclusion

PVC decorative foil rolls provide significant advantages over traditional materials in durability, cost-effectiveness, installation ease, and design flexibility. Their resistance to environmental factors, low maintenance requirements, and wide range of aesthetic options make them an ideal choice for modern interiors and furniture projects. By selecting PVC decorative foil rolls, businesses and designers can achieve attractive, long-lasting, and sustainable results.

Recommended Articles

-

1.1 What is PP Decorative Film? PP decorative film is a type of surface material made primarily from polypropylene, a versatile and widely used thermoplastic po...

View More -

Is your furniture looking tired, outdated, or damaged? Imagine transforming it effortlessly into something stunning, durable, and uniquely yours. Enter PVC deco...

View More -

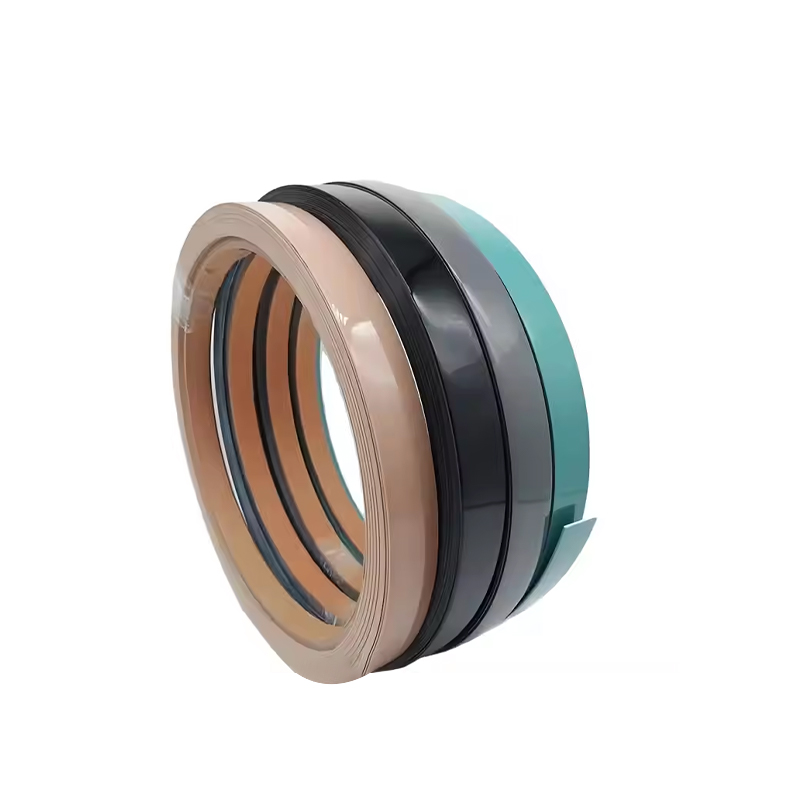

1.Introduction Edge banding is a crucial finishing process used in woodworking and furniture manufacturing to cover and seal the exposed sides of materials such...

View More

English

English Español

Español عربى

عربى