Edge Banding Suppliers

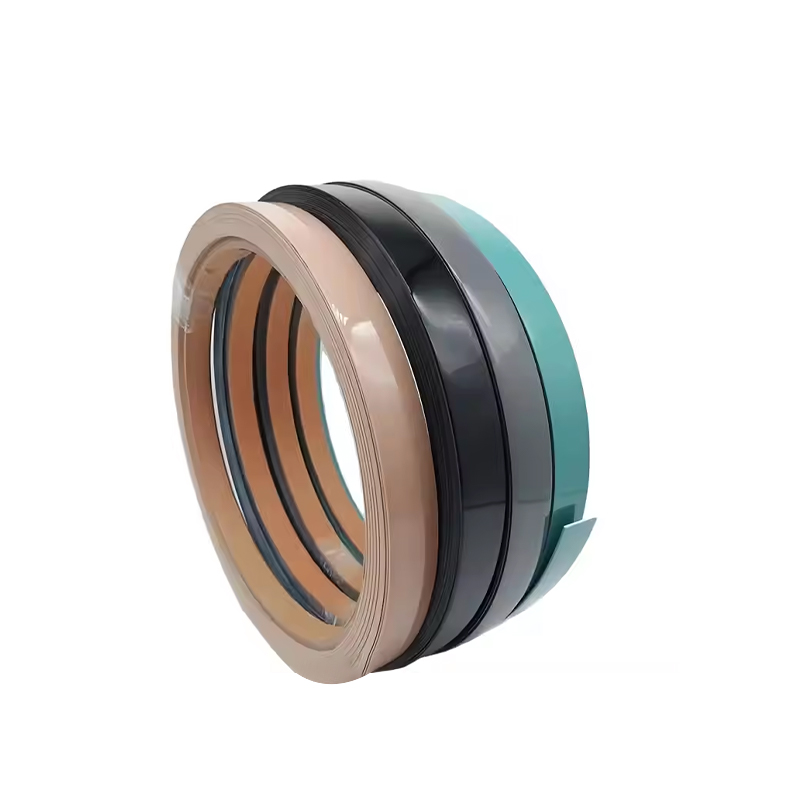

Edge banding is a material used to protect, decorate, and beautify the cross section of furniture boards. It can make a piece of furniture appear with a clear wood grain and a colorful overall effect. We can provide edge banding made of PVC and ABS materials.

About Us

Jiaxing Xuanyi International Trade Co.,Ltd is a professional decorative film manufacturer located in Jiaxing City, Zhejiang Province. As OEM/ODM Edge Banding Suppliers and Edge Banding Tape Company in China. We have our own raw material factory, calender factory, and Coating factory, forming a unique supply chain that enables us to achieve maximum cost control and offer competitive prices and high-quality products directly.

Jiaxing Xuanyi mainly engages in producing all kinds of decorative film for vacuum press, flat lamination, and profile wrapping furniture, and the interior decoration industry. Products include matte solid color series, matte wood grain series, high-gloss solid color series, high-gloss wood grain series, anti-scratch series, soft touch series, etc.

Jiaxing Xuanyi products are widely used in domestic and abroad markets as indoor and outdoor decoration materials in membrane doors, kitchen cabinets, and other furniture industries. We offer Wholesale Edge Banding Tape. Equipped with advanced facilities and professional technical experts, Jiaxing Xuanyi is committed to supplying high-quality decorative films at competitive prices.

The precise instrument, together with the cautious attitude, embodies the connotation of the “Rigorous”. Jiaxing Xuanyi adopts an international quality management mode and guarantees the quality of decorative film via advanced inspection and measurement methods. Adheres to the Value of “Profession, quality, cooperation, win-win situation”, Jiaxing Xuanyi is actively pioneering in unknowing fields through technological innovation oriented to the global market based on its long-accumulated comprehensive technological strength, to continuously offer various products that can improve people’s lives and promote the progress of the whole society.

News

-

Industry News 2026-02-28

Understanding PVC, PP, and PET Decorative Films: An Overview PVC, PP, and PET decorative films are polymer-based surface covering materials manufactured in continuous roll form and...

View More -

Self Adhesive Film Wallpaper: Installation Methods, Surface Compatibility, and Long-Term PerformanceIndustry News 2026-02-19

Material Structure and Adhesive Technology Behind Self Adhesive Film Wallpaper Self adhesive film wallpaper is manufactured as a multi-layer decorative system that integrates a pri...

View More -

Industry News 2026-02-12

ABS edge banding is widely used in modern furniture and cabinet manufacturing to protect panel edges, improve visual consistency, and extend service life. Made from acrylonitrile b...

View More

Industry Knowledge

How to Improve Edge Wrapping and Sealing Techniques for Durable, Professional Decorative Finishes

Achieving a long-lasting, flawless finish on panels, doors, and furniture surfaces depends not only on the surface material but also on how the edges are treated. Poor edge wrapping leads to peeling, lifting, and moisture ingress over time, undermining both aesthetics and durability. For projects using PETG decorative film or similar laminates, mastering edge sealing techniques is essential to delivering a product that holds up under daily wear. That’s where precision in material preparation and the right combination of tools and processes play a defining role.

The first key factor is selecting a compatible core material. Whether the application is for MDF, plywood, or particle board, the substrate edges must be properly prepared—smooth, clean, and ideally pre-sealed. Porous substrates, if left untreated, can absorb adhesives unevenly, weakening the bond at the edge. This is especially critical for vertical panels and doors, where gravity and repeated handling put added stress on the bonded areas. A solid base ensures better adhesion during wrapping and better performance in service.

The wrapping material itself must also be suited for edge use. Thinner films can stretch and tear during folding, while overly rigid materials may resist tight curves. PETG is a good candidate because of its flexibility and formability under moderate heat. Still, not all PETG films are optimized for edges, so a careful balance between thickness and surface finish is necessary. Preheating the film slightly before wrapping can reduce internal stress and improve conformity around tight radii, especially on furniture components that require crisp lines and smooth contours.

Adhesive performance is another core element. Many high-quality edge banding results come from pairing hot-melt or PUR adhesives with controlled pressure and temperature. These adhesives allow for a fast setting time and strong bond while tolerating minor imperfections in the substrate. Using a reliable edge banding machine with accurate feed control and pressure rollers ensures that the tape or film is evenly applied without trapping air bubbles. This prevents future delamination and gives a clean, finished look.

Where a dedicated edge banding tape is used instead of wrapping film, special care should be given to the overlap and trimming. Tapes must be cut cleanly and trimmed flush with the panel face to prevent snagging or lifting. Post-processing steps like edge buffing or laser edge sealing can improve durability and visual consistency, particularly in high-gloss or color-matched finishes. Whether wrapping or taping, the edge treatment should align seamlessly with the face material, contributing to a unified and high-quality appearance.

Environmental exposure is another challenge. Humidity, temperature swings, and cleaning chemicals can all affect the longevity of an edge joint. That's why it's essential to choose edge banding solutions tested for resistance to heat, water, and impact. In high-traffic spaces like kitchens, schools, or commercial furniture, these factors directly influence maintenance cycles and user satisfaction. Manufacturers who prioritize these performance characteristics in their edge banding systems are more likely to earn repeat orders and long-term trust.

Handling and storage before and during application can also affect results. Edge banding materials should be kept in a stable environment to avoid curling or deformation. Panels should be acclimated to room temperature before processing, and adhesive equipment must be properly maintained to avoid glue starvation or overheating. Even the most advanced materials can fail under poor handling conditions, so consistency in process and environment is vital.

For curved or shaped parts, edge wrapping becomes more complex. In these cases, manual techniques or soft-forming equipment are often used. Heat guns or infrared elements can be applied to pre-soften the film, while skilled operators use hand rollers or vacuum presses to press the film into grooves and contours. These techniques allow PETG film to be applied to intricate profiles without cracking or bridging, offering more design flexibility without compromising strength.

Ultimately, professional edge treatment comes down to precision and process control. From substrate prep and adhesive choice to tape selection and post-finishing, every step contributes to a visually clean and structurally sound product. High-quality edge banding not only improves the appearance of furniture and panels but also significantly extends their service life, reducing callbacks and maintenance costs. This is why we’re proud to provide edge banding tape and compatible decorative films that meet demanding design and durability standards—because it’s not just about how it looks on day one, but how well it lasts.

With years of experience supplying edge finishing materials to manufacturers across furniture and interior design sectors, we understand what makes an edge hold up through years of use. Partnering with us gives you access to dependable materials, technical guidance, and the kind of quality that helps your finished product stand out.

English

English Español

Español عربى

عربى