Fabric PVC Decorative Film vs Traditional Coatings: Key Differences

2025-12-08

Fabric PVC decorative film has emerged as a versatile and durable alternative to traditional coatings, offering unique aesthetic and functional advantages for interior, furniture, and automotive applications. Unlike paint, laminate, or varnish coatings, fabric PVC films combine flexibility, ease of installation, and long-term surface protection. Understanding the differences between these options helps designers, manufacturers, and installers make informed decisions for both commercial and residential projects.

Content

Material Composition and Structure

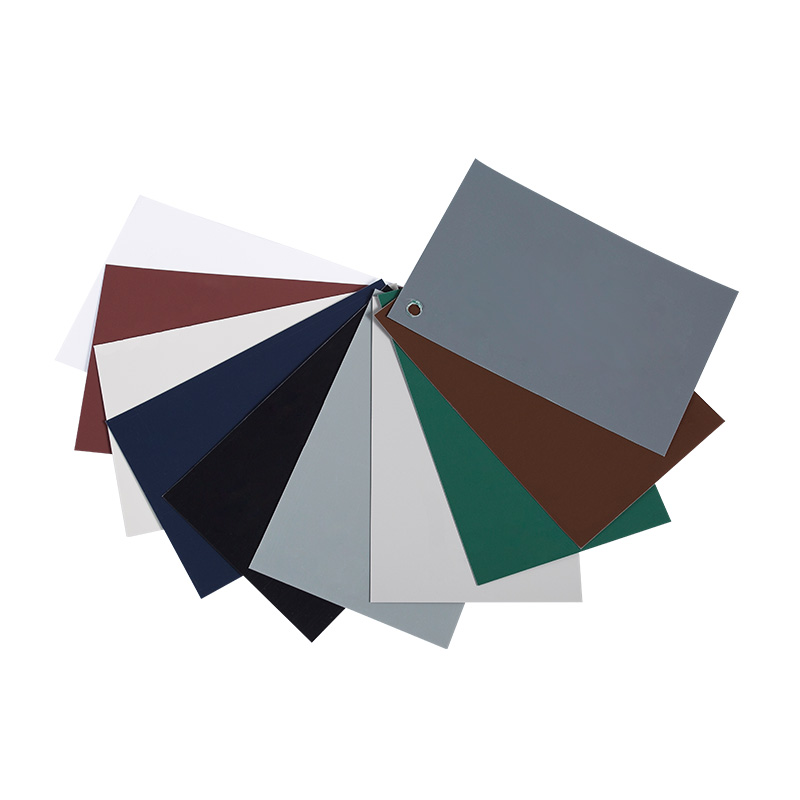

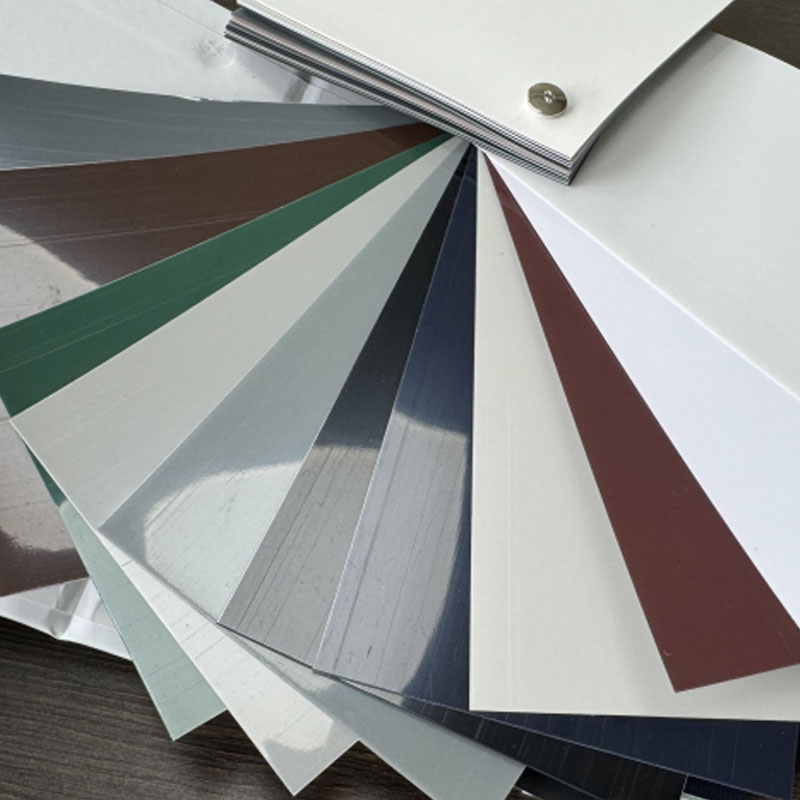

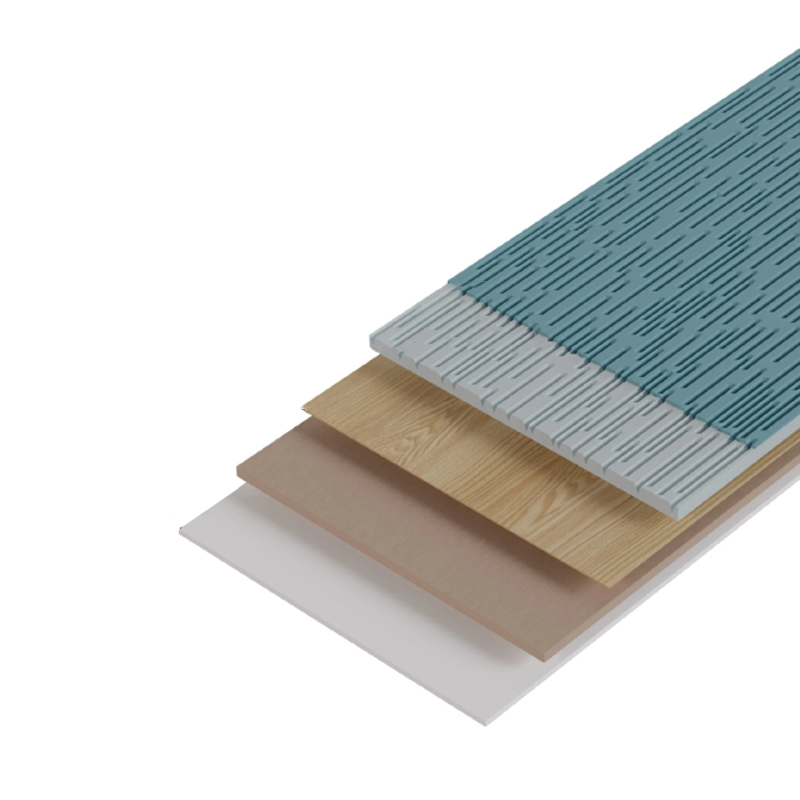

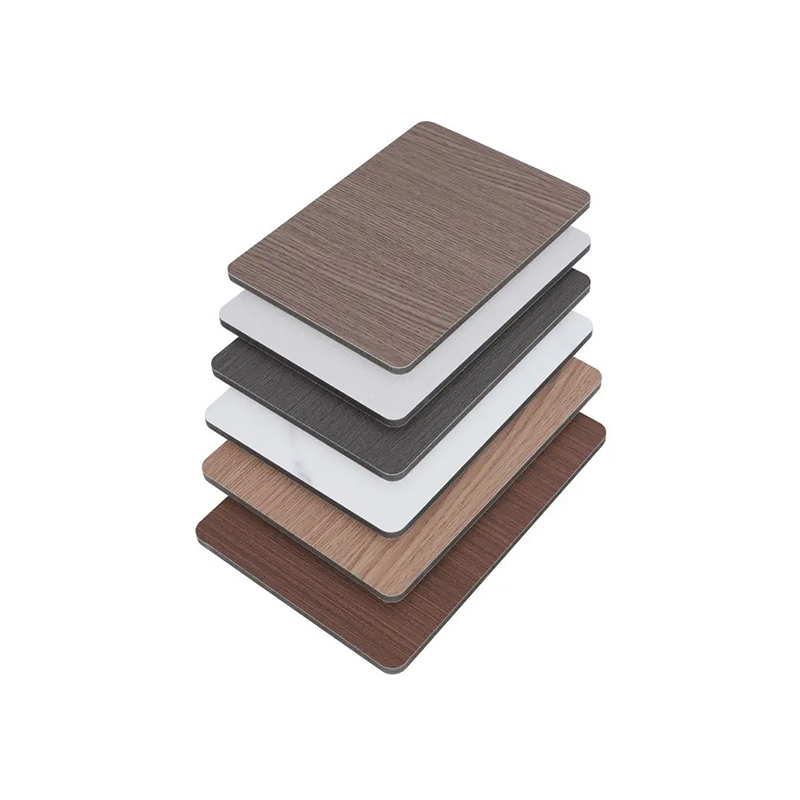

Fabric PVC decorative film is composed of a polyvinyl chloride (PVC) base layer laminated with a fabric texture or printed design. This multilayer structure enhances durability while providing a tactile, fabric-like surface. Traditional coatings, such as paints or varnishes, are typically liquid-applied materials that form a hard layer upon curing. While coatings can achieve smooth finishes, they are less flexible and prone to cracking or peeling when applied to surfaces that experience movement or expansion.

Key Advantages of Fabric PVC Film Structure

- Flexible, allowing application on curved or irregular surfaces without cracking.

- Integrated texture, eliminating the need for additional surface treatments.

- Enhanced durability against scratches, moisture, and UV exposure.

Installation and Application Differences

Applying fabric PVC decorative film involves a dry or heat-assisted lamination process, which can often be completed faster than multiple coats of traditional paint or varnish. Films can be cut to precise sizes and applied to flat or curved surfaces, reducing installation time and labor costs. In contrast, traditional coatings require surface preparation, multiple application layers, and curing times, which can extend project timelines and require specialized environmental controls for consistent results.

Comparison Table of Application Methods

| Feature | Fabric PVC Film | Traditional Coatings |

| Surface Preparation | Moderate, clean surface required | Extensive, sanding, priming, and cleaning needed |

| Application Time | Fast, can be applied in one session | Slower, multiple coats and drying times |

| Surface Flexibility | High, adapts to curves and irregular shapes | Low, may crack on curved or moving surfaces |

| Cleanup | Minimal, adhesive backing simplifies handling | Requires solvents and protective equipment |

Durability and Maintenance

Fabric PVC decorative films are highly resistant to scratches, moisture, and UV light, which helps maintain the appearance of surfaces over time with minimal maintenance. Cleaning typically involves a damp cloth or mild detergent, and the films do not require frequent reapplication. Traditional coatings can be durable when properly applied, but they are more susceptible to chipping, fading, and chemical damage, often requiring touch-ups or full repainting over time. This makes fabric PVC films particularly suitable for high-traffic areas or surfaces exposed to frequent handling.

Maintenance Tips for Fabric PVC Film

- Avoid abrasive cleaning tools that may scratch the surface.

- Use mild, pH-neutral detergents for regular cleaning.

- Inspect edges periodically to ensure adhesion is maintained.

- Avoid prolonged exposure to extremely high heat or direct flames.

Environmental and Design Considerations

Fabric PVC decorative film offers eco-friendly advantages compared to solvent-based coatings, as it produces minimal VOC emissions during installation. The ability to print or emboss patterns allows for highly customized designs without additional painting or finishing steps. Designers can create a wide range of textures, colors, and patterns, achieving consistent and repeatable aesthetics across multiple surfaces. Traditional coatings often require multiple layers and specialized equipment for complex designs, increasing labor and environmental impact.

Conclusion

Fabric PVC decorative film provides a flexible, durable, and aesthetically versatile alternative to traditional coatings. With faster installation, superior surface protection, low maintenance, and customization capabilities, it is particularly well-suited for commercial, residential, and automotive applications. While traditional coatings remain a valid choice for certain finishes or color effects, fabric PVC films offer long-term durability, environmental benefits, and practical advantages that make them an increasingly preferred solution for modern design projects.

Recommended Articles

-

1.1 What is PP Decorative Film? PP decorative film is a type of surface material made primarily from polypropylene, a versatile and widely used thermoplastic po...

View More -

Is your furniture looking tired, outdated, or damaged? Imagine transforming it effortlessly into something stunning, durable, and uniquely yours. Enter PVC deco...

View More -

1.Introduction Edge banding is a crucial finishing process used in woodworking and furniture manufacturing to cover and seal the exposed sides of materials such...

View More

English

English Español

Español عربى

عربى