How does the surface texture of wood grain PVC film replicate the appearance of real wood?

2025-09-05

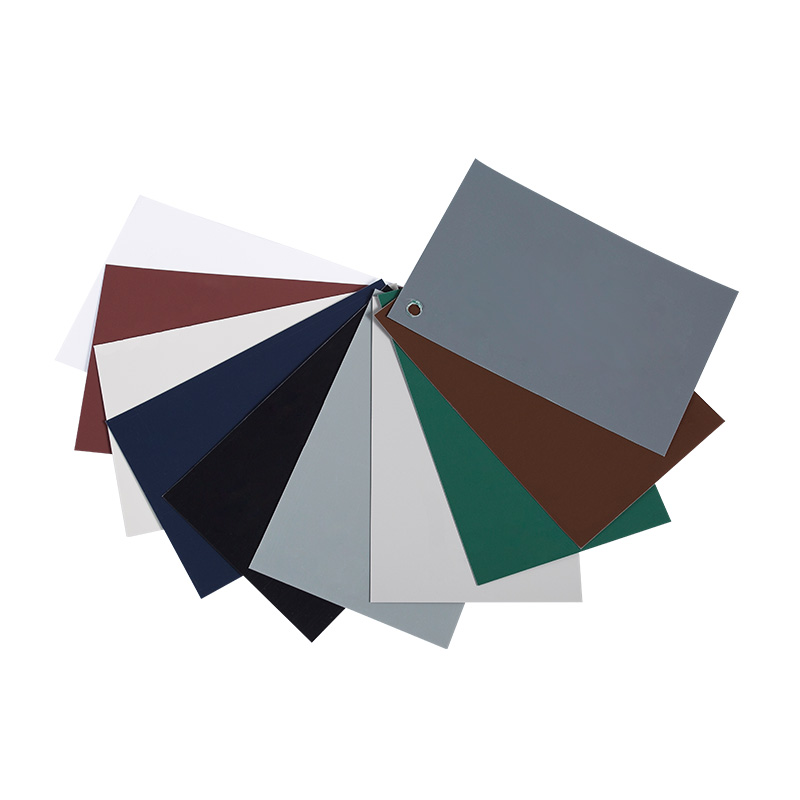

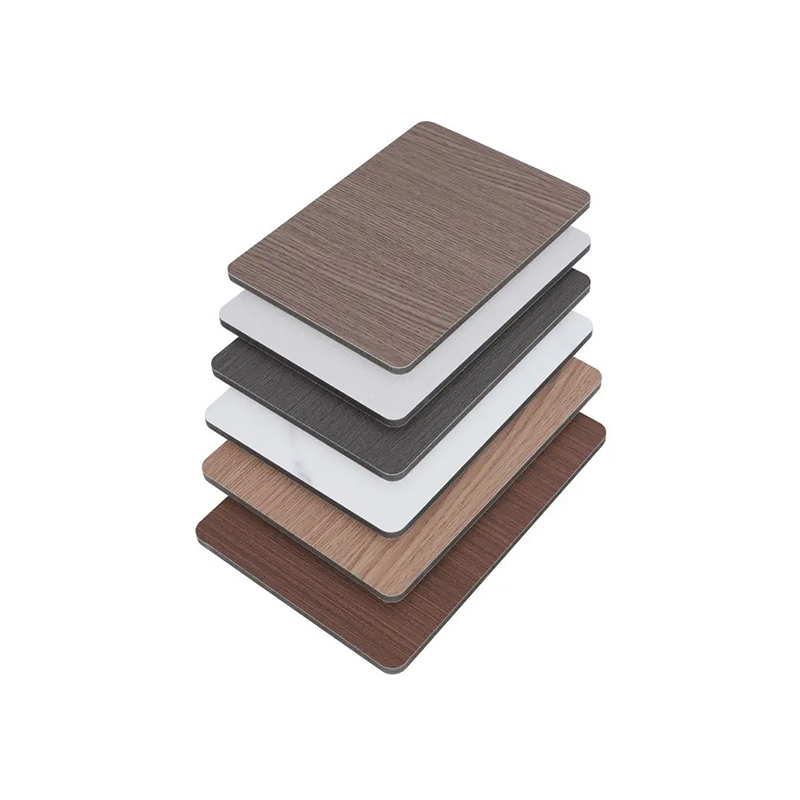

Wood grain PVC decorative film has become one of the most popular alternatives to natural wood veneer in furniture, doors, cabinets, and interior wall panels. Its realistic look and feel allow designers and manufacturers to achieve the warmth and beauty of natural wood at a fraction of the cost. But how does this synthetic film so convincingly replicate real wood? The answer lies in advanced printing, embossing, and finishing technologies that combine to mimic both the visual patterns and tactile qualities of genuine timber.

Content

1. High-Resolution Printing of Wood Patterns

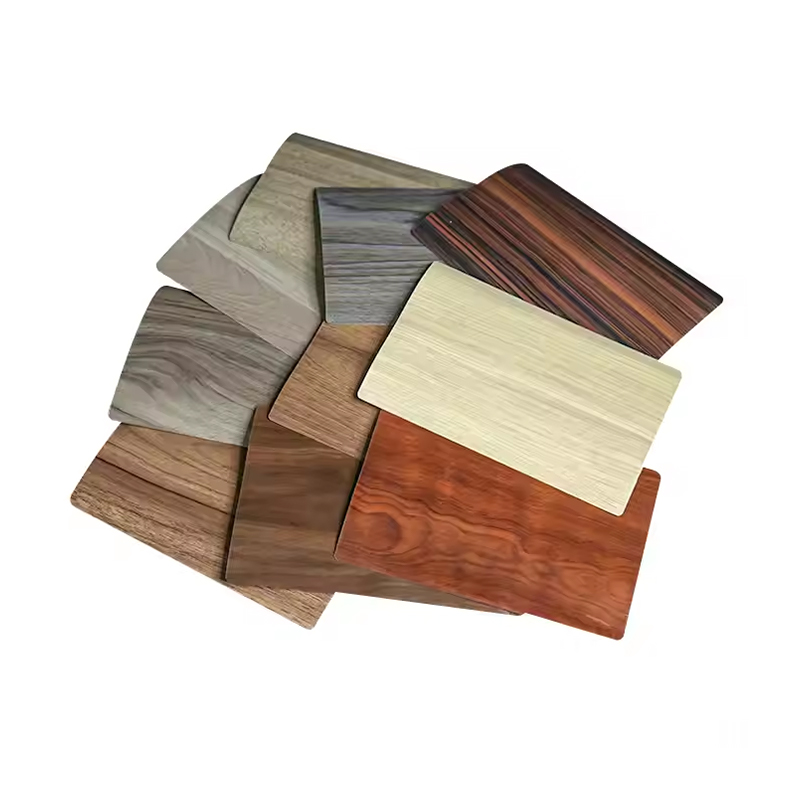

The first step in replicating wood is the creation of a detailed grain pattern. Using high-definition gravure or digital printing techniques, wood grain PVC film captures the intricate lines, knots, and natural variations found in real wood species.

- Pattern variety: Manufacturers can reproduce the look of oak, walnut, maple, cherry, and countless other woods.

- Consistency: Unlike natural wood, the film offers uniform grain without the inconsistencies or defects found in raw lumber.

- Customization: Colors and grain depth can be adjusted to match design preferences, from light birch tones to deep mahogany shades.

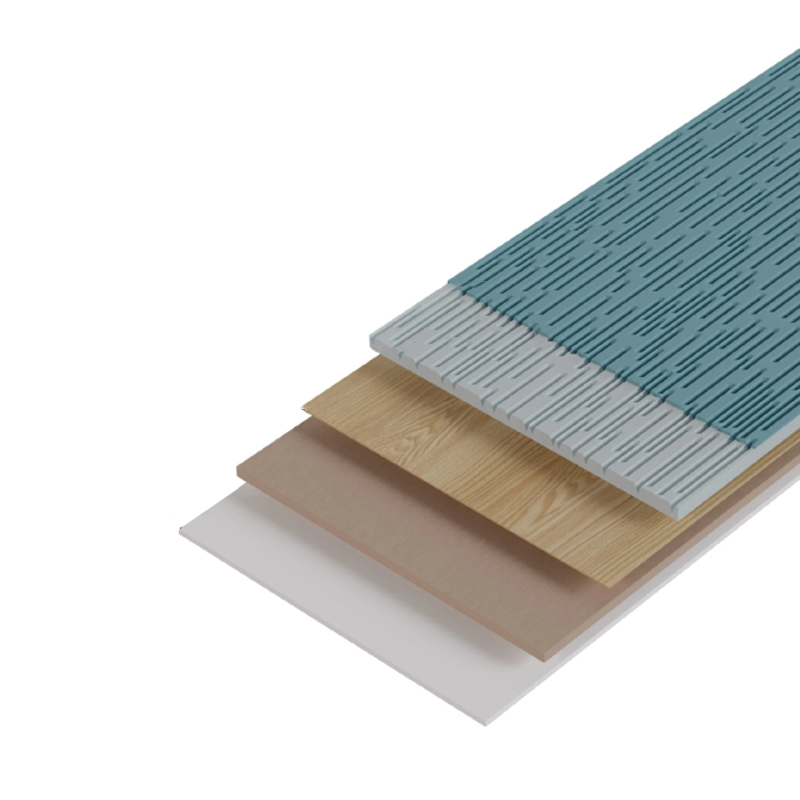

2. Embossing for 3D Surface Texture

While printing provides the visual pattern, embossing gives the film its tactile quality. During production, the film is passed through embossing rollers that imprint fine textures corresponding to the printed grain.

- Synchronized embossing: Advanced technology aligns embossing with the printed pattern, so raised areas match the visual grain, creating an authentic wood-like feel.

- Matte and gloss variations: Different embossing techniques allow for a polished, semi-gloss, or rustic matte finish, enhancing realism.

- Depth effect: The slight ridges and grooves mimic the touch of sanded or brushed wood surfaces.

3. Color Layering and Shading Effects

Natural wood has tonal variations that give it depth. To replicate this, manufacturers use multiple ink layers and shading techniques.

- Gradients and highlights: Subtle changes in tone replicate the way light interacts with wood fibers.

- Multi-pass printing: Advanced printing equipment allows for layered effects that enhance realism.

- Durability of color: UV-resistant coatings help the film retain its natural wood look over time without fading.

4. Protective Coatings for Finish and Longevity

The final surface finish of wood grain PVC film is achieved by applying protective layers. These not only provide resistance to wear but also influence the look and feel.

- Gloss control: Coatings can adjust reflectivity to simulate polished hardwood or aged, matte wood.

- Scratch and abrasion resistance: Protective coatings ensure the texture remains intact even under frequent use.

- Moisture protection: Unlike natural wood, the PVC film resists swelling or warping when exposed to humidity.

5. Advantages Over Natural Wood

The replication process provides not only realism but also practical benefits:

- Cost efficiency: More affordable than sourcing and finishing real wood.

- Sustainability: Reduces the need for timber harvesting, helping conserve natural forests.

- Design flexibility: Unlimited colors and grain patterns beyond what nature offers.

Conclusion

The convincing appearance of wood grain PVC decorative film comes from the combined use of high-resolution printing, synchronized embossing, color layering, and protective surface treatments. These techniques replicate both the visual complexity and tactile feel of real wood, making the film a practical and aesthetically pleasing choice for modern furniture and interior decoration. With added durability, moisture resistance, and design versatility, wood grain PVC film continues to bridge the gap between natural beauty and engineered performance.

Recommended Articles

-

1.1 What is PP Decorative Film? PP decorative film is a type of surface material made primarily from polypropylene, a versatile and widely used thermoplastic po...

View More -

Is your furniture looking tired, outdated, or damaged? Imagine transforming it effortlessly into something stunning, durable, and uniquely yours. Enter PVC deco...

View More -

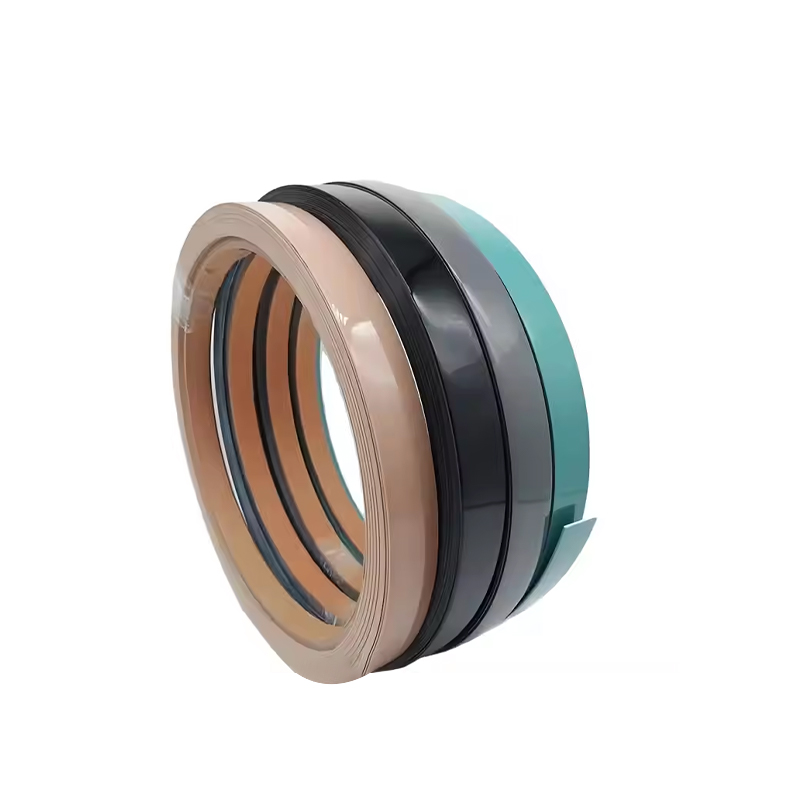

1.Introduction Edge banding is a crucial finishing process used in woodworking and furniture manufacturing to cover and seal the exposed sides of materials such...

View More

English

English Español

Español عربى

عربى