How does the use of PP flooring film reduce maintenance costs during construction or renovation?

2025-11-14

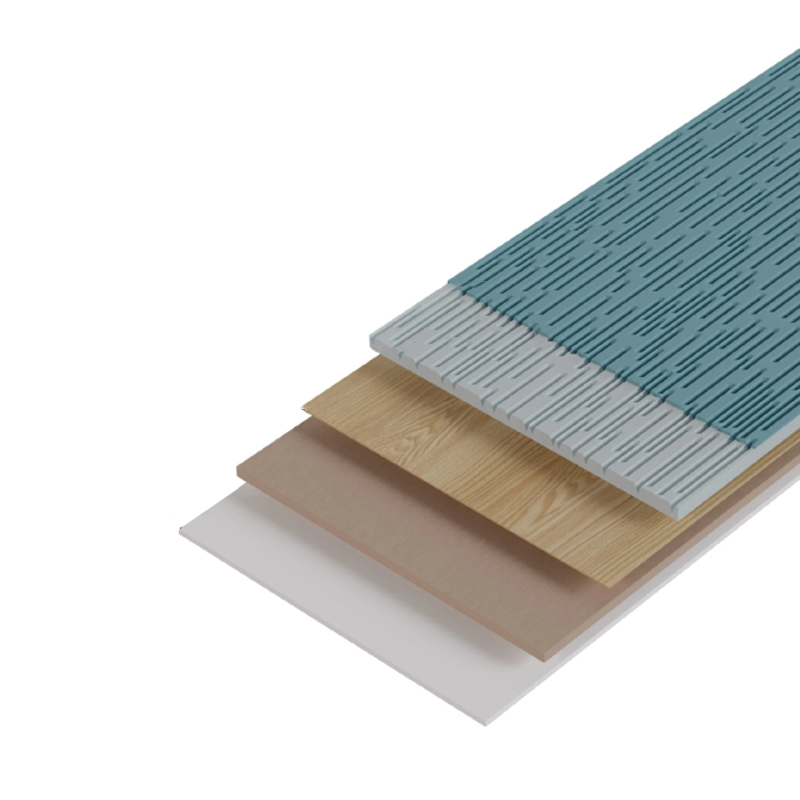

PP flooring film, made from durable polypropylene, is widely used during construction and renovation to protect finished floors from damage. By providing a temporary barrier against dirt, dust, scratches, and spills, it minimizes the need for extensive cleaning or repair after project completion, directly reducing maintenance costs.

Content

Protection Against Physical Damage

During construction or renovation, floors are subjected to heavy foot traffic, movement of equipment, and placement of tools and materials. PP flooring film acts as a protective layer, preventing scratches, dents, and scuffs that could require costly refinishing or replacement. Its toughness ensures resistance to punctures and tears even under significant pressure.

Durability and Tear Resistance

High-quality PP flooring films offer excellent tensile strength and tear resistance. These properties allow the film to maintain continuous coverage without ripping or peeling, ensuring consistent protection throughout the duration of the construction project.

Barrier Against Dust and Debris

Construction sites generate large amounts of dust and debris, which can settle into the grain of wooden floors or scratch polished surfaces. PP flooring film prevents direct contact between debris and the finished surface, significantly reducing cleaning time and labor costs after project completion.

Ease of Cleaning

Even if dust or minor spills accumulate on the surface of the film, it can be easily wiped or replaced without impacting the underlying flooring. This eliminates the need for intensive cleaning or special chemical treatments on the finished floor, further reducing maintenance efforts and costs.

Moisture and Spill Protection

PP flooring film is resistant to water, paint, adhesives, and other liquids commonly present during construction. By preventing moisture or chemical penetration, the film protects flooring from staining, warping, or corrosion, avoiding expensive repairs and ensuring the integrity of the surface.

Chemical Resistance

Polypropylene's chemical inertness makes it ideal for blocking accidental spills from paint, solvents, or cleaners. Floors covered with PP film remain unaffected, saving on restorative maintenance and material replacement.

Cost Efficiency Through Reusable and Customizable Film

Many PP flooring films are reusable or available in rolls that can be cut to size. This adaptability reduces material waste and allows contractors to apply protection only where necessary, optimizing material costs while maintaining full coverage for high-traffic areas.

Custom Sizes and Adhesive Options

PP flooring films come in various thicknesses and with optional adhesive backing. Adhesive-backed versions remain securely in place, preventing slips or gaps during work. Custom sizing ensures minimal overlap and wastage, further enhancing cost-effectiveness during long-term construction projects.

Comparison Table: Maintenance with and without PP Flooring Film

| Aspect | Without PP Film | With PP Film |

| Cleaning Effort | High, multiple cycles | Minimal, surface wiped or replaced |

| Repair Needs | Frequent scratches and touch-ups | Rare, surface remains intact |

| Labor Costs | High due to cleaning and repairs | Reduced, faster post-construction cleanup |

| Material Wastage | N/A | Low due to custom sizing and reuse |

Conclusion

Using PP flooring film during construction or renovation provides tangible cost savings by protecting surfaces from physical damage, dust, moisture, and chemical spills. Its durability, ease of application, and customizable options reduce labor and material expenses, minimizing maintenance requirements while preserving the aesthetic and functional quality of finished floors.

Recommended Articles

-

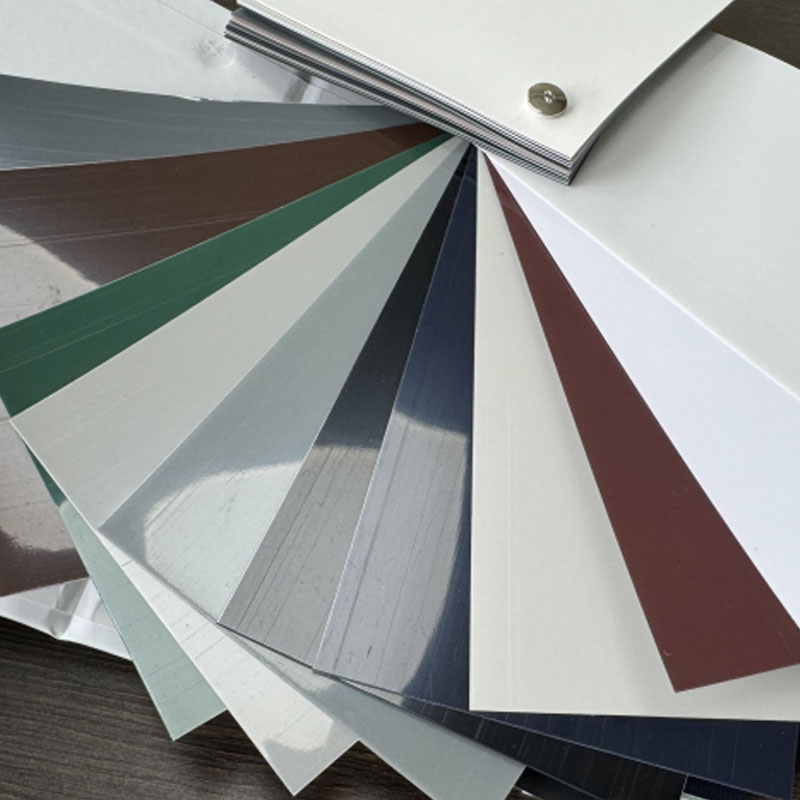

1.1 What is PP Decorative Film? PP decorative film is a type of surface material made primarily from polypropylene, a versatile and widely used thermoplastic po...

View More -

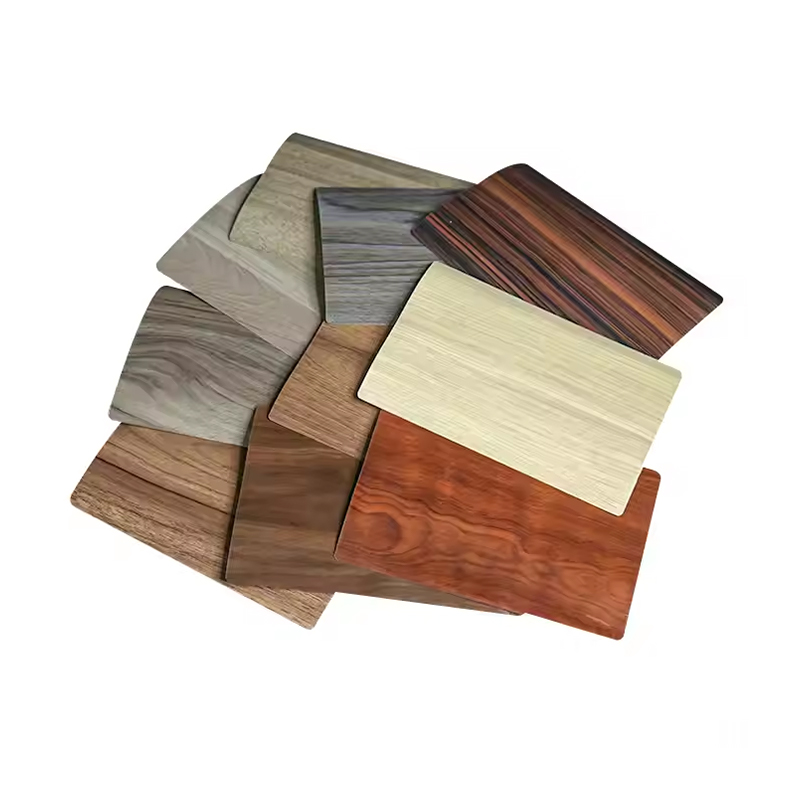

Is your furniture looking tired, outdated, or damaged? Imagine transforming it effortlessly into something stunning, durable, and uniquely yours. Enter PVC deco...

View More -

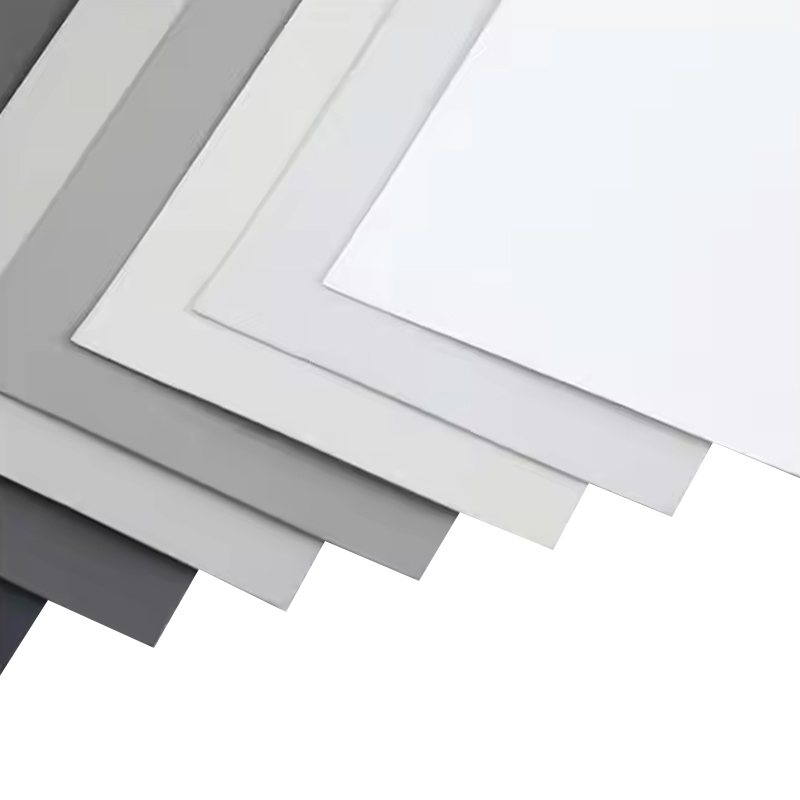

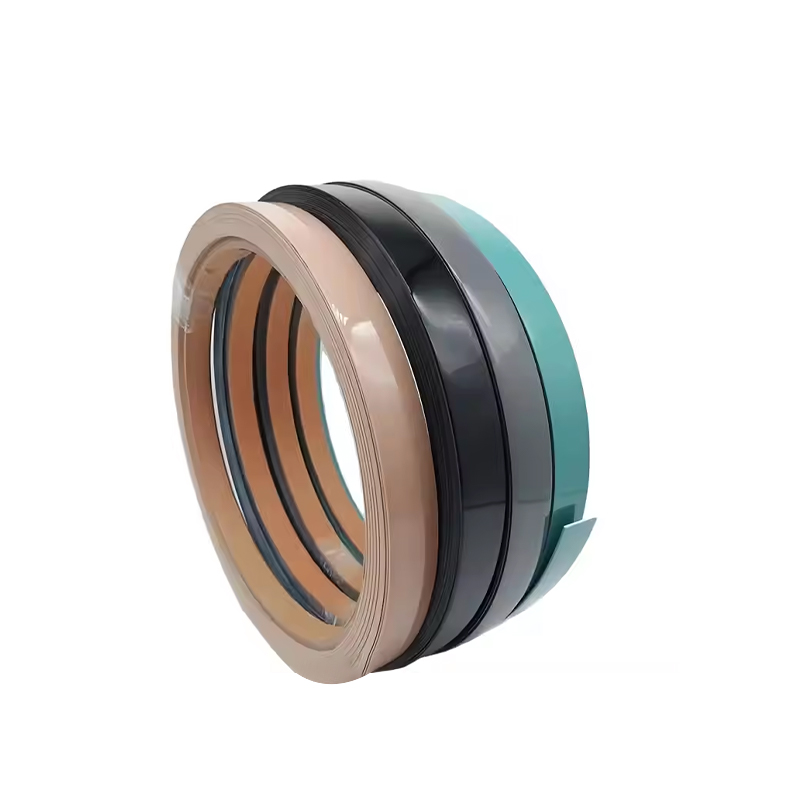

1.Introduction Edge banding is a crucial finishing process used in woodworking and furniture manufacturing to cover and seal the exposed sides of materials such...

View More

English

English Español

Español عربى

عربى